Toyota 4Runner: Precaution

PRECAUTION

CAUTION:

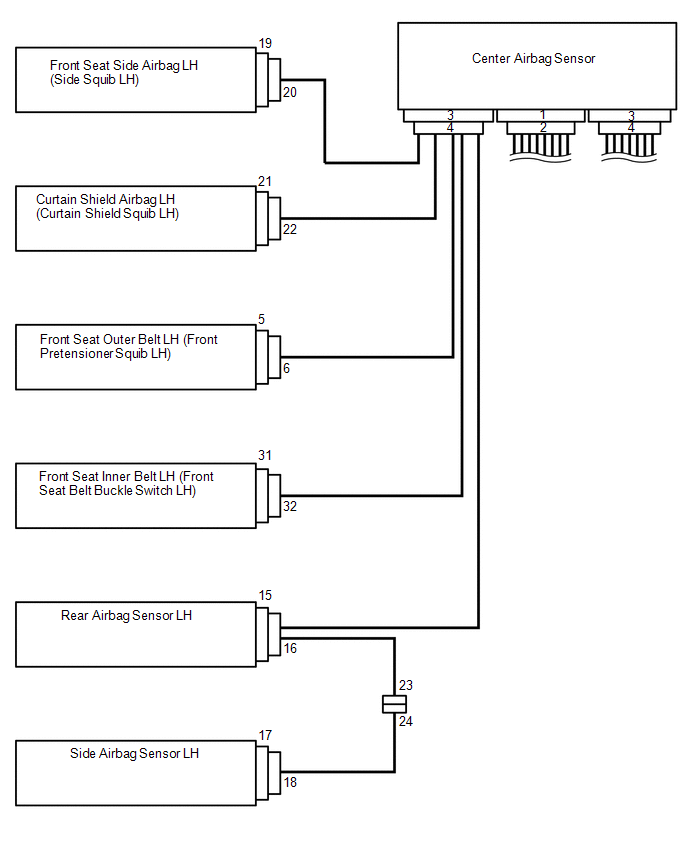

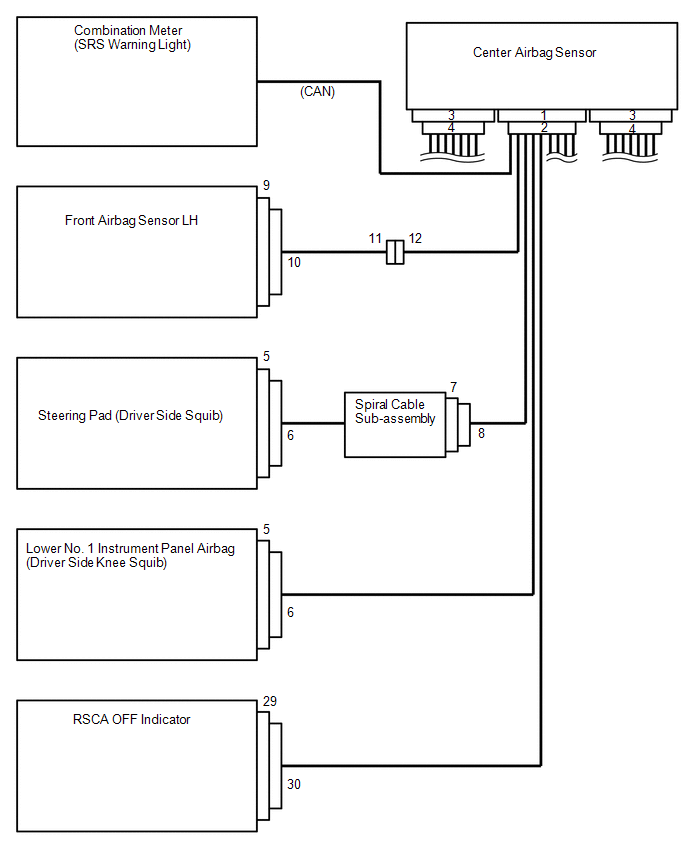

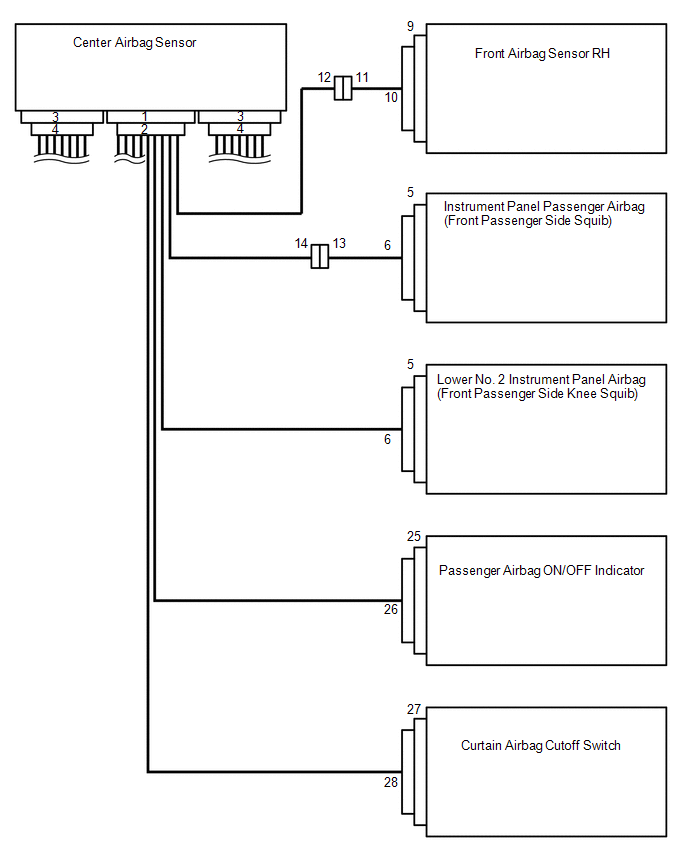

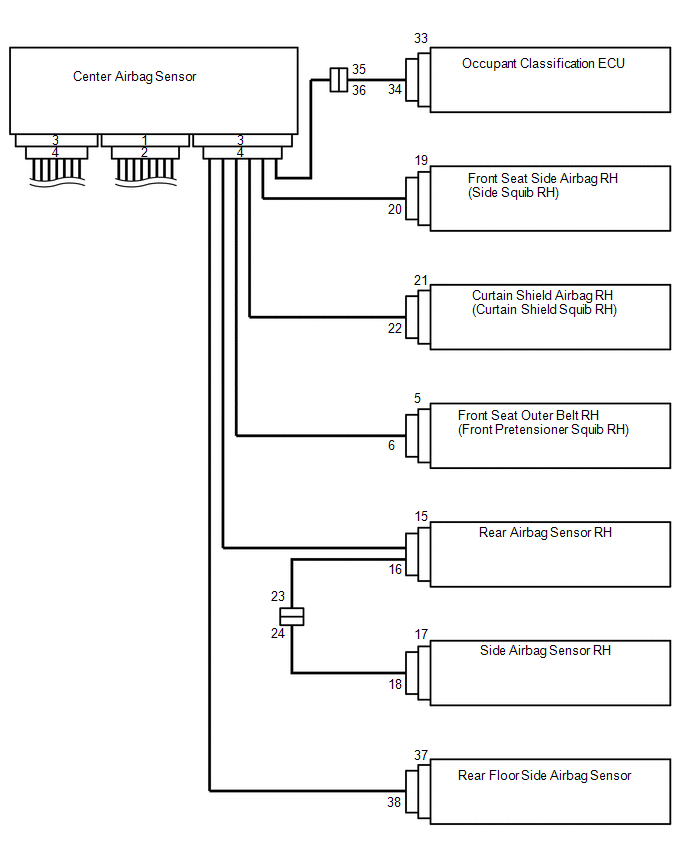

- This vehicle is equipped with a Supplemental Restraint System (SRS), which consists of a steering pad, instrument panel passenger airbag, curtain shield airbag, front seat side airbag, lower No. 1 instrument panel airbag, lower No. 2 instrument panel airbag, rear floor side airbag sensor, seat belt pretensioner, center airbag sensor, front airbag sensor, side airbag sensor, rear airbag sensor and occupant classification ECU. Failure to carry out service procedures in the correct sequence could cause SRS parts to unexpectedly deploy and possibly lead to serious injuries. Furthermore, if a mistake is made when servicing SRS parts, they may fail to operate when required. Before performing servicing (including installation/removal, inspection and replacement of parts), be sure to read the following precautions.

- Before starting work, wait at least 90 seconds after the ignition switch is turned off and after the cable is disconnected from the negative (-) battery terminal (SRS parts are equipped with a backup power source. If work is started within 90 seconds of turning the ignition switch off and disconnecting the cable from the negative (-) battery terminal, SRS parts may deploy).

- Do not expose SRS parts directly to hot air or flames.

- Be sure to perform initialization of the occupant classification ECU

under any of the following conditions. If initialization is not performed,

the SRS may not operate properly.

- The occupant classification ECU is replaced.

- Accessories (seatback tray, seat cover, etc.) are installed to the vehicle.

- The passenger seat is removed from the vehicle, and then reinstalled or replaced.

- The passenger airbag ON/OFF indicator light (OFF) comes on when the passenger seat is not occupied.

- The vehicle is brought to a workshop for repair due to an accident or collision.

NOTICE:

- Malfunction symptoms of SRS parts are difficult to confirm. DTCs are the most important source of information when troubleshooting. During troubleshooting, always confirm DTCs before disconnecting the cable from the negative (-) battery terminal.

- For minor collisions where SRS parts do not deploy, always inspect the SRS parts.

- Before performing repairs, remove the airbag sensors if any kind of impact is likely to occur to an airbag sensor during repairs.

- Never use SRS parts from another vehicle. When replacing SRS parts, replace them with new ones.

- Never disassemble or attempt to repair SRS parts.

- If an SRS part has been dropped, or if there are any cracks, dents or other defects in the case, bracket or connector, replace the SRS part with a new one.

- Use an ohmmeter/voltmeter with high impedance (10 kΩ/V minimum) for troubleshooting the electrical circuits.

- Information labels are attached to the periphery of SRS parts. Follow the cautions and instructions on the labels.

- After work on the SRS is completed, perform the SRS warning light check

(See page

.gif) ).

). - When the cable is disconnected from the negative (-) battery terminal, the memory settings of each system are cleared. Because of this, be sure to write down the settings of each system before starting work. When work is finished, reset the settings of each system as before. Never use a backup power supply from outside the vehicle to avoid clearing the memory in a system.

- If the vehicle is equipped with a mobile communication system, refer to the Precaution in the Introduction section.

HINT:

In the airbag system, the center airbag sensor, front airbag sensor LH and RH, side airbag sensor LH and RH, rear airbag sensor LH and RH, and rear floor side airbag sensor are collectively referred to as the airbag sensors.

1. HANDLING PRECAUTIONS FOR AIRBAG SENSORS

(a) Before starting the following operations, wait for at least 90 seconds after disconnecting the cable from the negative (-) battery terminal:

(1) Replacement of the airbag sensors.

(2) Adjustment of the front/rear doors of the vehicle equipped with side airbags and curtain shield airbags (fitting adjustment).

(b) When connecting or disconnecting the airbag sensor connectors, make sure that each sensor is installed in the vehicle.

(c) Do not use airbag sensors which have been dropped during operation or transportation.

(d) Do not disassemble the airbag sensors.

2. INSPECTION PROCEDURE FOR VEHICLE INVOLVED IN ACCIDENT

(a) When the airbag has not deployed, confirm the DTCs by checking the SRS warning light. If there is any malfunction in the SRS airbag system, perform troubleshooting.

(b) When any of the airbags have deployed due to the collision, be sure to replace all sensors in the damaged areas and center airbag sensor assembly.

3. SRS CONNECTORS

(a) SRS connectors are located as shown in the following illustration.

|

Item |

Application |

|---|---|

|

Terminal Twin-lock Mechanism |

Connectors 8, 11, 12, 13, 14, 23, 24, 35, 36 |

|

Activation Prevention Mechanism |

Connectors 2, 4, 7, 13, 19, 21 |

|

Half Connection Prevention Mechanism |

Connectors 8, 12, 13, 19, 21, 23, 36 |

|

Connector Position Assurance Mechanism |

Connectors 10, 16, 18, 38 |

|

Connector Lock Mechanism (1) |

Connectors 6 |

|

Connector Lock Mechanism (2) |

Connectors 2, 4 |

|

Improper Connection Prevention Lock Mechanism |

Connectors 1, 3 |

(b) All connectors in the SRS, except the seat position sensor connector, are colored yellow to distinguish them from other connectors. These connectors have special functions and are specially designed for the SRS. All SRS connectors use durable gold-plated terminals which are placed in the locations shown below to ensure high reliability.

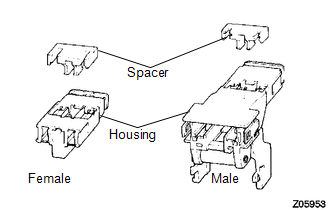

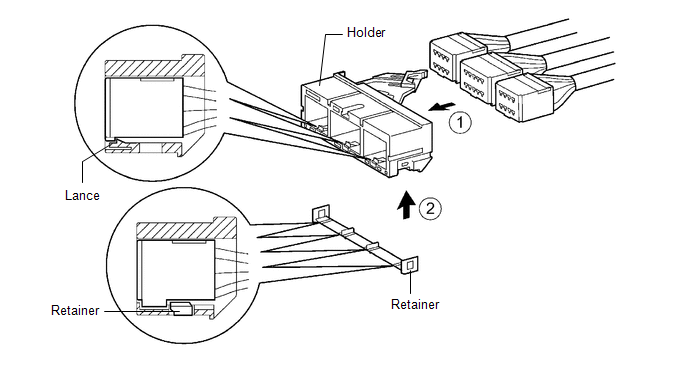

(1) Terminal twin-lock mechanism:

All connectors with a terminal twin-lock mechanism have a two-piece component consisting of a housing and spacer. This design enables the terminal to be locked securely by two locking devices (the retainer and the lance) to prevent terminals from coming out.

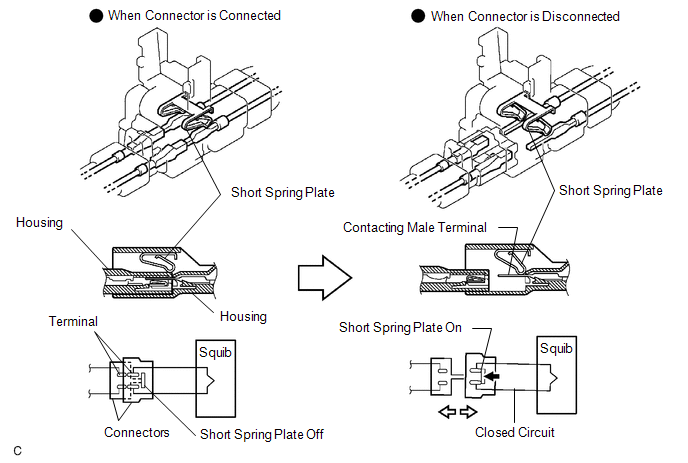

(2) Activation prevention mechanism:

All connectors with an activation prevention mechanism contain a short spring plate. When these connectors are disconnected, the short spring plate creates a short circuit by automatically connecting the positive (+) and negative (-) terminals of the squib.

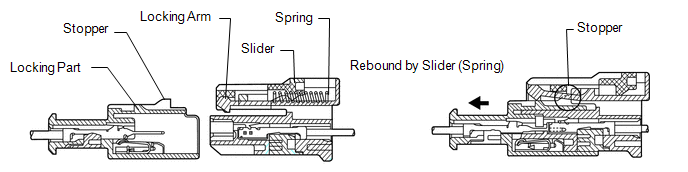

(3) Half connection prevention mechanism:

If the connector is not completely connected, the connector is disconnected by the force of the spring so that no continuity exists.

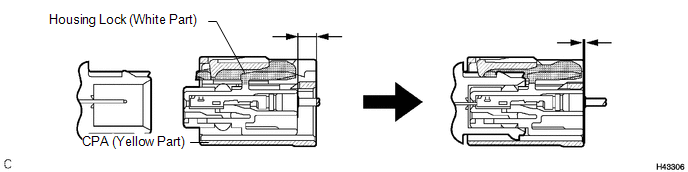

(4) Connector position assurance mechanism:

The CPA (yellow part) slides only when the housing lock (white part) is completely engaged, which completes the connector engagement.

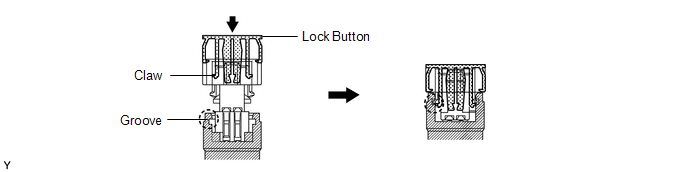

(5) Connector lock mechanism (1):

Locking the connector lock button connects the connector securely.

(6) Connector lock mechanism (2):

Both the primary lock with holder lances and the secondary lock with retainer prevent the connectors from becoming disconnected.

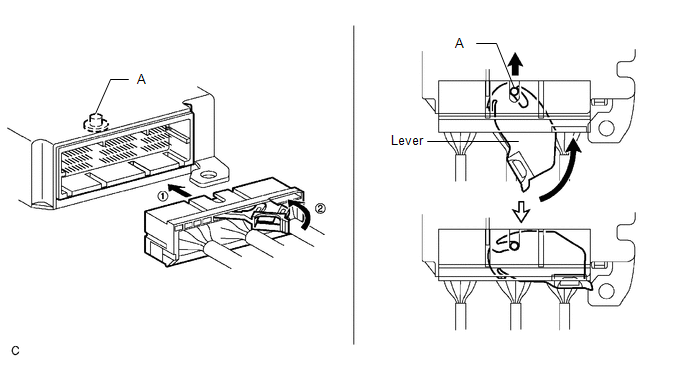

(7) Improper connection prevention lock mechanism:

When connecting the holder, the lever is pushed into the lock position by rotating around the A axis to lock the holder securely.

Airbag System

Airbag System

...

Parts Location

Parts Location

PARTS LOCATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Other materials about Toyota 4Runner:

Lost Communication with A/C ECU (U0164)

DESCRIPTION

DTC Code

DTC Detection Condition

Trouble Area

U0164

There is no communication from the air conditioning amplifier assembly.

Power source or inside air conditioning ...

Steering Angle Sensor Unusual Bank Angle Detected (C1440)

DESCRIPTION

If the skid control ECU determines that the vehicle is being driven at a steep

bank angle, the skid control ECU stores DTC C1440 while VSC operation is temporarily

disabled.

It is not a malfunction if the system and sensor circuits are normal ...

0.0066