Toyota 4Runner: Air Conditioning Pressure Sensor

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT NO. 1 PRESSURE SWITCH

|

(a) Connect a manifold gauge set. |

|

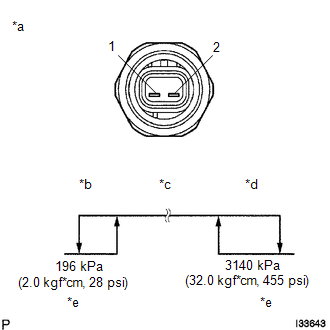

(b) Connect the positive (+) lead from the ohmmeter to terminal 1 and the negative (-) lead to terminal 2.

(c) Measure the resistance between terminals when refrigerant pressure is charged, as shown in the illustration.

If operation is not as specified, replace the pressure switch.

Text in Illustration|

*a |

Component without harness connected (No. 1 Pressure Switch) |

|

*b |

Low Pressure Side |

|

*c |

On (Below 1.0 Ω) |

|

*d |

High Pressure Side |

|

*e |

Off (10 kΩ or higher) |

Installation

INSTALLATION

PROCEDURE

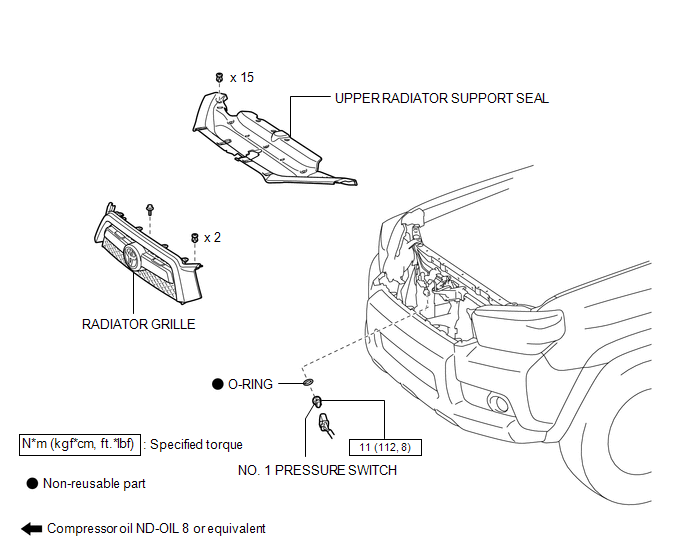

1. INSTALL NO. 1 PRESSURE SWITCH

(a) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the No. 1 pressure switch.

Compressor oil:

ND-OIL 8 or equivalent

(b) Install the O-ring to the No. 1 pressure switch.

(c) Install the No. 1 pressure switch.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

(d) Connect the connector.

2. CHARGE REFRIGERANT

.gif)

3. WARM UP ENGINE

.gif)

4. CHECK FOR REFRIGERANT GAS LEAK

.gif)

5. INSTALL RADIATOR GRILLE

(a) Install the radiator grille (See page .gif) ).

).

6. INSTALL UPPER RADIATOR SUPPORT SEAL

.gif)

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER RADIATOR SUPPORT SEAL

.gif)

2. REMOVE RADIATOR GRILLE

(a) Remove the radiator grille (See page .gif) ).

).

3. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

.gif)

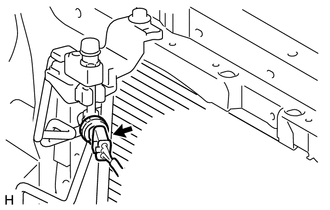

4. REMOVE NO. 1 PRESSURE SWITCH

(a) Disconnect the connector.

(b) Remove the No. 1 pressure switch.

(c) Remove the O-ring from the No. 1 pressure switch.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering them.

Air Conditioning Panel

Air Conditioning Panel

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL HEATER CONTROL ASSEMBLY

(a) Attach the 4 clips to install the heater control assembly.

...

Other materials about Toyota 4Runner:

Position Initialization Incomplete (B2343)

DESCRIPTION

This DTC is stored when the sliding roof drive gear sub-assembly (sliding roof

ECU) has not been initialized.

DTC Code

DTC Detection Condition

Trouble Area

B2343

The sliding roof driv ...

Rear Occupant Classification Sensor RH Circuit Malfunction (B1783)

DESCRIPTION

The rear occupant classification sensor RH circuit consists of the occupant classification

ECU and rear occupant classification sensor RH.

DTC B1783 is stored when a malfunction is detected in the rear occupant classification

sensor RH circui ...

0.0268