Toyota 4Runner: Power Supply Voltage Malfunction (C1882/82)

DESCRIPTION

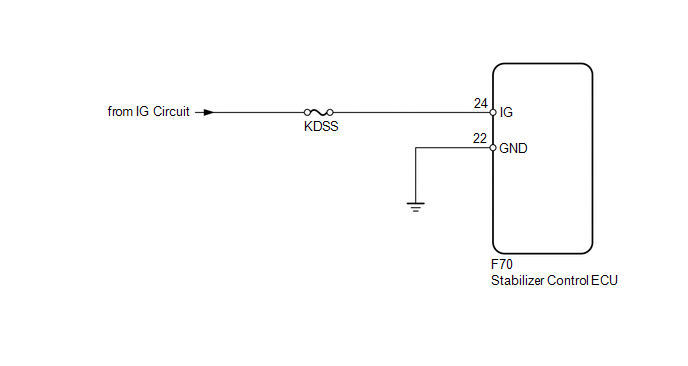

The stabilizer control ECU recognizes the ignition switch ON signal based on the voltage input to the IG terminal.

|

DTC Code |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C1882/82 |

The IG terminal voltage is 10 V or less or 16 V or higher for 0.5 seconds. |

|

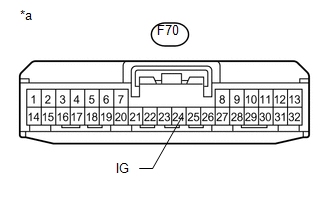

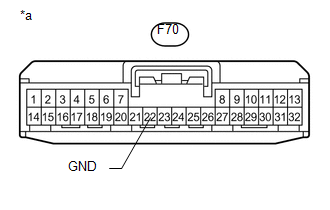

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (IG POWER SOURCE VOLTAGE) |

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / KDSS / Data List.

(f) Select the item below in the Data List, and read the value displayed on the Techstream.

KDSS|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

IG Power Source Voltage |

IG Power Source Voltage/ Min.: 0.0 V Max.: 25.5 V |

Ignition switch ON: 11 to 14 V |

- |

Standard voltage:

11 to 14 V

| NG | .gif) |

GO TO STEP 3 |

|

|

2. |

RECONFIRM DTC |

(a) Clear the DTCs (See page .gif) ).

).

(b) Check for DTCs (See page .gif) ).

).

Result

|

Result |

Proceed to |

|---|---|

|

DTC is output |

A |

|

DTC is not output |

B |

| A | .gif) |

REPLACE STABILIZER CONTROL ECU |

| B | .gif) |

USE SIMULATION METHOD TO CHECK |

|

3. |

CHECK HARNESS AND CONNECTOR (IG TERMINAL) |

(a) Disconnect the stabilizer control ECU connector.

|

(b) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (GND TERMINAL) |

(a) Disconnect the stabilizer control ECU connector.

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

REPLACE STABILIZER CONTROL ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT INDICATOR LIGHT

(a) Check that the KDSS indicator light comes on for 2 seconds when the ignition

switch is turned to ON.

If the indicator check result ...

Speed Sensor Circuit Malfunction (C1883/83)

Speed Sensor Circuit Malfunction (C1883/83)

DESCRIPTION

The stabilizer control ECU receives the speed signal from the skid control ECU

via CAN communication.

DTC Code

DTC Detection Condition

Trouble Area

...

Other materials about Toyota 4Runner:

Inspection

INSPECTION

PROCEDURE

1. INSPECT LEVEL WARNING SWITCH ASSEMBLY

HINT:

The following check should be performed with the windshield washer motor and

pump installed to the washer jar.

(a) Fill the washer jar with washer fluid.

(b) Measure the res ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL MASTER CYLINDER RESERVOIR GROMMET

(a) Apply a light coat of lithium soap base glycol grease to 2 new master cylinder

reservoir grommets.

(b) Install the 2 master cylinder reservoir grommets to the brake master cylinder

r ...

0.007

.gif)