Toyota 4Runner: Installation

INSTALLATION

PROCEDURE

1. INSTALL BRAKE BOOSTER GASKET

(a) Install a new brake booster gasket to the hydraulic brake booster.

2. INSTALL HYDRAULIC BRAKE BOOSTER ASSEMBLY

(a) Install the hydraulic brake booster assembly with the 4 nuts.

Torque:

14 N·m {145 kgf·cm, 10 ft·lbf}

|

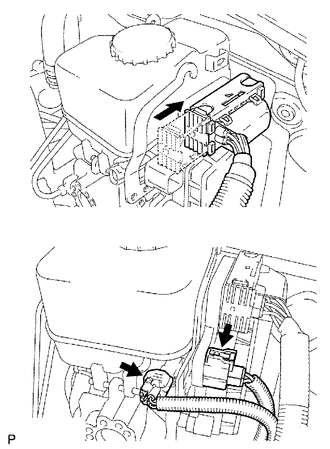

(b) Connect the 4 brake lines to the correct positions of the hydraulic brake booster assembly as shown in the illustration. HINT:

|

|

(c) Using a union nut wrench, connect the 4 brake lines to the hydraulic brake booster assembly.

Torque:

15 N·m {155 kgf·cm, 11 ft·lbf}

NOTICE:

Use the formula to calculate special torque values for situations where a union

nut wrench is combined with a torque wrench (See page

.gif) ).

).

|

(d) Connect the 3 connectors to the hydraulic brake booster assembly. |

|

3. INSTALL PUSH ROD PIN

.gif)

4. INSTALL LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

(a) Install the lower No. 1 instrument panel airbag assembly (See page

.gif) ).

).

5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

6. BLEED BRAKE SYSTEM

.gif)

7. CHECK AND ADJUST BRAKE PEDAL

(a) Check and adjust brake pedal (See page .gif) ).

).

8. INSPECT BRAKE MASTER CYLINDER OPERATION

(a) Inspect the brake master cylinder operation (See page

.gif) ).

).

9. PERFORM YAW RATE AND ACCELERATION SENSOR ZERO POINT CALIBRATION

(a) Perform the yaw rate and acceleration sensor zero point calibration (See

page .gif) ).

).

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL BRAKE BOOSTER PISTON SIB-ASSEMBLY

(a) Apply a light coat of lithium soap base glycol grease to a new piston.

(b ...

Disposal

Disposal

DISPOSAL

PROCEDURE

1. DISPOSE OF BRAKE BOOSTER ACCUMULATOR ASSEMBLY

(a) Place the brake booster accumulator assembly in a vise and cover

it with cloth.

...

Other materials about Toyota 4Runner:

If you cannot operate back door opener

If the back door opener does not operate, there may be a problem with the

back door opener system. Have the vehicle inspected by your Toyota dealer

immediately.

The following steps may be used as an emergency measure to ensure that the

back door can be ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

0.008

.png)