Toyota 4Runner: Power Management Control ECU Communication Stop Mode

DESCRIPTION

|

Detection Item |

Symptom |

Trouble Area |

|---|---|---|

|

Power Management Control ECU Communication Stop Mode |

Either condition is met:

|

|

HINT:

For vehicles with a smart key system only.

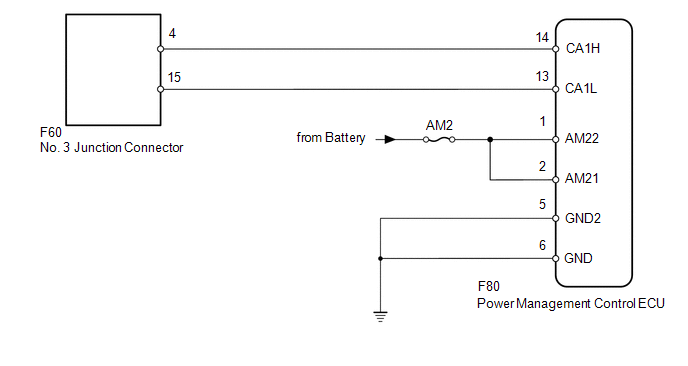

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

HINT:

Operating the ignition switch, any switches or any doors triggers related ECU and sensor communication with the CAN, which causes resistance variation.

PROCEDURE

|

1. |

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL |

(a) Disconnect the cable from the negative (-) battery terminal before measuring the resistances of the main wire and branch wire.

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to disable the SRS system.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

|

|

2. |

CHECK FOR OPEN IN CAN BUS WIRE (POWER MANAGEMENT CONTROL ECU BRANCH WIRE) |

|

(a) Disconnect the F80 power management control ECU connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

F80-14 (CA1H) - F80-13 (CA1L) |

Ignition switch off |

54 to 69 Ω |

|

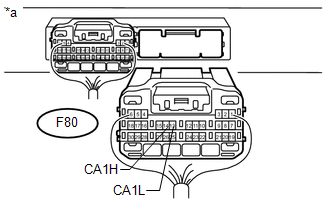

*a |

Rear view of wire harness connector (to Power Management Control ECU) |

| NG | .gif) |

REPAIR OR REPLACE POWER MANAGEMENT CONTROL ECU BRANCH WIRE OR CONNECTOR (CA1H, CA1L) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BATTERY AND BODY GROUND) |

|

(a) Connect the cable to the negative (-) battery terminal. NOTICE: When disconnecting the cable, some systems need to be initialized after

the cable is reconnected (See page |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F80-5 (GND2) - Body ground |

Always |

Below 1 Ω |

|

F80-6 (GND) - Body ground |

Always |

Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F80-1 (AM22) - Body ground |

Always |

11 to 14 V |

|

F80-2 (AM21) - Body ground |

Always |

11 to 14 V |

|

*a |

Rear view of wire harness connector (to Power Management Control ECU) |

| OK | .gif) |

REPLACE POWER MANAGEMENT CONTROL ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Main Body ECU Communication Stop Mode

Main Body ECU Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Main Body ECU Communication Stop Mode

Either condition is met:

"Main Bo ...

Combination Meter ECU Communication Stop Mode

Combination Meter ECU Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Combination Meter ECU Communication Stop Mode

Either condition is met:

" ...

Other materials about Toyota 4Runner:

Terminals Of Ecu

TERMINALS OF ECU

1. NAVIGATION RECEIVER ASSEMBLY (for 9 Speakers)

Terminal No. (Symbol)

Wiring Color

Terminal Description

Condition

Specified Condition

G5-2 (RL+) - G6-7 (GND)

...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR AXLE SHAFT LH

(a) Remove the rear axle shaft LH (See page

).

2. REMOVE REAR AXLE SHAFT RH

HINT:

Use the same procedure described for the LH side.

3. REMOVE PROPELLER SHAFT ASSEMBLY

(a) Remove the propeller shaft asse ...

0.0066

.gif)

.png)