Toyota 4Runner: Transmission Wire

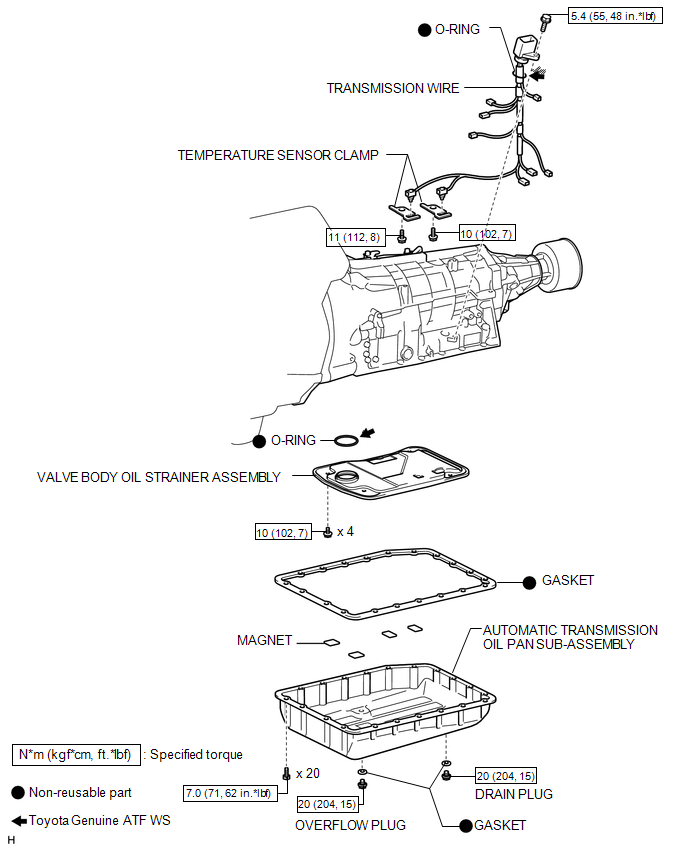

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DRAIN AUTOMATIC TRANSMISSION FLUID

(a) Remove the drain plug and gasket, and drain ATF.

(b) Install a new gasket and the drain plug.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

2. REMOVE AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY

|

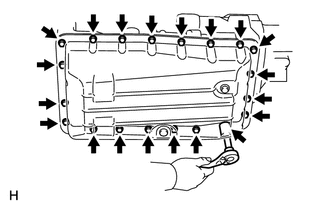

(a) Remove the 20 bolts, oil pan and gasket from the transmission. NOTICE: Some fluid will remain in the oil pan. Remove all the pan bolts, and carefully remove the oil pan assembly. |

|

(b) Examine the particles in the pan.

(1) Remove the 4 magnets and use them to collect steel particles. Carefully inspect the foreign matter and particles in the pan and on the magnets to anticipate the type of wear you will find in the transmission.

Steel (magnetic): bearing, gear and clutch plate wear

Brass (non-magnetic): bush wear

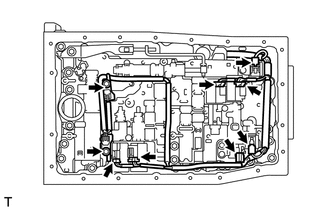

3. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

|

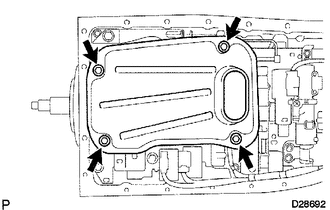

(a) Remove the 4 bolts and oil strainer. NOTICE: Be careful as some fluid may leak out of the oil strainer. |

|

(b) Remove the O-ring from the oil strainer.

4. DISCONNECT TRANSMISSION WIRE

(a) Remove the 2 bolts and 2 temperature sensor clamps.

(b) Disconnect the 2 ATF temperature sensors.

(c) Disconnect the 7 connectors from the solenoid valves.

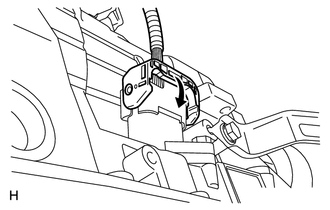

5. REMOVE TRANSMISSION WIRE

(a) Disconnect the wire connector.

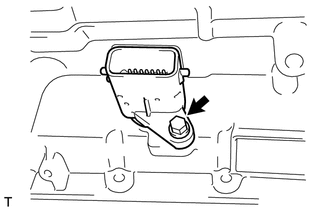

(1) Detach the claw, press down the lever, and then disconnect the transmission wire connector.

|

(b) Remove the bolt and pull out the transmission wire. |

|

Inspection

INSPECTION

PROCEDURE

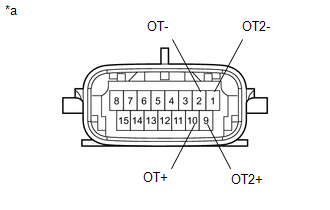

1. INSPECT TRANSMISSION WIRE (ATF TEMPERATURE SENSOR)

(a) Measure the resistance according to the value(s) in the table below.

Standard resistance:

|

Tester Connection |

ATF Temperature |

Specified Condition |

|---|---|---|

|

2 (OT-) - 10 (OT+) |

10°C (50°F) |

5 to 8 kΩ |

|

2 (OT-) - 10 (OT+) |

25°C (77°F) |

2.5 to 4.5 kΩ |

|

2 (OT-) - 10 (OT+) |

110°C (230°F) |

0.22 to 0.28 kΩ |

|

1 (OT2-) - 9 (OT2+) |

10°C (50°F) |

5 to 8 kΩ |

|

1 (OT2-) - 9 (OT2+) |

25°C (77°F) |

2.5 to 4.5 kΩ |

|

1 (OT2-) - 9 (OT2+) |

110°C (230°F) |

0.22 to 0.28 kΩ |

|

*a |

Component without harness connected (Transmission Wire) |

HINT:

If the resistance is out of the specified range at one of the ATF temperatures shown in the table below, the driveability of the vehicle may decrease.

Resistance (Reference):

|

ATF Temperature |

Specified Condition |

|---|---|

|

10°C (50°F) |

5 to 8 kΩ |

|

25°C (77°F) |

2.5 to 4.5 kΩ |

|

110°C (230°F) |

0.22 to 0.28 kΩ |

If the result is not as specified, replace the transmission wire.

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION WIRE

(a) Coat a new O-ring with ATF and install it to the transmission wire connector.

(b) Install the transmission wire with the bolt.

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

|

(c) Connect the transmission wire connector. HINT: Push up the lever until the claw of the transmission wire connector makes a connection sound. |

|

2. CONNECT TRANSMISSION WIRE

|

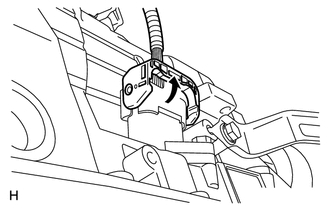

(a) Connect the 7 connectors to the solenoid valves. |

|

(b) Connect the 2 ATF temperature sensors with the 2 clamps and 2 bolts.

Torque:

for bolt A :

10 N·m {102 kgf·cm, 7 ft·lbf}

for bolt B :

11 N·m {112 kgf·cm, 8 ft·lbf}

Text in Illustration|

*1 |

Orange |

|

*2 |

Blue |

HINT:

Each bolt length is indicated below.

12 mm (0.472 in.) for bolt A

36 mm (1.41 in.) for bolt B

3. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

(a) Coat a new O-ring with ATF and install it to the oil strainer.

(b) Install the oil strainer with the 4 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

4. INSTALL AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY

NOTICE:

Remove the gasket and be careful not to spill oil on the contacting surfaces of the transmission case and oil pan.

(a) Install a new gasket and the oil pan with the 20 bolts.

Torque:

7.0 N·m {71 kgf·cm, 62 in·lbf}

5. ADD AUTOMATIC TRANSMISSION FLUID

(a) Add automatic transmission fluid (see page

.gif) ).

).

Transmission Control Cable

Transmission Control Cable

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE CONSOLE BOX ASSEMBLY

(a) Remove the console box assembly (See page

).

2. REMOVE TRANSMISSION CONTROL CABLE ASSEM ...

Other materials about Toyota 4Runner:

Rear Shock Absorber(w/o Reas)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. REMOVE REAR SHOC ...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

DTC Code

Detection Item

See page

11

Short in Motor LH

12

Short in Motor RH

21

Short to ...

0.0137

.png)