Toyota 4Runner: Automatic Disconnecting Differential Actuator

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

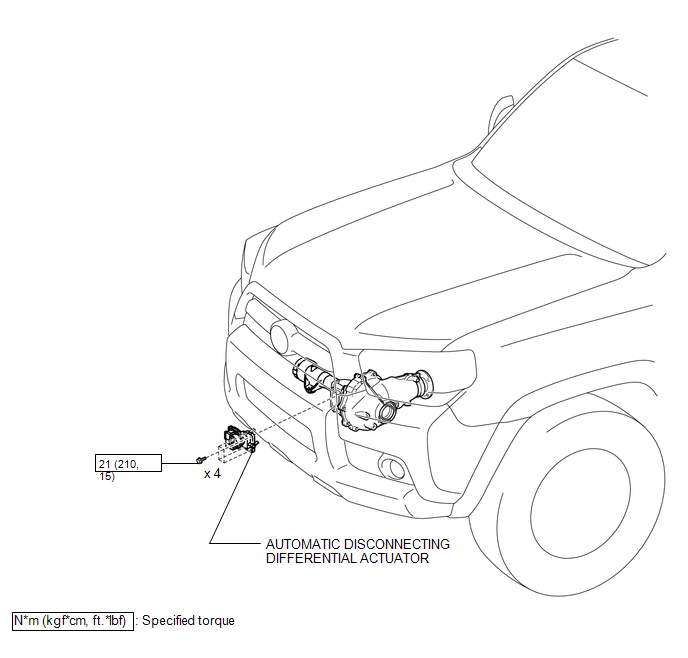

1. INSTALL AUTOMATIC DISCONNECTING DIFFERENTIAL ACTUATOR

(a) Remove any old FIPG material.

NOTICE:

Be careful not to drop oil on the contact surfaces of the actuator and clutch case.

(b) Using gasoline or alcohol, wipe off any residual FIPG material on the contact surfaces.

|

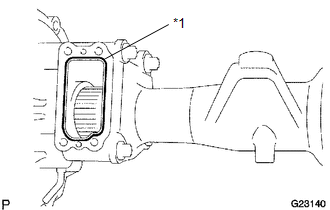

(c) Apply seal packing to the differential tube as shown in the illustration. Seal packing: Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Text in Illustration

HINT: Install the actuator within 10 minutes of applying seal packing. |

|

(d) Clean the threads of the 4 bolts and retainer bolt holes with toluene or trichloroethylene.

(e) Apply adhesive to 2 or 3 threads at the tip of the bolts.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

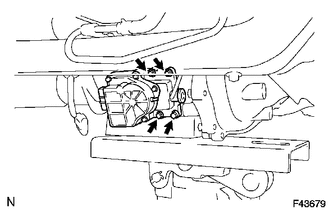

(f) Install the actuator to the differential tube with the 4 bolts.

Torque:

21 N·m {210 kgf·cm, 15 ft·lbf}

(g) Connect the actuator hose and connector.

(h) Support the differential with a jack.

(i) Install the 2 front mounting bolts and 2 nuts.

Torque:

137 N·m {1400 kgf·cm, 101 ft·lbf}

(j) Install the No. 1 differential mounting nut.

Torque:

87 N·m {887 kgf·cm, 64 ft·lbf}

(k) Install the differential breather tube bracket with the bolt.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

2. ADD DIFFERENTIAL OIL

(a) Add differential oil (See page .gif) ).

).

3. CHECK FOR DIFFERENTIAL OIL LEAKAGE

4. INSTALL REAR ENGINE UNDER COVER ASSEMBLY

.gif)

5. INSTALL NO. 1 ENGINE UNDER COVER

.gif)

6. INSTALL FRONT SIDE MEMBER TO FRONT SUSPENSION CROSSMEMBER BRACE

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT SIDE MEMBER TO FRONT SUSPENSION CROSSMEMBER BRACE

2. REMOVE NO. 1 ENGINE UNDER COVER

.gif)

3. REMOVE REAR ENGINE UNDER COVER ASSEMBLY

.gif)

4. DRAIN DIFFERENTIAL OIL

5. REMOVE AUTOMATIC DISCONNECTING DIFFERENTIAL ACTUATOR

|

(a) Remove the bolt and disconnect the differential breather tube bracket. |

|

(b) Support the differential with a jack.

(c) Remove No. 1 differential mounting nut.

(d) Remove the 2 mounting bolts and nut.

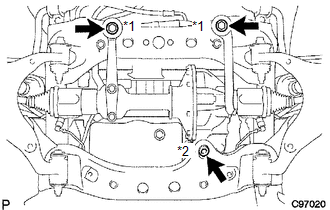

Text in Illustration|

*1 |

Mounting Bolt |

|

*2 |

Mounting Nut |

(e) Disconnect the actuator hose and connector.

(f) Lower the jack.

|

(g) Remove the 4 bolts and actuator. |

|

Axle System

Axle System

...

Other materials about Toyota 4Runner:

Short to GND in Hall Effect Sensor Power Circuit (31)

DESCRIPTION

When there is a short to GND in the side auto step motor hall sensor power circuit,

the side auto step controller ECU assembly does not operate the automatic running

board.

DTC No.

Detection Condition

Trouble ...

Rear Power Outlet Socket

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE POWER OUTLET SOCKET BEZEL (w/o Smart Key System)

(a) Put protective tape around the power outlet socket bezel.

Text in Illustration

*1

...

0.0094