Toyota 4Runner: Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

.png)

HINT:

- Centering bolts are used to mount the door hinge to the vehicle body and door. The door cannot be adjusted with the centering bolts installed. Substitute the centering bolts with standard bolts when making adjustments.

- The specified torque for standard bolts is shown in the standard bolt

chart (See page

.gif) ).

).

PROCEDURE

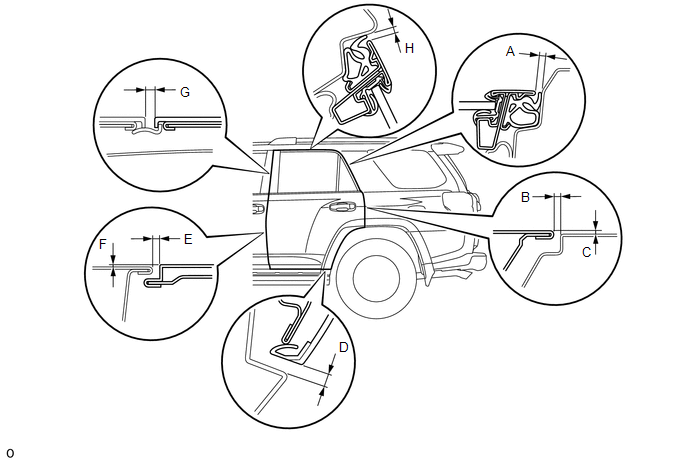

1. INSPECT REAR DOOR

(a) Check that the clearance measurements of areas A through H are within each standard range.

Standard:

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

A |

3.9 to 6.9 mm (0.154 to 0.272 in.) |

B |

3.0 to 6.0 mm (0.118 to 0.236 in.) |

|

C |

-1.5 to 1.5 mm (-0.0591 to 0.0591 in.) |

D |

5.5 to 8.5 mm (0.217 to 0.335 in.) |

|

E |

3.3 to 6.3 mm (0.130 to 0.248 in.) |

F |

-1.5 to 1.5 mm (-0.0591 to 0.0591 in.) |

|

G |

3.4 to 6.4 mm (0.134 to 0.252 in.) |

H |

4.1 to 7.0 mm (0.161 to 0.276 in.) |

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

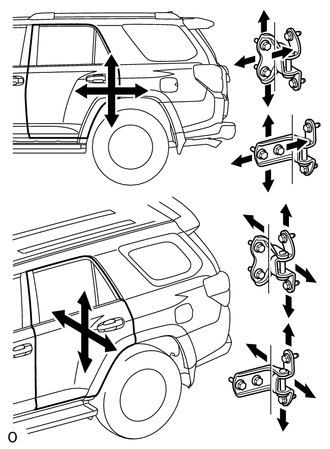

3. ADJUST REAR DOOR

|

(a) Using SST, loosen the hinge bolts on the vehicle body and adjust the door position. SST: 09812-00010 |

|

(b) Tighten the hinge bolts on the vehicle body after the adjustment.

Torque:

26 N·m {265 kgf·cm, 19 ft·lbf}

(c) Loosen the hinge bolts on the door and adjust the door position.

(d) Tighten the hinge bolts on the door after the adjustment.

Torque:

27 N·m {275 kgf·cm, 20 ft·lbf}

|

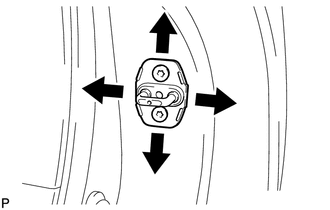

(e) Using a T40 "TORX" socket wrench, slightly loosen the striker mounting screws. |

|

(f) Using a brass bar and hammer, hit the striker to adjust its position.

(g) Using a T40 "TORX" socket wrench, tighten the striker mounting screws after the adjustment.

Torque:

23 N·m {235 kgf·cm, 17 ft·lbf}

4. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

5. INSPECT SRS WARNING LIGHT

(See page .gif) )

)

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for both the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. DISCONNECT CABLE FROM ...

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for both the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. INSTALL NO. 3 OUTSIDE M ...

Other materials about Toyota 4Runner:

CD cannot be Inserted / Played or CD is Ejected Right After Insertion

PROCEDURE

1.

CHECK IF A PROPER CD IS INSERTED

(a) Make sure that the CD is an audio CD or a CD with an MP3, WMA or AAC file,

and that it is not deformed, flawed, stained, deteriorated or otherwise defective.

OK:

CD is nor ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 1 COOLER THERMISTOR

NOTICE:

If reusing the evaporator, do not insert the sensor into a location where the

sensor was previously inserted.

(a) Insert the sensor to a location that is 1 fin to the right or left of its ...

0.0082