Toyota 4Runner: Room Temperature Sensor

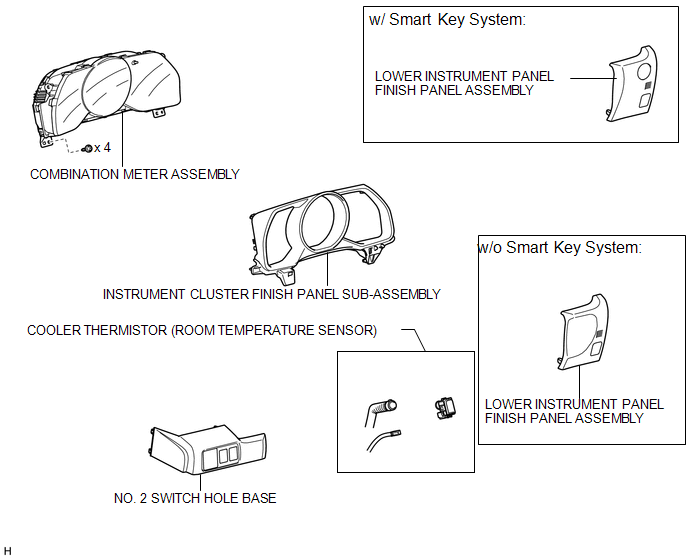

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE NO. 2 SWITCH HOLE BASE

.gif)

3. REMOVE LOWER INSTRUMENT PANEL FINISH PANEL ASSEMBLY

.gif)

4. REMOVE INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY

.gif)

5. REMOVE COMBINATION METER ASSEMBLY

.gif)

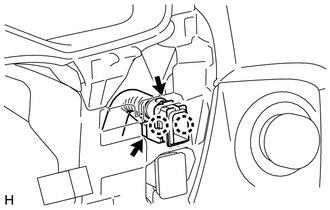

6. REMOVE COOLER THERMISTOR (ROOM TEMPERATURE SENSOR)

(a) Disconnect the connector and hose.

(b) Detach the 2 claws and remove the cooler thermistor.

Inspection

INSPECTION

PROCEDURE

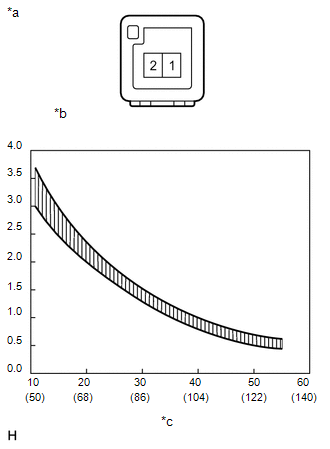

1. INSPECT COOLER THERMISTOR (ROOM TEMPERATURE SENSOR)

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

10°C (50°F) |

3.00 to 3.73 kΩ |

|

15°C (59°F) |

2.45 to 2.88 kΩ |

|

|

20°C (68°F) |

1.95 to 2.30 kΩ |

|

|

25°C (77°F) |

1.60 to 1.80 kΩ |

|

|

30°C (86°F) |

1.28 to 1.47 kΩ |

|

|

35°C (95°F) |

1.00 to 1.22 kΩ |

|

|

40°C (104°F) |

0.80 to 1.00 kΩ |

|

|

45°C (113°F) |

0.65 to 0.85 kΩ |

|

|

50°C (122°F) |

0.50 to 0.70 kΩ |

|

|

55°C (131°F) |

0.44 to 0.60 kΩ |

|

|

60°C (140°F) |

0.36 to 0.50 kΩ |

HINT:

As the temperature increases, the resistance decreases (refer to the graph).

NOTICE:

- Touching the sensor even slightly may change the resistance value. Hold the connector of the sensor.

- When measuring the resistance, make sure the sensor temperature is the same as the ambient temperature.

If the result is not as specified, replace the cooler thermistor (room temperature sensor).

Text in Illustration|

*a |

Component without harness connected (Cooler Thermistor (Room Temperature Sensor)) |

|

*b |

Resistance (kΩ) |

|

*c |

Temperature (°C(°F)) |

Installation

INSTALLATION

PROCEDURE

1. INSTALL COOLER THERMISTOR (ROOM TEMPERATURE SENSOR)

(a) Attach the 2 claws to install the cooler thermistor.

(b) Connect the connector and hose.

2. INSTALL COMBINATION METER ASSEMBLY

.gif)

3. INSTALL INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY

.gif)

4. INSTALL LOWER INSTRUMENT PANEL FINISH PANEL ASSEMBLY

.gif)

5. INSTALL NO. 2 SWITCH HOLE BASE

.gif)

6. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

Relay(w/ Ptc Heater)

Relay(w/ Ptc Heater)

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. REMOVE PTC HEATER RELAY (PTC NO. 1, PTC NO. 1, PTC NO. 3)

(a) Remove the 3 PTC heater relays from the engine room relay block. ...

Solar Sensor

Solar Sensor

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT AUTOMATIC LIGHT CONTROL SENSOR (SOLAR SENSOR)

(a) Connect the positive (+) lead of the battery to ...

Other materials about Toyota 4Runner:

Compressor Lock Sensor Circuit (B1422/22)

SYSTEM DESCRIPTION

The ECM sends the engine speed signal to the air conditioning amplifier assembly

via CAN communication.

The air conditioning amplifier assembly reads the difference between compressor

speed and engine speed. When the difference becomes ...

Remote Up / Down Function does not Operate

DESCRIPTION

When the ignition switch is ON and the window lock switch is off, the multiplex

network master switch sends remote up/down signals to each power window regulator

motor via the LIN communication line.

PROCEDURE

1.

CHECK ...

0.025