Toyota 4Runner: Disassembly

DISASSEMBLY

PROCEDURE

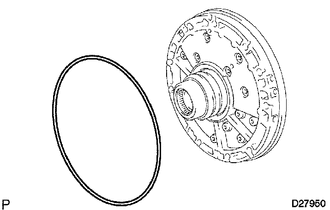

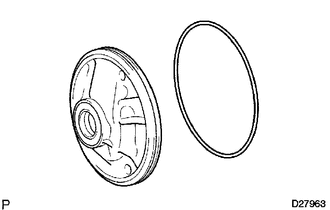

1. REMOVE AUTOMATIC TRANSMISSION CASE O-RING

|

(a) Remove the O-ring from the oil pump assembly. |

|

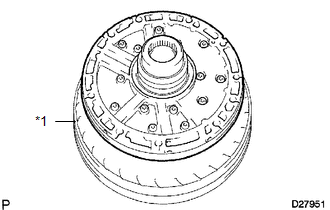

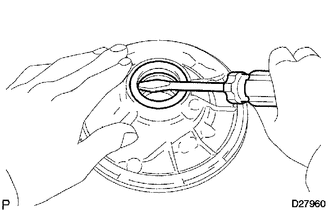

2. FIX OIL PUMP ASSEMBLY

|

(a) Place the oil pump body on the torque converter clutch. Text in Illustration

|

|

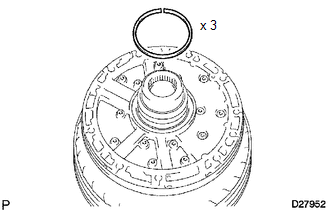

3. REMOVE CLUTCH DRUM OIL SEAL RING

|

(a) Remove the 3 oil seal rings. |

|

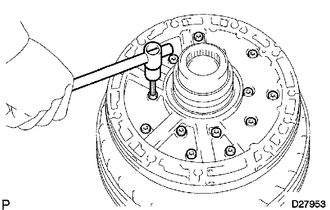

4. REMOVE STATOR SHAFT ASSEMBLY

|

(a) Remove the 14 bolts and stator shaft from the oil pump body. |

|

5. REMOVE FRONT OIL PUMP BODY O-RING

|

(a) Remove the O-ring from the oil pump body. |

|

(b) Remove the oil pump body from the torque converter clutch.

6. INSPECT FRONT OIL PUMP BODY SUB-ASSEMBLY

.gif)

7. INSPECT STATOR SHAFT ASSEMBLY

.gif)

8. INSPECT CLEARANCE OF OIL PUMP ASSEMBLY

.gif)

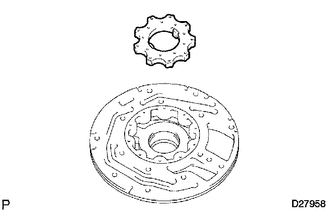

9. REMOVE FRONT OIL PUMP DRIVE GEAR

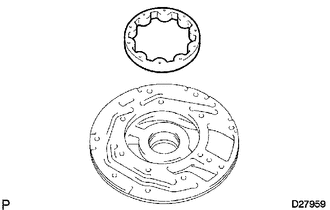

10. REMOVE FRONT OIL PUMP DRIVEN GEAR

11. REMOVE FRONT OIL PUMP OIL SEAL

|

(a) Using a screwdriver, pry out the oil seal. NOTICE: Be careful not to damage the bushing or oil pump body. |

|

Components

Components

COMPONENTS

ILLUSTRATION

...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT OIL PUMP BODY SUB-ASSEMBLY

(a) Using a dial indicator, measure the inside diameter of the oil pump

body bush.

Maximum inside diameter:

38 ...

Other materials about Toyota 4Runner:

Glossary Of Sae And Toyota Terms

GLOSSARY OF SAE AND TOYOTA TERMS

This glossary lists all SAE-J1930 terms and abbreviations used in this manual

in compliance with SAE recommendations, as well as their TOYOTA equivalents.

SAE

Abbreviation

SAE Term

TOYOTA ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL SLIDING ROOF HOUSING SUB-ASSEMBLY

(a) Temporarily install the housing with the 8 bolts (vehicle body side) and

8 nuts.

(b) Tighten the 8 nuts in alphabetical order.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(c) Tight ...

0.0092