Toyota 4Runner: Speed Sensor

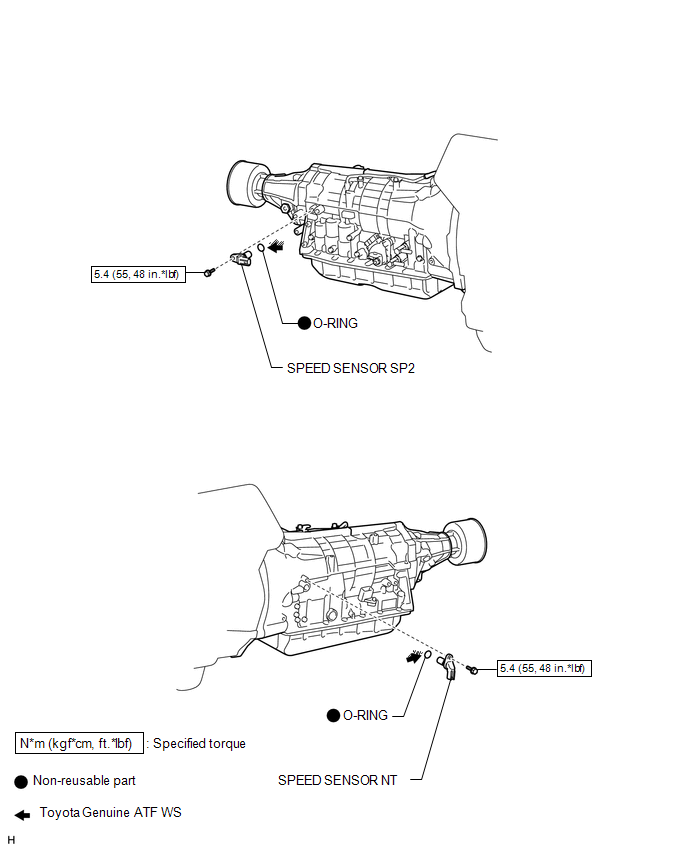

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

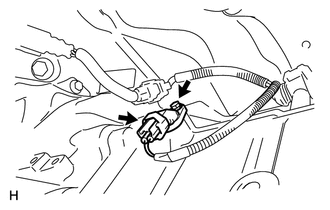

1. REMOVE SPEED SENSOR NT

(a) Disconnect the sensor connector.

(b) Remove the bolt and sensor.

(c) Remove the O-ring from the sensor.

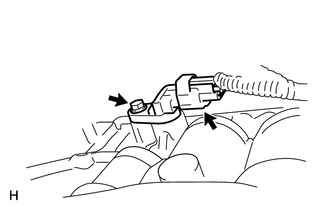

2. REMOVE SPEED SENSOR SP2

(a) Disconnect the sensor connector.

(b) Remove the bolt and sensor.

(c) Remove the O-ring from the sensor.

Inspection

INSPECTION

PROCEDURE

1. INSPECT SPEED SENSOR NT AND SP2

.png)

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

20°C (68°F) |

560 to 680 Ω |

|

*a |

Component without harness connected (Speed Sensor) |

If the result is not as specified, replace the sensor.

Installation

INSTALLATION

PROCEDURE

1. INSTALL SPEED SENSOR SP2

(a) Coat a new O-ring with ATF and install it to the sensor.

(b) Install the sensor with the bolt.

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

(c) Connect the sensor connector.

2. INSTALL SPEED SENSOR NT

(a) Coat a new O-ring with ATF and install it to the sensor.

(b) Install the sensor with the bolt.

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

(c) Connect the sensor connector.

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL SHIFT LOCK CONTROL ECU SUB-ASSEMBLY

(a) Attach the 3 claws to install the shift lock control ECU to the transmission

floor shift.

(b) Connect the shift lock solen ...

Torque Converter Clutch And Drive Plate

Torque Converter Clutch And Drive Plate

Inspection

INSPECTION

PROCEDURE

1. INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY

(a) Inspect the 1-way clutch.

(1) Install SST to the inner race of the 1-way clutch.

SST: 09350-32014

09351-32020 ...

Other materials about Toyota 4Runner:

Installation

INSTALLATION

PROCEDURE

1. INSTALL OUTER BACK DOOR GLASS WEATHERSTRIP ASSEMBLY

(a) Attach the 8 claws to install the outer back door glass weatherstrip.

2. INSTALL BACK DOOR GLASS

3. INSTALL BACK DOOR GLASS RUN

4. INSTALL NO. 1 BACK WINDOW WIPER MOT ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) Install the spring and check ball body.

(b) Insert the pin of the manual valve into the hole of the manual valve

lever.

Text in Illustration

*1

...

0.007