Toyota 4Runner: Washer Fluid Level Warning Switch Circuit

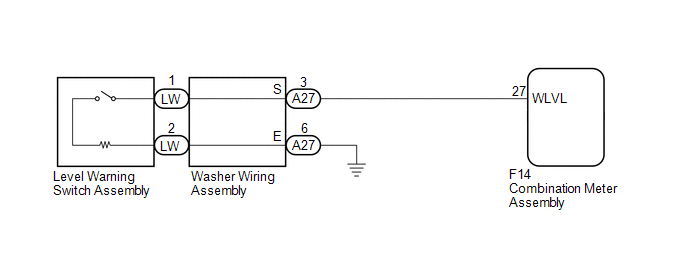

DESCRIPTION

When the volume of washer fluid decreases to below a certain level (when the level warning switch is turned on), the multi-information display in the combination meter assembly displays "LOW WASHER FLUID" to warn the driver.

WIRING DIAGRAM

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (WASHER SWITCH) |

(a) Use the Data List to check if the level warning switch assembly is functioning

properly (See page .gif) ).

).

Combination Meter

|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Washer Switch |

Level warning switch / ON or OFF |

ON: Washer jar and tank empty OFF: Washer jar and tank full |

- |

OK:

On the Techstream screen, each item changes between ON and OFF according to the above chart.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

INSPECT LEVEL WARNING SWITCH ASSEMBLY |

(a) Inspect the level warning switch assembly (See page

.gif) ).

).

| NG | .gif) |

REPLACE WASHER FLUID LEVEL WARNING SWITCH ASSEMBLY |

|

|

3. |

CHECK WASHER WIRING ASSEMBLY |

(a) Disconnect the A27 and LW washer wiring assembly connectors.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A27-3 (S) - LW-1 |

Always |

Below 1 Ω |

|

A27-6 (E) - LW-2 |

Always |

Below 1 Ω |

|

A27-3 (S) or LW-1 - Body ground |

Always |

10 kΩ or higher |

|

A27-6 (E) or LW-2 - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPLACE WASHER WIRING ASSEMBLY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (LEVEL WARNING SWITCH ASSEMBLY - COMBINATION METER ASSEMBLY AND BODY GROUND) |

(a) Disconnect the A27 washer wiring assembly connector.

(b) Disconnect the F14 combination meter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A27-3 (S) - F14-27 (WLVL) |

Always |

Below 1 Ω |

|

A27-6 (E) - Body ground |

Always |

Below 1 Ω |

|

A27-3 (S) or F14-27 (WLVL) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Rear Washer does not Operate

Rear Washer does not Operate

DESCRIPTION

The windshield wiper switch controls the rear washer motor and pump.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before perf ...

Wiper Switch

Wiper Switch

...

Other materials about Toyota 4Runner:

Portable Player cannot be Registered

CAUTION / NOTICE / HINT

HINT:

Some versions of "Bluetooth" compatible audio players may not function, or the

function may be limited using the radio and display receiver assembly, even if the

portable audio player itself can play files (See pag ...

Precaution

PRECAUTION

1. IGNITION SWITCH EXPRESSIONS

HINT:

The type of ignition switch used on this model differs according to the specifications

of the vehicle. The expressions listed in the table below are used in this section.

Expression

Ig ...

0.0073

.gif)