Toyota 4Runner: Solar Sensor

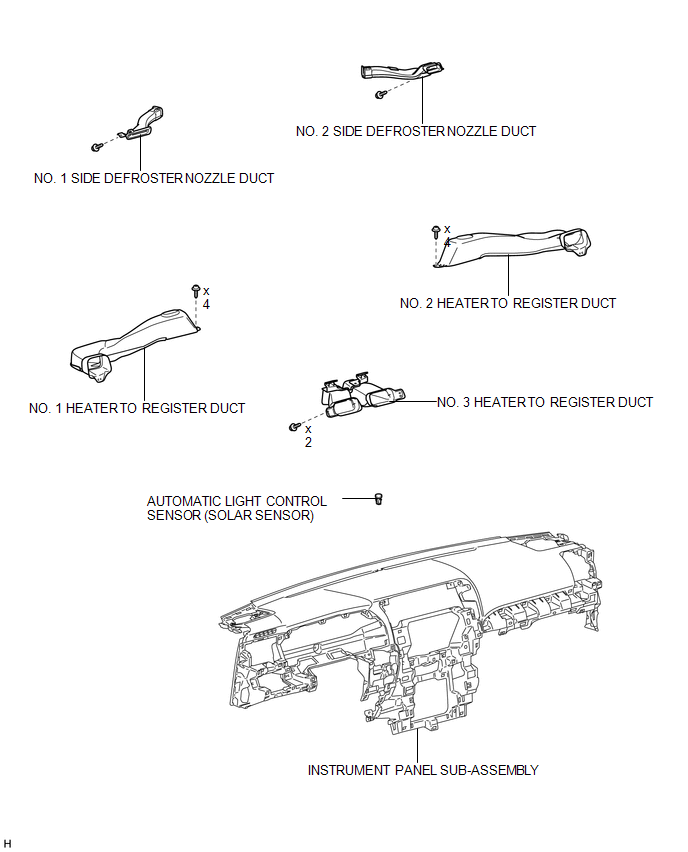

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

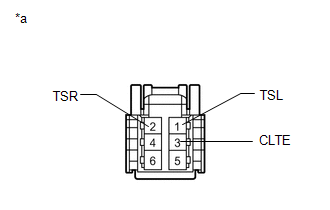

1. INSPECT AUTOMATIC LIGHT CONTROL SENSOR (SOLAR SENSOR)

|

(a) Connect the positive (+) lead of the battery to terminal 6 and the negative (-) lead to terminal 3, and then measure the voltage according to the value(s) in the table below. Standard Voltage:

HINT:

NOTICE: The connection procedure for using a digital tester, such as a TOYOTA electrical tester, is shown above. If the result is not as specified, replace the automatic light control sensor. Text in Illustration

|

|

Removal

REMOVAL

PROCEDURE

1. REMOVE INSTRUMENT PANEL SUB-ASSEMBLY

(a) Remove the instrument panel sub-assembly (See page

.gif) ).

).

2. REMOVE NO. 1 HEATER TO REGISTER DUCT

.gif)

3. REMOVE NO. 2 HEATER TO REGISTER DUCT

.gif)

4. REMOVE NO. 1 SIDE DEFROSTER NOZZLE DUCT

.gif)

5. REMOVE NO. 2 SIDE DEFROSTER NOZZLE DUCT

.gif)

6. REMOVE NO. 3 HEATER TO REGISTER DUCT

.gif)

7. REMOVE AUTOMATIC LIGHT CONTROL SENSOR (SOLAR SENSOR)

.png)

(a) Disconnect the connector.

(b) Detach the 2 claws and remove the sensor.

Installation

INSTALLATION

PROCEDURE

1. INSTALL AUTOMATIC LIGHT CONTROL SENSOR (SOLAR SENSOR)

.png)

(a) Attach the 2 claws to install the sensor.

(b) Connect the connector.

2. INSTALL NO. 3 HEATER TO REGISTER DUCT

.gif)

3. INSTALL NO. 2 SIDE DEFROSTER NOZZLE DUCT

.gif)

4. INSTALL NO. 1 SIDE DEFROSTER NOZZLE DUCT

.gif)

5. INSTALL NO. 2 HEATER TO REGISTER DUCT

.gif)

6. INSTALL NO. 1 HEATER TO REGISTER DUCT

.gif)

7. INSTALL INSTRUMENT PANEL SUB-ASSEMBLY

(a) Install the instrument panel sub-assembly (See page

.gif) ).

).

Room Temperature Sensor

Room Temperature Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized ...

Other materials about Toyota 4Runner:

USB Media Malfunction (B1585)

DESCRIPTION

This DTC is stored when a malfunction occurs in a connected device.

DTC No.

DTC Detection Condition

Trouble Area

B1585

When one of the conditions below is met:

A non mass- ...

Disassembly

DISASSEMBLY

PROCEDURE

1. SECURE VANE PUMP ASSEMBLY

(a) Using SST, secure the vane pump in a vise.

SST: 09630-00014

09631-00132

2. REMOVE SUCTION PORT UNION

(a) Remove the bolt and ...

0.0064