Toyota 4Runner: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT BRAKE BOOSTER ASSEMBLY

(a) Airtightness check

|

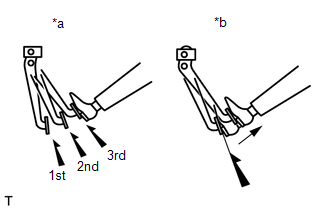

(1) Start the engine and stop it after 1 or 2 minutes. Slowly depress the brake pedal several times. If the pedal can be depressed to the floor the first time, but on the 2nd and 3rd times cannot be depressed as far, the booster is airtight. Text in Illustration

|

|

(2) Depress the brake pedal while the engine is running and stop the engine with the brake pedal depressed.

If there is no change in the pedal reserve distance while holding the pedal for 30 seconds, the booster is airtight.

(b) Operation check

|

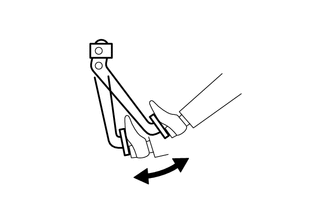

(1) Depress the brake pedal several times with the ignition switch off and check that there is no change in the pedal reserve distance when the pedal is depressed. |

|

|

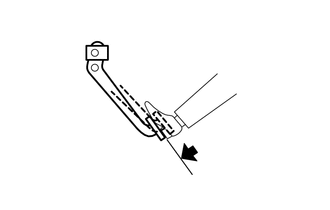

(2) Depress and hold down the pedal and start the engine. If the pedal goes down slightly, operation is normal. |

|

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Make sure to release the vacuum from the brake booster before removing the master

cylinder from the brake booster.

PROCEDURE

1. DRAIN BRAKE FLUID

NOTICE ...

Other materials about Toyota 4Runner:

Under Hood

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. GENERAL NOTES

Maintenance requirements vary depending on the country.

Check the maintenance schedule in the owner's manual supplement.

Following the maintenance schedule is mandat ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSFER ASSEMBLY

(a) Install the transfer to the transmission.

(b) Install the 8 bolts.

Torque:

24 N·m {245 kgf·cm, 18 ft·lbf}

2. INSTALL AUTOMATIC TRANSMISSION ASSEMBLY

(a) Install the automatic transmission (See ...