Toyota 4Runner: No Answer-Back

DESCRIPTION

In some cases, the wireless door lock control functions are normal but the hazard warning light and/or wireless door lock buzzer answer-back function(s) does not operate. In such cases, hazard warning light and wireless door lock buzzer signal outputs from the main body ECU or certification ECU may be malfunctioning.

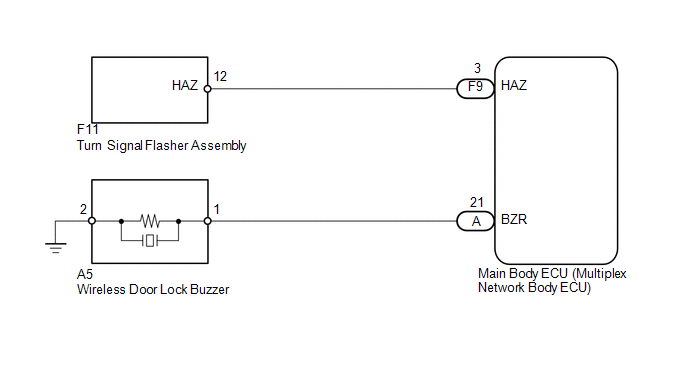

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Start troubleshooting after confirming that the customize status of the answer-back function has been switched on.

- Before performing the inspection, check that there are no problems related to the CAN communication system.

- Before replacing the certification ECU, refer to the engine immobiliser

system (w/ Smart Key System) (See page

.gif)

).

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (DOOR LOCK POSITION SWITCH) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Data List.

(e) Read the Data List according to the display on the Techstream.

Main Body|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

FR Door Lock Pos |

Front RH side door lock position switch signal / UNLOCK or LOCK |

UNLOCK: Front RH side door unlocked LOCK: Front RH side door locked |

- |

|

FL Door Lock Pos |

Front LH side door lock position switch signal / UNLOCK or LOCK |

UNLOCK: Front LH side door unlocked LOCK: Front LH side door locked |

- |

|

RR-Door Lock Pos SW |

Rear RH side door lock position switch signal / ON or OFF |

ON: Rear RH side door unlocked OFF: Rear RH side door locked |

- |

|

RL-Door Lock Pos SW |

Rear LH side door lock position switch signal / ON or OFF |

ON: Rear LH side door unlocked OFF: Rear LH side door locked |

- |

OK:

The Techstream should display as shown in the table according to door lock operation.

Result|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for Front RH Side) |

B |

|

NG (for Front LH Side) |

C |

|

NG (for Rear RH Side) |

D |

|

NG (for Rear LH Side) |

E |

| B | .gif) |

GO TO POWER DOOR LOCK CONTROL SYSTEM (Proceed to Only Passenger Door Lock/Unlock Functions do not Operate) |

| C | .gif) |

GO TO POWER DOOR LOCK CONTROL SYSTEM (Proceed to Only Driver Door Lock/Unlock Functions do not Operate) |

| D | .gif) |

GO TO POWER DOOR LOCK CONTROL SYSTEM (Proceed to Only Rear Door RH Lock/Unlock Functions do not Operate) |

| E | .gif) |

GO TO POWER DOOR LOCK CONTROL SYSTEM (Proceed to Only Rear Door LH Lock/Unlock Functions do not Operate) |

|

|

2. |

CHECK WIRELESS ANSWER-BACK OPERATION |

(a) Check the wireless answer-back operation by the wireless door lock control function.

Result|

Result |

Proceed to |

|---|---|

|

Only hazard warning light answer-back does not occur |

A |

|

Only wireless door lock buzzer answer-back does not occur |

B |

| B | .gif) |

GO TO STEP 6 |

|

|

3. |

CHECK HAZARD WARNING LIGHT OPERATION |

(a) Check that the hazard warning lights flash continuously when the hazard warning signal switch is pressed.

OK:

Hazard warning lights flash continuously.

| NG | .gif) |

GO TO LIGHTING SYSTEM |

|

|

4. |

PERFORM ACTIVE TEST USING TECHSTREAM (HAZARD WARNING LIGHT) |

(a) Operate the Techstream according to the steps on the display and select "Active

Test" (See page .gif) ).

).

Main Body

|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Hazard |

Turn signal flasher relay |

ON/OFF |

- |

OK:

The hazard warning lights can be turned on and off using the Techstream.

| OK | .gif) |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

|

5. |

CHECK HARNESS AND CONNECTOR (TURN SIGNAL FLASHER - MAIN BODY ECU) |

(a) Disconnect the F11 flasher connector.

(b) Disconnect the F9 ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F11-12 (HAZ) - F9-3 (HAZ) |

Always |

Below 1 Ω |

|

F11-12 (HAZ) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

6. |

PERFORM ACTIVE TEST USING TECHSTREAM (WIRELESS DOOR LOCK BUZZER) |

(a) Operate the Techstream according to the steps on the display and select "Active

Test" (See page .gif) ).

).

Main Body

|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Wireless Buzzer |

Wireless door lock buzzer |

ON/OFF |

- |

OK:

The wireless door lock buzzer can be turned on and off using the Techstream.

| NG | .gif) |

GO TO STEP 9 |

|

|

7. |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

(a) Temporarily replace the main body ECU with a new or normally functioning

one (See page .gif) ).

).

|

|

8. |

CHECK WIRELESS DOOR LOCK BUZZER OPERATION |

(a) Check that the wireless door lock buzzer sounds by operating the wireless door lock function.

OK:

Wireless door lock buzzer sounds.

| OK | .gif) |

END (MAIN BODY ECU IS DEFECTIVE) |

| NG | .gif) |

REPLACE CERTIFICATION ECU |

|

9. |

CHECK HARNESS AND CONNECTOR (WIRELESS DOOR LOCK BUZZER - MAIN BODY ECU) |

(a) Disconnect the A5 buzzer connector.

(b) Remove the main body ECU (See page .gif) ).

).

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A5-1 - A-21 (BZR) |

Always |

Below 1 Ω |

|

A5-2 - Body ground |

Always |

Below 1 Ω |

|

A5-1 - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

10. |

REPLACE WIRELESS DOOR LOCK BUZZER |

(a) Temporarily replace the wireless door lock buzzer with a new or normally

functioning one (See page .gif) ).

).

|

|

11. |

CHECK WIRELESS DOOR LOCK BUZZER OPERATION |

(a) Check that the wireless door lock buzzer sounds by operating the wireless door lock function.

OK:

Wireless door lock buzzer sounds.

| OK | .gif) |

END (WIRELESS DOOR LOCK BUZZER IS DEFECTIVE) |

| NG | .gif) |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

Wireless Door Lock Tuner Circuit Malfunction (B1242)

Wireless Door Lock Tuner Circuit Malfunction (B1242)

DESCRIPTION

The door lock receiver is used to receive electrical waves relating to the entry

functions of the smart key system (for Entry Function). The certification ECU decodes

the requested sm ...

Other materials about Toyota 4Runner:

Installation

INSTALLATION

PROCEDURE

1. INSTALL DOOR CONTROL RECEIVER

(a) Install the door control receiver with the bolt.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(b) Connect the connector.

2. INSTALL D ...

Main Owner’s Manual

Please note that this manual applies to all models and all equipment,

including options. Therefore, you may find some explanations for equipment not

installed on your vehicle.

All specifications provided in this manual are current at the time of

printin ...

0.0259

.gif)