Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

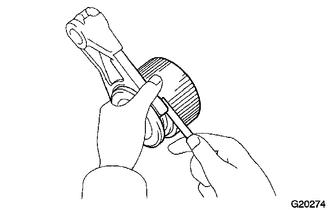

1. INSPECT REAR DIFFERENTIAL LOCK SLEEVE

(a) Install the sleeve to the differential case (LH) and check that it moves smoothly.

(b) Install the side gear to the sleeve and check that it moves smoothly.

|

(c) Using a feeler gauge, measure the clearance between the shift fork and sleeve. Maximum clearance: 0.15 to 0.35 mm (0.0059 to 0.0138 in.) |

|

2. INSPECT DIFFERENTIAL PINION AND SIDE GEAR

(a) Check that there is no damage to the differential pinion or differential side gear.

If the differential pinion and/or differential side gear is damaged, replace the differential.

3. INSPECT DIFFERENTIAL CASE

(a) Check that the differential case is not damaged.

If the differential case is damaged, replace it.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. FIX REAR DIFFERENTIAL CARRIER ASSEMBLY IN PLACE

(a) Fix the rear differential carrier assembly to the overhaul attachment.

2. INSPECT REAR DRIVE PINION COMPANION FLANGE ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

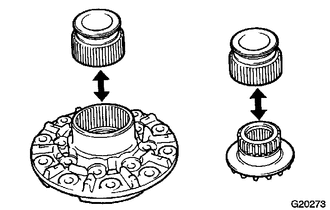

1. INSTALL DIFFERENTIAL CASE ASSEMBLY

(a) Install the rear differential side gear thrust washer to the rear differential

side gear.

(b) Install the rear differential pinio ...

Other materials about Toyota 4Runner:

Center Airbag Sensor Assembly Malfunction (B1000/31)

DESCRIPTION

The center airbag sensor assembly consists of a deceleration sensor, safing sensor,

drive circuit, diagnosis circuit, ignition control, etc.

If the center airbag sensor assembly receives signals from the deceleration sensor,

it determines whe ...

Capacity and distribution

Cargo capacity depends on the total weight of the occupants.

(Cargo capacity) = (Total load capacity) — (Total weight of occupants) Steps

for Determining Correct Load Limit-- (1)Locate the statement “The combined

weight of occupants and cargo should n ...