Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

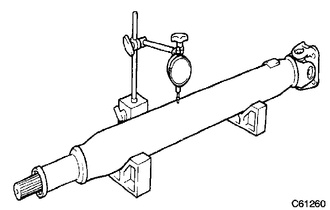

1. INSPECT PROPELLER SHAFT ASSEMBLY

|

(a) Using a dial indicator, check the propeller shaft runout. Maximum runout: 0.4 mm (0.0157 in.) If the shaft runout is more than the maximum, replace the shaft. |

|

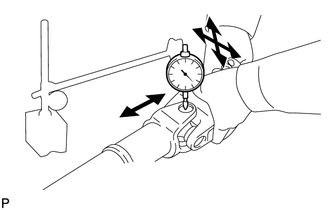

2. INSPECT REAR PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

NOTICE:

Be careful not to grip the propeller shaft tube too tightly in a vise as this will cause deformation.

(a) Check the spider bearings for wear or damage.

If necessary, replace the spider bearing.

|

(b) Check the spider bearing axial play by turning the yoke while holding the shaft tightly. Maximum bearing axial play: 0 mm (0 in.) If the axial play is more than the maximum, replace the spider bearing. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE PROPELLER SHAFT ASSEMBLY

(a) Place matchmarks on the propeller shaft flange and differential flange.

Text in Illustration

*a

...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

HINT:

Use the same procedure for all rear propeller shaft universal joint spider bearing.

(a) Apply ...

Other materials about Toyota 4Runner:

Inspection

INSPECTION

PROCEDURE

1. CHECK BRAKE CYLINDER AND PISTON

(a) Check the cylinder bore and piston for rust or scoring.

If necessary, replace the disc brake cylinder assembly.

2. CHECK PAD LINING THICKNESS

(a) Using a ruler, measure the pad lining ...

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

PROCEDURE

1. INSTALL PLUG

(a) Using the SST and a hammer, install a new plug.

SST: 09950-60010

09951-00450

SST: 09950-70010

09951-07100

2. INSTALL FRO ...