Toyota 4Runner: Torque Converter Clutch And Drive Plate

Inspection

INSPECTION

PROCEDURE

1. INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY

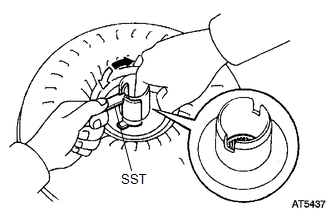

(a) Inspect the 1-way clutch.

(1) Install SST to the inner race of the 1-way clutch.

SST: 09350-32014

09351-32020

(2) Press on the serrations of the starter with a finger and rotate it.

Check if it rotates smoothly when turned clockwise and locks when turned counterclockwise.

Text in Illustration

.png) |

Free |

.png) |

Lock |

If the results are not as specified, clean the converter and recheck the 1-way clutch. If the results still are not as specified, replace the torque converter clutch assembly.

|

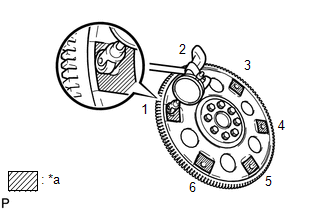

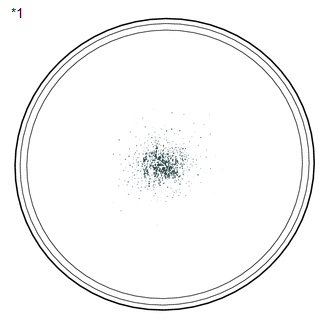

(b) Determine the condition of the torque converter clutch. Text in Illustration

(1) Check that the following conditions are met:

If the results are not as specified, replace the torque converter clutch assembly. HINT: The sample illustration shows approximately 0.025 liters (0.026 US qts, 0.022 Imp. qts) of ATF taken from a removed torque converter clutch. |

|

(c) Replace the ATF in the torque converter clutch.

(1) AT If the ATF is discolored and/or has a foul odor, stir the ATF in the torque converter clutch thoroughly and drain the ATF with the torque converter facing upward.

|

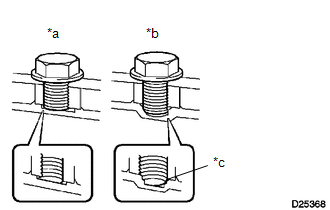

(d) Prevent deformation of the torque converter clutch and damage to the oil pump gear. Text in Illustration

(1) When any marks due to interference are found on the end of the bolt for the torque converter clutch and on the bottom of the bolt hole, replace the bolt and torque converter clutch. (2) All of the bolts should be the same length. (3) Make sure no spring washers are missing. |

|

2. INSPECT DRIVE PLATE

(a) Check the drive plate for damage.

|

(b) Set up a dial indicator and measure the runout of the 6 portions around the torque converter clutch contact surfaces. Maximum runout: 0.30 mm (0.0118 in.) Text in Illustration

If the runout is more than the maximum, or the drive plate is damaged,

replace the drive plate (See page |

|

Speed Sensor

Speed Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE SPEED SENSOR NT

(a) Disconnect the sensor connector.

(b) Remove the bolt and sensor.

(c) Remove the O-ring from ...

Transmission Control Cable

Transmission Control Cable

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE CONSOLE BOX ASSEMBLY

(a) Remove the console box assembly (See page

).

2. REMOVE TRANSMISSION CONTROL CABLE ASSEM ...

Other materials about Toyota 4Runner:

Transmission Control Switch Circuit

DESCRIPTION

After moving the shift lever to S, it is possible to switch the shift range between

"1" (S1 range) and "5" (S5 range) using the transmission control switch.

Shifting to "+" once raises the shift range by one, and s ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT REAR DOOR LOCK ASSEMBLY LH

(a) Check the door lock motor operation.

(1) Apply battery voltage to the door lock motor and check the operation

of the door lock motor.

OK:

Measurement Cond ...

0.0199

.gif) ).

).