Toyota 4Runner: Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT DRIVE SHAFT ASSEMBLY

(a) Coat the spline of the inboard joint shaft assembly with ATF.

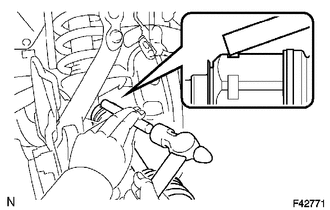

(b) Align the shaft splines and install the drive shaft with a brass bar and hammer.

NOTICE:

- Set the snap ring with the opening facing downward.

- Be careful not to damage the oil seal, boot or dust cover.

HINT:

Whether the inboard joint shaft is in contact with the pinion shaft or not can be confirmed from the sound or feeling when tapping in the shaft.

2. INSTALL FRONT SPEED SENSOR

.gif)

3. INSTALL LOWER BALL JOINT ATTACHMENT LH

(a) Install the lower ball joint attachment with the 2 bolts.

Torque:

160 N·m {1631 kgf·cm, 118 ft·lbf}

4. CONNECT TIE ROD END SUB-ASSEMBLY LH

.gif)

5. INSTALL FRONT AXLE SHAFT NUT

.gif)

6. INSTALL FRONT GREASE HUB CAP

.gif)

7. ADD DIFFERENTIAL OIL

.gif)

8. INSPECT DIFFERENTIAL OIL

.gif)

9. INSTALL FRONT WHEEL

Torque:

for aluminum wheel :

103 N·m {1050 kgf·cm, 76 ft·lbf}

for steel wheel :

112 N·m {1142 kgf·cm, 83 ft·lbf}

10. CHECK FRONT SPEED SENSOR SIGNAL

(a) Check the front speed sensor signal (See page

.gif) ).

).

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT DRIVE SHAFT ASSEMBLY

NOTICE:

Keep the drive shaft level while handling it.

(a) Check if there is excessive play in the outboard joint.

(b) Check if the in ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT DRIVE SHAFT DUST COVER

(a) Using SST and a press, install a new dust cover.

SST: 09527-10011

2. INSTALL SHAFT SNAP RING

(a) Install a new snap ring.

3. ...

Other materials about Toyota 4Runner:

Wireless Door Lock Tuner Circuit Malfunction (B1242)

DESCRIPTION

The door lock receiver is used to receive electrical waves relating to the entry

functions of the smart key system (for Entry Function). The certification ECU decodes

the requested smart key system (for Entry Function) operation by identifying ...

Transmission Control Switch Circuit

DESCRIPTION

After moving the shift lever to S, it is possible to switch the shift range between

"1" (S1 range) and "5" (S5 range) using the transmission control switch.

Shifting to "+" once raises the shift range by one, and s ...