Toyota 4Runner: Speaker Output Short (B15C3)

DESCRIPTION

This DTC is stored when a malfunction occurs in the speakers.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B15C3 |

A short is detected in the speaker output circuit. |

|

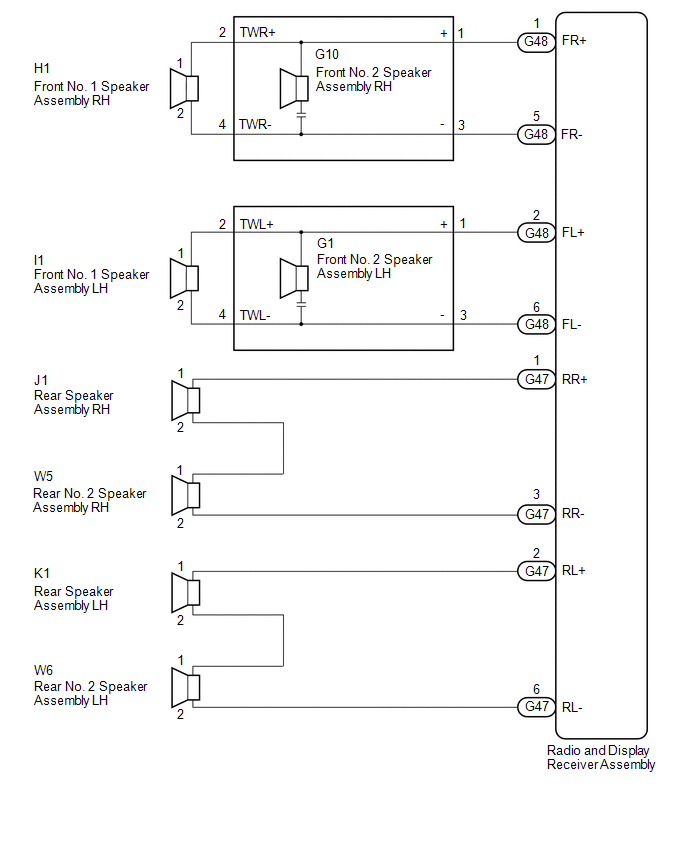

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR |

(a) Disconnect the G47 and G48 radio and display receiver assembly connectors.

(b) Disconnect the H1 and I1 front No. 1 speaker assembly connectors.

(c) Disconnect the G1 and G10 front No. 2 speaker assembly connectors.

(d) Disconnect the J1 and K1 rear speaker assembly connectors.

(e) Disconnect the W5 and W6 rear No. 2 speaker assembly connectors.

(f) Measure the resistance between the radio and display receiver assembly and body ground to check for a short circuit in the wire harness.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G47-1 (RR+) - Body ground |

Always |

10 kΩ or higher |

|

G47-2 (RL+) - Body ground |

Always |

10 kΩ or higher |

|

G47-3 (RR-) - Body ground |

Always |

10 kΩ or higher |

|

G47-6 (RL-) - Body ground |

Always |

10 kΩ or higher |

|

G48-1 (FR+) - Body ground |

Always |

10 kΩ or higher |

|

G48-2 (FL+) - Body ground |

Always |

10 kΩ or higher |

|

G48-5 (FR-) - Body ground |

Always |

10 kΩ or higher |

|

G48-6 (FL-) - Body ground |

Always |

10 kΩ or higher |

(g) Measure the resistance between each of the front No. 2 speaker assemblies and body ground to check for a short circuit in the wire harness.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G1-2 (TWL+) - Body ground |

Always |

10 kΩ or higher |

|

G1-4 (TWL-) - Body ground |

Always |

10 kΩ or higher |

|

G10-2 (TWR+) - Body ground |

Always |

10 kΩ or higher |

|

G10-4 (TWR-) - Body ground |

Always |

10 kΩ or higher |

(h) Measure the resistance between each of the rear speaker assemblies and rear No. 2 speaker assemblies to check for a short circuit in the wire harness.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

J1-2 - Body ground |

Always |

10 kΩ or higher |

|

K1-2 - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

INSPECT FRONT NO. 1 SPEAKER ASSEMBLY |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPLACE FRONT NO. 1 SPEAKER ASSEMBLY |

|

|

3. |

REPLACE FRONT NO. 2 SPEAKER ASSEMBLY |

(a) Replace the front No. 2 speaker assembly with a known good one (See page

.gif) ).

).

(b) Clear the DTCs (See page .gif) ).

).

(c) Recheck for DTCs and check that no DTCs are output (See page

.gif) ).

).

OK:

No DTCs are output.

HINT:

- Connect all the connectors to the front No. 2 speaker assemblies that were disconnected.

- When there is a possibility that either the right or left front speaker is defective, inspect by interchanging the right one with the left one.

- Perform the above inspection on both LH and RH sides.

| OK | .gif) |

END (FRONT NO. 2 SPEAKER ASSEMBLY WAS DEFECTIVE) |

|

|

4. |

INSPECT REAR SPEAKER ASSEMBLY |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPLACE REAR SPEAKER ASSEMBLY |

|

|

5. |

INSPECT REAR NO. 2 SPEAKER ASSEMBLY |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

REPLACE RADIO AND DISPLAY RECEIVER ASSEMBLY |

| NG | .gif) |

REPLACE REAR NO. 2 SPEAKER ASSEMBLY |

XM Tuner Antenna Disconnected (B15FE,B15FF)

XM Tuner Antenna Disconnected (B15FE,B15FF)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the satellite radio antenna

assembly which is connected to the stereo component tuner assembly.

DTC No.

DTC Det ...

GPS Antenna Connection Malfunction(short) (B15C0,B15C1)

GPS Antenna Connection Malfunction(short) (B15C0,B15C1)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the navigation antenna assembly.

DTC No.

DTC Detection Condition

Trouble Area

B15C0

...

Other materials about Toyota 4Runner:

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL MASTER CYLINDER RESERVOIR GROMMET

(a) Apply a light coat of lithium soap base glycol grease to 2 new master cylinder

reservoir grommets.

(b) Install the 2 master cylinder reservoir grommets to the brake master cylinder

r ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT DIFFERENTIAL SIDE GEAR SHAFT BEARING RH

(a) Using SST and a press, press in the shaft bearing.

SST: 09223-00010

(b) Using a snap ring expander, install the snap ring.

HINT:

Install the snap ring securely.

2. INST ...

.gif)