Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

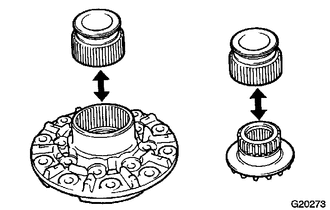

1. INSPECT REAR DIFFERENTIAL LOCK SLEEVE

(a) Install the sleeve to the differential case (LH) and check that it moves smoothly.

(b) Install the side gear to the sleeve and check that it moves smoothly.

|

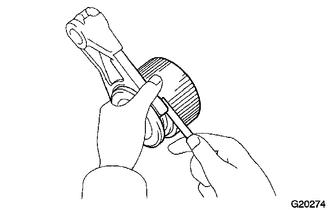

(c) Using a feeler gauge, measure the clearance between the shift fork and sleeve. Maximum clearance: 0.15 to 0.35 mm (0.0059 to 0.0138 in.) |

|

2. INSPECT DIFFERENTIAL PINION AND SIDE GEAR

(a) Check that there is no damage to the differential pinion or differential side gear.

If the differential pinion and/or differential side gear is damaged, replace the differential.

3. INSPECT DIFFERENTIAL CASE

(a) Check that the differential case is not damaged.

If the differential case is damaged, replace it.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. FIX REAR DIFFERENTIAL CARRIER ASSEMBLY IN PLACE

(a) Fix the rear differential carrier assembly to the overhaul attachment.

2. INSPECT REAR DRIVE PINION COMPANION FLANGE ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL DIFFERENTIAL CASE ASSEMBLY

(a) Install the rear differential side gear thrust washer to the rear differential

side gear.

(b) Install the rear differential pinio ...

Other materials about Toyota 4Runner:

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 STEREO JACK ADAPTER ASSEMBLY

(a) Attach the 2 claws to install the No. 1 stereo jack adapter assembly.

2. INSTALL LOWER CENTER INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY (w/o Climate

Control Seat System)

3. I ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE REAR PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

HINT:

Use the same procedure for all rear propeller shaft universal joint spider bearing.

(a) Place matchmarks on the flange yoke and sleeve yoke.

Text in Il ...

0.0276