Toyota 4Runner: Air Conditioning Compressor Magnetic Clutch Circuit

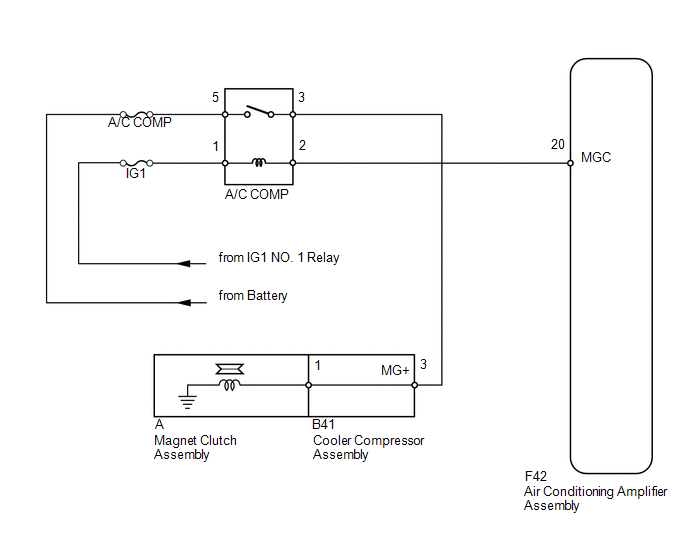

DESCRIPTION

When the air conditioning amplifier assembly is turned on, a magnet clutch assembly signal is sent from the MGC terminal of the air conditioning amplifier assembly. Then, the A/C COMP relay turns on to operate the magnet clutch assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

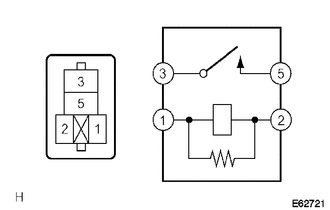

INSPECT MAGNET CLUTCH RELAY (A/C COMP) |

|

(a) Remove the A/C COMP relay from the engine room No. 1 relay block, junction block. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 - 5 |

Battery voltage is not applied to terminals 1 and 2 |

10 kΩ or higher |

|

Battery voltage is applied to terminals 1 and 2 |

Below 1 Ω |

| NG | .gif) |

REPLACE MAGNET CLUTCH RELAY (A/C COMP) |

|

|

2. |

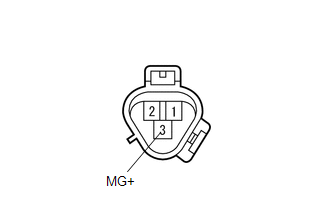

INSPECT COOLER COMPRESSOR ASSEMBLY |

|

(a) Remove the cooler compressor assembly (See page

|

|

(b) Disconnect the A magnet clutch connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (MG+) - A-1 |

Always |

Below 1 Ω |

|

3 (MG+) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPLACE COOLER COMPRESSOR ASSEMBLY |

|

|

3. |

INSPECT MAGNETIC CLUTCH ASSEMBLY |

|

(a) Reconnect the A magnet clutch connector. |

|

(b) Apply battery voltage to the magnet clutch assembly and check the operation of the magnet clutch assembly.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → Terminal 3 (MG+) Battery negative (-) → Body ground |

Magnet clutch assembly operating sound can be heard, and magnetic clutch hub and rotor lock. |

| NG | .gif) |

REPLACE MAGNET CLUTCH ASSEMBLY |

|

|

4. |

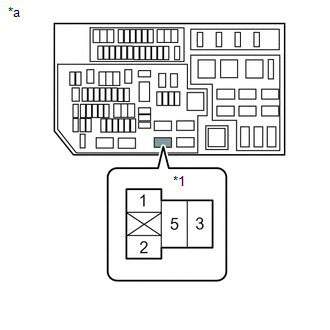

CHECK HARNESS AND CONNECTOR (ENGINE ROOM NO. 1 RELAY BLOCK, JUNCTION BLOCK - BATTERY) |

|

(a) Remove the A/C COMP relay from the engine room No. 1 relay block, junction block. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A/C COMP relay terminal 1 - Body ground |

Ignition switch ON |

11 to 14 V |

|

A/C COMP relay terminal 5 - Body ground |

Always |

11 to 14 V |

|

*1 |

A/C COMP Relay |

|

*a |

Component without relay installed (Engine Room No. 1 Relay Block, Junction Block) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

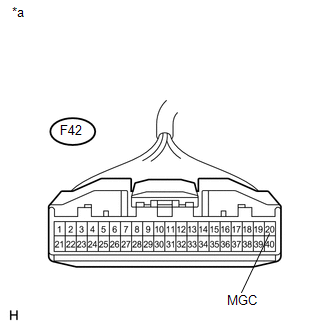

CHECK HARNESS AND CONNECTOR (AIR CONDITIONING AMPLIFIER - BATTERY) |

(a) Disconnect the F42 amplifier connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

F42-20 (MGC) - Body ground |

Ignition switch off |

Below 1 V |

|

F42-20 (MGC) - Body ground |

Ignition switch ON |

11 to 14 V |

|

*a |

Front view of wire harness connector (to Air Conditioning Amplifier Assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK HARNESS AND CONNECTOR (ENGINE ROOM NO. 1 RELAY BLOCK, JUNCTION BLOCK - COOLER COMPRESSOR) |

(a) Remove the A/C COMP relay from the engine room No. 1 relay block, junction block.

(b) Disconnect the B41 compressor connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A/C COMP relay terminal 3 - B41-3 (MG+) |

Always |

Below 1 Ω |

|

B41-3 (MG+) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Blower Motor Circuit

Blower Motor Circuit

DESCRIPTION

The blower with fan motor sub-assembly operates according to signals from the

air conditioning amplifier assembly. The blower with fan motor sub-assembly speed

signals are transmitt ...

Generator Signal Circuit

Generator Signal Circuit

DESCRIPTION

When the engine is started, the generator assembly turns on and a voltage pulse

signal is generated.

This signal is used by the air conditioning amplifier assembly.

The signal express ...

Other materials about Toyota 4Runner:

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. TEMPORARILY INSTALL FRONT DISC BRAKE BLEEDER PLUG

(a) Temporarily install the front dis ...

If the vehicle becomes stuck

Carry out the following procedures if the tires spin or the vehicle

becomes stuck in mud, dirt or snow:

Stop the engine. Set the parking

brake and shift the shift lever to P.

Remove the mud, snow or sand

from around the stuck tire.

Place wood, ston ...

0.0265

.gif)

.gif) ).

).