Toyota 4Runner: Parking Brake Switch

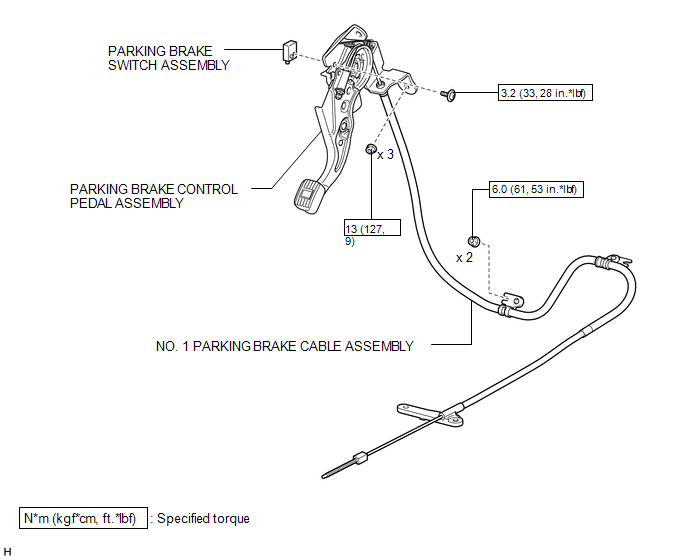

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to disable the SRS system.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

(a) Remove the lower No. 1 instrument panel airbag assembly (See page

.gif) ).

).

3. REMOVE TURN SIGNAL FLASHER ASSEMBLY

.gif)

4. REMOVE TIRE PRESSURE WARNING ECU

.gif)

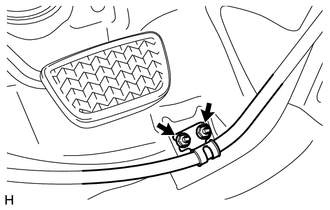

5. DISCONNECT PARKING BRAKE CONTROL PEDAL ASSEMBLY

(a) Partially remove the front floor carpet.

|

(b) Remove the 2 nuts and disconnect the No. 1 parking brake cable assembly from the body. |

|

(c) Disconnect the parking brake switch connector.

|

(d) Remove the 3 nuts and disconnect the parking brake control pedal assembly from the body. |

|

6. REMOVE PARKING BRAKE SWITCH ASSEMBLY

|

(a) Remove the screw and parking brake switch assembly from the parking brake control pedal assembly. |

|

Inspection

INSPECTION

PROCEDURE

1. INSPECT PARKING BRAKE SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

Switch connector - Switch body |

On (Shaft is not pressed) |

Below 1 Ω |

|

Off (Shaft is pressed) |

10 kΩ or higher |

.png) |

On |

.png) |

Off |

If the result is not as specified, replace the parking brake switch assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL PARKING BRAKE SWITCH ASSEMBLY

(a) Install the parking brake switch assembly to the parking brake control pedal assembly with the screw.

Torque:

3.2 N·m {33 kgf·cm, 28 in·lbf}

2. INSTALL PARKING BRAKE CONTROL PEDAL ASSEMBLY

(a) Temporarily install the parking brake control pedal assembly with the 3 nuts.

(b) Tighten the 3 nuts.

Torque:

13 N·m {127 kgf·cm, 9 ft·lbf}

(c) Connect the parking brake switch connector.

(d) Install the No. 1 parking brake cable assembly to the body with the 2 nuts.

Torque:

6.0 N·m {61 kgf·cm, 53 in·lbf}

3. INSTALL TIRE PRESSURE WARNING ECU

.gif)

4. INSTALL TURN SIGNAL FLASHER ASSEMBLY

.gif)

5. INSTALL LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

(a) Install the lower No. 1 instrument panel airbag assembly (See page

.gif) ).

).

6. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL PARKING PEDAL PAD

(a) Install the parking pedal pad.

2. INSTALL NO. 1 PARKING BRAKE CABLE ASSEMBLY

(a) Temporarily install the No. 1 parking brake cable assembly ...

Other materials about Toyota 4Runner:

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedures to troubleshoot the intuitive parking assist system.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

Rear Power Outlet Socket

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE POWER OUTLET SOCKET BEZEL (w/o Smart Key System)

(a) Put protective tape around the power outlet socket bezel.

Text in Illustration

*1

...

0.0264

.png)