Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

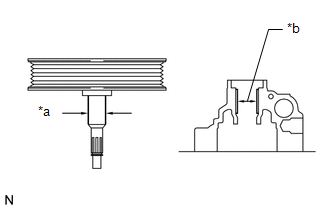

1. INSPECT VANE PUMP SHAFT AND BUSH IN VANE PUMP FRONT HOUSING

|

(a) Using a micrometer, measure the outer diameter of the vane pump shaft. Text in Illustration

|

|

(b) Using a vernier caliper, measure the inner diameter of the vane pump front housing bush.

(c) Calculate the oil clearance.

Oil clearance = Inner diameter of the bush - Outer diameter of the shaft

Maximum oil clearance:

0.07 mm (0.00276 in.)

If the oil clearance is more than the maximum, replace the vane pump assembly.

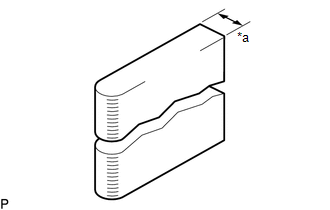

2. INSPECT VANE PUMP ROTOR AND VANE PUMP PLATE

|

(a) Using a micrometer, measure the thickness of the vane pump plates. Standard thickness: 1.405 to 1.411 mm (0.0554 to 0.0555 in.) Text in Illustration

If the thickness is not as specified, replace the vane pump assembly. |

|

|

(b) Using a feeler gauge, measure the clearance between the side face of the vane pump rotor groove and the vane pump plate. Maximum clearance: 0.025 mm (0.00098 in.) Text in Illustration

If the clearance is more than the maximum, replace the vane pump assembly. |

|

3. INSPECT PRESSURE PORT UNION

If the union seat in the pressure port union is severely damaged, it may cause fluid leakage. In that case, replace the vane pump assembly.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

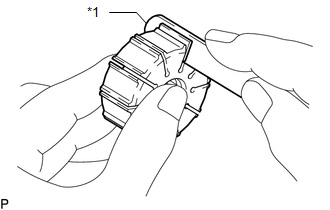

1. SECURE VANE PUMP ASSEMBLY

(a) Using SST, secure the vane pump in a vise.

SST: 09630-00014

09631-00132

2. RE ...

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

When installing parts, coat the parts indicated by arrows with power steering

fluid (See page ).

PROCEDURE

1. INSTALL VANE PUMP HOUSING OIL SEAL

(a) ...

Other materials about Toyota 4Runner:

Parking Brake Switch Circuit

DESCRIPTION

This circuit is from the parking brake switch assembly to the navigation receiver

assembly.

WIRING DIAGRAM

PROCEDURE

1.

CHECK VEHICLE SIGNAL (OPERATION CHECK)

(a) Display the "Vehicle Signal ...

Electronic Circuit Inspection Procedure

ELECTRONIC CIRCUIT INSPECTION PROCEDURE

1. BASIC INSPECTION

(a) WHEN MEASURING RESISTANCE OF ELECTRONIC PARTS

(1) Unless otherwise stated, all resistance measurements should be made at an

ambient temperature of 20°C (68°F). Resistance measurements may b ...

0.0083