Toyota 4Runner: Installation

INSTALLATION

PROCEDURE

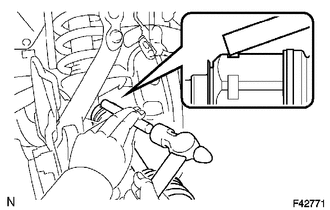

1. INSTALL FRONT DRIVE SHAFT ASSEMBLY

(a) Coat the spline of the inboard joint shaft assembly with ATF.

(b) Align the shaft splines and install the drive shaft with a brass bar and hammer.

NOTICE:

- Set the snap ring with the opening facing downward.

- Be careful not to damage the oil seal, boot or dust cover.

HINT:

Whether the inboard joint shaft is in contact with the pinion shaft or not can be confirmed from the sound or feeling when tapping in the shaft.

2. INSTALL FRONT SPEED SENSOR

.gif)

3. INSTALL LOWER BALL JOINT ATTACHMENT LH

(a) Install the lower ball joint attachment with the 2 bolts.

Torque:

160 N·m {1631 kgf·cm, 118 ft·lbf}

4. CONNECT TIE ROD END SUB-ASSEMBLY LH

.gif)

5. INSTALL FRONT AXLE SHAFT NUT

.gif)

6. INSTALL FRONT GREASE HUB CAP

.gif)

7. ADD DIFFERENTIAL OIL

.gif)

8. INSPECT DIFFERENTIAL OIL

.gif)

9. INSTALL FRONT WHEEL

Torque:

for aluminum wheel :

103 N·m {1050 kgf·cm, 76 ft·lbf}

for steel wheel :

112 N·m {1142 kgf·cm, 83 ft·lbf}

10. CHECK FRONT SPEED SENSOR SIGNAL

(a) Check the front speed sensor signal (See page

.gif) ).

).

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT DRIVE SHAFT ASSEMBLY

NOTICE:

Keep the drive shaft level while handling it.

(a) Check if there is excessive play in the outboard joint.

(b) Check if the in ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT DRIVE SHAFT DUST COVER

(a) Using SST and a press, install a new dust cover.

SST: 09527-10011

2. INSTALL SHAFT SNAP RING

(a) Install a new snap ring.

3. ...

Other materials about Toyota 4Runner:

Does not Play even after Bluetooth Audio Mode is Selected

CAUTION / NOTICE / HINT

HINT:

Even if the portable player can play audio content, it may not be able to play

via the in-vehicle device. This does not necessarily indicate a malfunction of the

in-vehicle device.

PROCEDURE

1.

CHECK ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE RADIATOR GRILLE

2. REMOVE NO. 2 ENGINE ROOM WIRE

(a) Disconnect each connector.

(b) Detach the 9 clamps to remove the No. 2 engine room wire.

3. REMOVE NO. 1 ULTRASONIC SENSOR

4. REMOVE ULTRASONIC SENSOR CLIP

...

0.025