Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

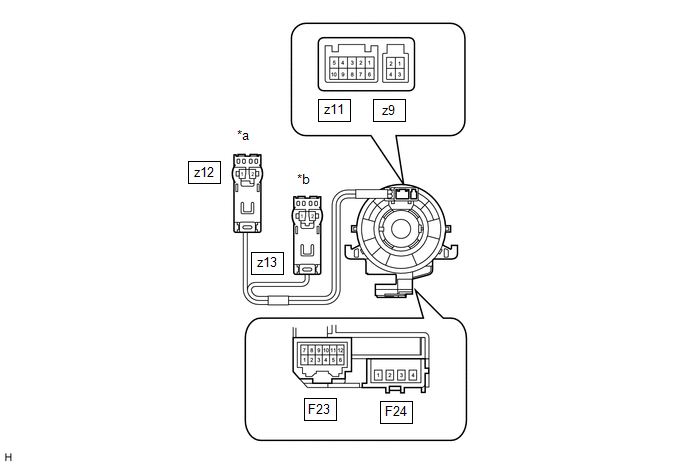

1. INSPECT SPIRAL CABLE SUB-ASSEMBLY

(a) If there are any defects as mentioned below, replace the spiral cable with a new one:

Scratches, cracks, dents or chips in the connector or spiral cable.

(b) Check the spiral cable.

Text in Illustration

Text in Illustration

|

*a |

Orange |

|

*b |

Black |

(1) Set the spiral cable to the center position (See page

.gif) ).

).

(2) After setting the spiral cable to the center position, rotate the spiral cable 2.5 times clockwise and measure the resistance according to the value(s) in the table below. Then rotate the spiral cable 5 times counterclockwise and measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F24-1 - z12-2 |

Always |

Below 1 Ω |

|

F24-2 - z12-1 |

Always |

Below 1 Ω |

|

F24-3 - z13-2 |

Always |

Below 1 Ω |

|

F24-4 - z13-1 |

Always |

Below 1 Ω |

|

F23-6 - z11-10 |

Always |

Below 1 Ω |

|

F23-5 - z11-9 |

Always |

Below 1 Ω |

|

F23-4 - z11-8 |

Always |

Below 1 Ω |

|

F23-3 - z11-7 |

Always |

Below 1 Ω |

|

F23-2 - z11-6 |

Always |

Below 1 Ω |

|

F23-1 - z9-3 |

Always |

Below 1 Ω |

|

F23-12 - z11-5 |

Always |

Below 1 Ω |

|

F23-11 - z11-4 |

Always |

Below 1 Ω |

|

F23-10 - z11-3 |

Always |

Below 1 Ω |

|

F23-9 - z11-2 |

Always |

Below 1 Ω |

|

F23-8 - z11-1 |

Always |

Below 1 Ω |

|

F23-7 - z9-1 |

Always |

Below 1 Ω |

(3) After setting the spiral cable to the center position, rotate the spiral cable 2.5 times clockwise. Then, while rotating the spiral cable 5 times counterclockwise, measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F24-1 - z12-2 |

Always |

Below 1 Ω |

|

F24-2 - z12-1 |

Always |

Below 1 Ω |

|

F24-3 - z13-2 |

Always |

Below 1 Ω |

|

F24-4 - z13-1 |

Always |

Below 1 Ω |

|

F23-6 - z11-10 |

Always |

Below 1 Ω |

|

F23-5 - z11-9 |

Always |

Below 1 Ω |

|

F23-4 - z11-8 |

Always |

Below 1 Ω |

|

F23-3 - z11-7 |

Always |

Below 1 Ω |

|

F23-2 - z11-6 |

Always |

Below 1 Ω |

|

F23-1 - z9-3 |

Always |

Below 1 Ω |

|

F23-12 - z11-5 |

Always |

Below 1 Ω |

|

F23-11 - z11-4 |

Always |

Below 1 Ω |

|

F23-10 - z11-3 |

Always |

Below 1 Ω |

|

F23-9 - z11-2 |

Always |

Below 1 Ω |

|

F23-8 - z11-1 |

Always |

Below 1 Ω |

|

F23-7 - z9-1 |

Always |

Below 1 Ω |

NOTICE:

As the spiral cable may break, do not rotate the spiral cable more than the specified amount.

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

PROCEDURE

1. REMOVE STEERING WHEEL ASSEMBLY

(a) Remove the steering wheel assembly (See page

).

2. REMOVE LOWER STEERING COLUMN COVER

3. REMOVE UPPER STEERIN ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL SPIRAL CABLE SUB-ASSEMBLY

(a) Attach the 3 claws to install the spiral cable.

CAUTION:

When replacing the spiral cable with a new one, remove the lock pin before ...

Other materials about Toyota 4Runner:

Steering Angle Sensor Zero Point Malfunction (C1290)

DESCRIPTION

The skid control ECU acquires steering angle sensor zero point every time the

ignition switch is turned to ON and the vehicle is driven at 40 km/h (25 mph) or

more for approximately 10 seconds. The ECU also stores the previous zero point.

If ...

Front Passenger Side Seat Belt Warning Light Malfunction

DESCRIPTION

When the ignition switch is ON, the occupant detection ECU sends a signal to

the airbag sensor assembly to indicate the state of the front seat inner belt assembly

RH and also whether the front passenger seat is occupied. The airbag sensor ass ...

0.0093