Toyota 4Runner: Traction Off Switch

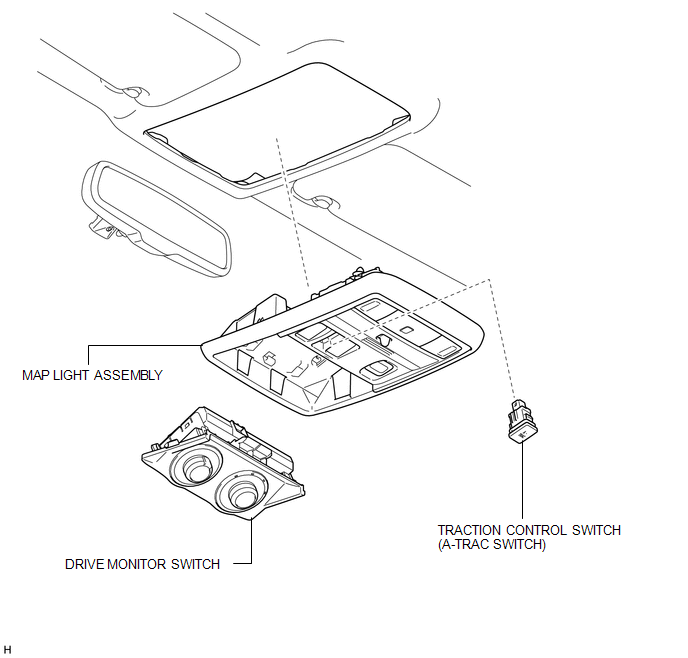

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

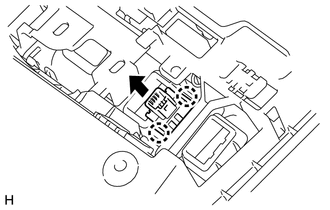

1. REMOVE DRIVE MONITOR SWITCH

.gif)

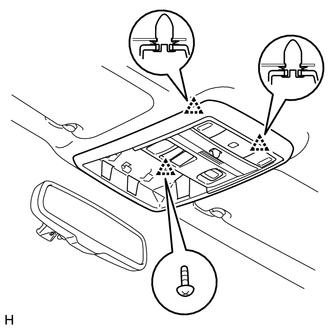

2. REMOVE MAP LIGHT ASSEMBLY

|

(a) Remove the screws. |

|

(b) Detach the 2 clips and remove the map light assembly.

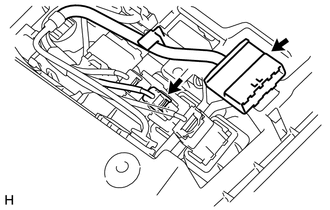

3. REMOVE TRACTION CONTROL SWITCH (A-TRAC SWITCH)

|

(a) Disconnect the 2 connectors. |

|

|

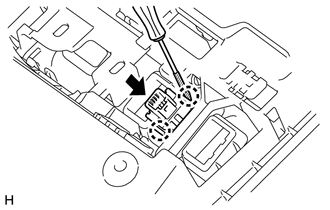

(b) Using a screwdriver, detach the 2 claws and remove the traction control switch (A-TRAC switch) from the map light assembly. HINT: Tape the screwdriver tip before use. |

|

Inspection

INSPECTION

PROCEDURE

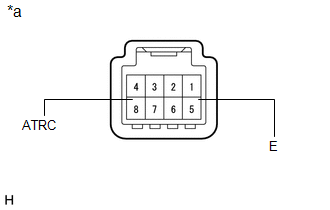

1. INSPECT TRACTION CONTROL SWITCH (A-TRAC SWITCH)

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the traction control switch (A-TRAC switch). |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRACTION CONTROL SWITCH (A-TRAC SWITCH)

|

(a) Attach the 2 claws to install the traction control switch (A-TRAC switch) to the map light assembly. |

|

(b) Connect the 2 connectors.

2. INSTALL MAP LIGHT ASSEMBLY

(a) Attach the 2 clips to install the map light assembly.

(b) Install the screws.

3. INSTALL DRIVE MONITOR SWITCH

.gif)

Steering Angle Sensor

Steering Angle Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 sec ...

Other materials about Toyota 4Runner:

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR DIFFERENTIAL CARRIER ASSEMBLY

(a) Install a new gasket and the differential carrier assembly with the 10 nuts

and 10 washers.

Torque:

52 N·m {530 kgf·cm, 38 ft·lbf}

2. INSTALL REAR AXLE SHAFT LH

(a) Install t ...

PTC Heater Circuit

DESCRIPTION

PTC heater relays are closed in accordance with signals from the air conditioning

amplifier assembly and power is supplied to the quick heater assembly installed

on the radiator heater unit.

WIRING DIAGRAM

PROCEDURE

1.

...

0.0259