Toyota 4Runner: Parking Brake Switch Circuit

DESCRIPTION

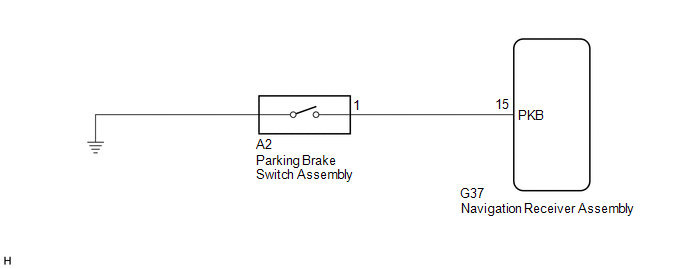

This circuit is from the parking brake switch assembly to the navigation receiver assembly.

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK VEHICLE SIGNAL (OPERATION CHECK) |

|

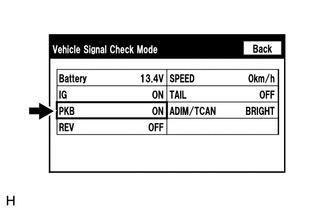

(a) Display the "Vehicle Signal Check Mode" screen (See page

|

|

(b) Check that the display changes between ON and OFF according to the parking brake operation.

OK:

|

Parking Brake Condition |

Display |

|---|---|

|

Applied |

ON |

|

Released |

OFF |

HINT:

This display is updated once per second. As a result, it is normal for the display to lag behind the actual parking brake operation.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

CHECK HARNESS AND CONNECTOR (PARKING BRAKE SWITCH ASSEMBLY - NAVIGATION RECEIVER ASSEMBLY) |

(a) Disconnect the G37 navigation receiver assembly connector.

(b) Disconnect the A2 parking brake switch assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G37-15 (PKB) - A2-1 |

Always |

Below 1 Ω |

|

G37-15 (PKB) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

INSPECT PARKING BRAKE SWITCH ASSEMBLY |

(a) Remove the parking brake switch assembly (See page

.gif) ).

).

(b) Inspect the parking brake switch assembly (See page

.gif) ).

).

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPLACE PARKING BRAKE SWITCH ASSEMBLY |

Illumination Circuit

Illumination Circuit

DESCRIPTION

Power is supplied to the navigation receiver assembly and steering pad switch

assembly illumination when the light control switch is in the tail or head position.

WIRING DIAGRAM

CAU ...

Speaker Circuit

Speaker Circuit

DESCRIPTION

If there is a short in a speaker circuit, the stereo component amplifier

assembly detects it and stops output to the speakers.

Thus sound cannot be heard from the speakers ...

Other materials about Toyota 4Runner:

Bleeding

BLEEDING

PROCEDURE

1. BLEED AIR FROM SUSPENSION FLUID

CAUTION:

Be sure to check the pipe connections and whether or not any hydraulic

circuit parts are damaged before performing work as the hydraulic circuits

become highly pressurized durin ...

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

When installing the window frame moulding, heat the vehicle body and

window frame moulding using a ...

0.0283

.gif)