Toyota 4Runner: Rear Power Window RH does not Operate with Rear Power Window Switch RH

DESCRIPTION

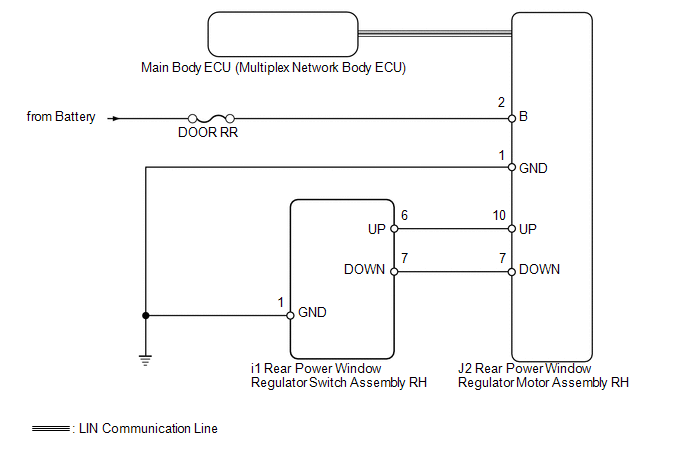

- If the manual up/down function does not operate, there may be a malfunction in the rear power window regulator switch, rear power window regulator motor, harness or connector.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

HINT:

Since the power window control system has functions that use LIN communication, first confirm that there is no malfunction in the communication system by inspecting the LIN communication functions in accordance with the "How to Proceed with Troubleshooting" procedures. Then, conduct the following inspection procedure.

PROCEDURE

|

1. |

CHECK FOR DTC (B2312) |

(a) Check if DTC B2312 is output (See page .gif) ).

).

OK:

DTC B2312 is not output.

| NG | .gif) |

GO TO DTC B2312 |

|

|

2. |

READ VALUE USING TECHSTREAM (REAR POWER WINDOW REGULATOR SWITCH) |

(a) Use the Data List to check if the rear power window regulator motor is functioning

properly (See page .gif) ).

).

RR-Door Motor

|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

RR Door P/W Up SW |

Rear power window RH manual up signal / ON or OFF |

ON: Rear power window RH manual up switch operated OFF: Rear power window RH switch not operated |

- |

|

RR Door P/W Down SW |

Rear power window RH manual down signal / ON or OFF |

ON: Rear power window RH manual down switch operated OFF: Rear power window RH switch not operated |

- |

OK:

On tester screen, each item changes between ON and OFF according to above chart.

| NG | .gif) |

GO TO STEP 4 |

|

|

3. |

PERFORM ACTIVE TEST USING TECHSTREAM (POWER WINDOW) |

(a) Select the Active Test, use the Techstream to generate a control command,

and then check that power window regulator motor operates (See page

.gif) ).

).

RR-Door Motor

|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Power Window |

Rear RH side power window |

OFF/UP/DOWN |

- |

OK:

The power window regulator motor operates normally.

| OK | .gif) |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG | .gif) |

REPLACE REAR POWER WINDOW REGULATOR MOTOR ASSEMBLY RH |

|

4. |

INSPECT REAR POWER WINDOW REGULATOR SWITCH ASSEMBLY RH |

|

(a) Remove the rear power window regulator switch (See page

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

6 (UP) - 1 (GND) |

Manual up operation |

Below 1 Ω |

|

7 (DOWN) - 1 (GND) |

Manual down operation |

Below 1 Ω |

|

6 (UP) - 1 (GND) |

Not operated |

10 kΩ or higher |

|

7 (DOWN) - 1 (GND) |

Not operated |

10 kΩ or higher |

| NG | .gif) |

REPLACE REAR POWER WINDOW REGULATOR SWITCH ASSEMBLY RH |

|

|

5. |

CHECK HARNESS AND CONNECTOR (REAR POWER WINDOW REGULATOR SWITCH ASSEMBLY RH - BODY GROUND) |

|

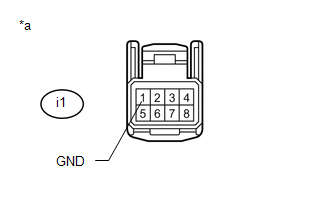

(a) Disconnect the i1 rear power window regulator switch connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

i1-1 (GND) - Body ground |

Always |

Below 1 Ω |

|

*a |

Front view of wire harness connector (to Rear Power Window Regulator Switch Assembly RH) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK HARNESS AND CONNECTOR (REAR POWER WINDOW REGULATOR SWITCH ASSEMBLY RH - REAR POWER WINDOW REGULATOR MOTOR ASSEMBLY RH) |

(a) Disconnect the i1 rear power window regulator switch connector.

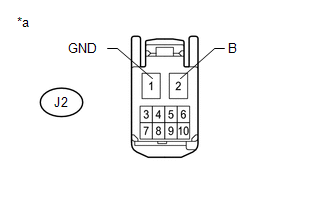

(b) Disconnect the J2 rear power window regulator motor connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

i1-6 (UP) - J2-10 (UP) |

Always |

Below 1 Ω |

|

i1-7 (DOWN) - J2-7 (DOWN) |

Always |

Below 1 Ω |

|

i1-6 (UP) - Body ground |

Always |

10 kΩ or higher |

|

i1-7 (DOWN) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

7. |

CHECK HARNESS AND CONNECTOR (REAR POWER WINDOW REGULATOR MOTOR ASSEMBLY RH - BATTERY AND BODY GROUND) |

|

(a) Disconnect the J2 rear power window regulator motor connector. |

|

(b) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

J2-2 (B) - Body ground |

Always |

11 to 14 V |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

J2-1 (GND) - Body ground |

Always |

Below 1 Ω |

|

*a |

Front view of wire harness connector (to Rear Power Window Regulator Motor Assembly RH) |

| OK | .gif) |

REPLACE REAR POWER WINDOW REGULATOR MOTOR ASSEMBLY RH |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Rear Power Window LH does not Operate with Rear Power Window Switch LH

Rear Power Window LH does not Operate with Rear Power Window Switch LH

DESCRIPTION

If the manual up/down function does not operate, there may be a malfunction

in the rear power window regulator switch, rear power window regulator motor,

harness or connect ...

Driver Side Power Window Auto Up / Down Function does not Operate with Power

Window Master Switch

Driver Side Power Window Auto Up / Down Function does not Operate with Power

Window Master Switch

DESCRIPTION

If the auto up/down function does not operate, the cause may be one or more of

the following:

The ECU in the power window regulator motor determines that the power

window re ...

Other materials about Toyota 4Runner:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

A bolt without a torque specification is shown in the standard bolt chart (See

page ).

PROCEDURE

1. INSTALL REAR NO. 2 SPOILER CLIP

HINT:

Use the same procedure to install the rear No. 2 spoiler clip on the ...

0.0187

.gif)

.png)