Toyota 4Runner: Disassembly

DISASSEMBLY

PROCEDURE

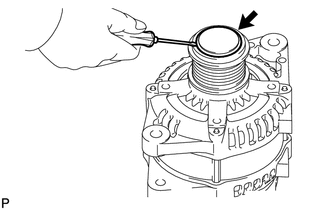

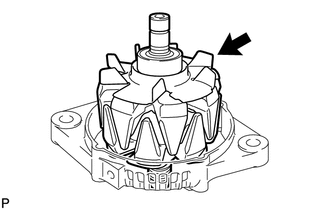

1. REMOVE GENERATOR PULLEY CAP

|

(a) Using a screwdriver, remove the generator pulley cap. |

|

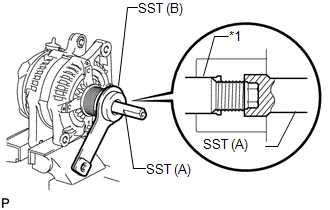

2. REMOVE GENERATOR WITH CLUTCH PULLEY

(a) Mount the generator in a vise between aluminum plates.

|

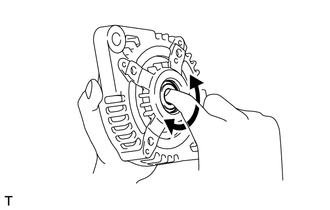

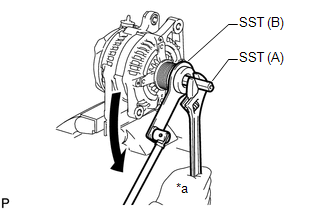

(b) Install SST (A) and SST (B) to the generator with clutch pulley as shown in the illustration. SST: 09820-63021 Text in Illustration

NOTICE: Securely attach SST to the generator with clutch pulley and generator rotor shaft. |

|

(c) Use a wrench to hold SST (A) and turn SST (B) counterclockwise to loosen the generator with clutch pulley.

Text in Illustration

Text in Illustration

|

*a |

Hold |

.png) |

Turn |

NOTICE:

Be careful as the generator with clutch pulley or generator rotor shaft may be damaged if the position of SST is not securely maintained while performing this operation.

(d) Remove SST from the generator.

(e) Remove the generator with clutch pulley from the rotor shaft.

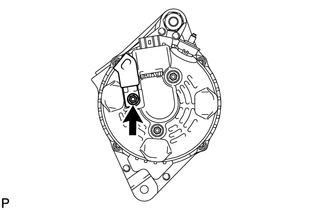

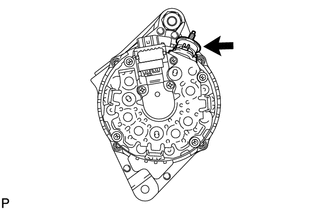

3. REMOVE GENERATOR REAR END COVER

|

(a) Remove the nut and cord clip. |

|

|

(b) Remove the 3 nuts and generator rear end cover. |

|

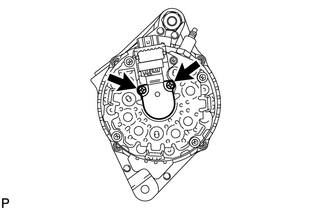

4. REMOVE TERMINAL INSULATOR

|

(a) Remove the terminal insulator from the generator coil. |

|

5. REMOVE GENERATOR BRUSH HOLDER ASSEMBLY

|

(a) Remove the 2 screws and brush holder from the generator coil. |

|

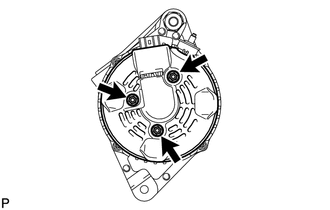

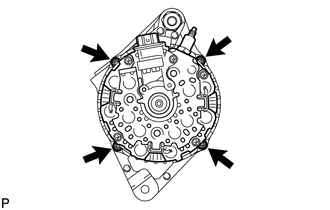

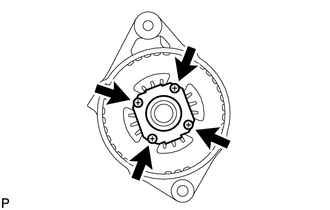

6. REMOVE GENERATOR COIL ASSEMBLY

|

(a) Remove the 4 bolts. |

|

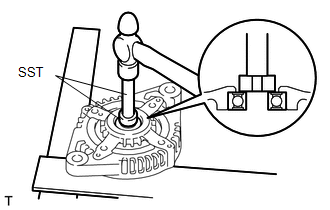

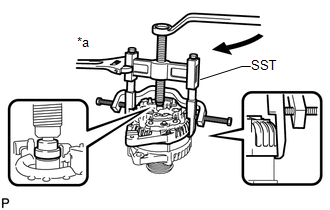

(b) Using SST, remove the generator coil assembly.

SST: 09950-40011

09951-04020

09952-04010

09953-04020

09954-04010

09955-04071

09957-04010

09958-04011

Text in Illustration|

*a |

Hold |

.png) |

Turn |

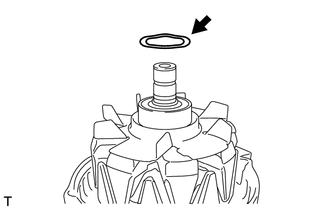

7. REMOVE GENERATOR ROTOR ASSEMBLY

|

(a) Remove the generator washer. |

|

|

(b) Remove the generator rotor assembly. |

|

8. INSPECT GENERATOR DRIVE END FRAME BEARING

|

(a) Check that the drive end frame bearing is not rough or worn. If necessary, replace the generator drive end frame bearing. |

|

9. REMOVE GENERATOR DRIVE END FRAME BEARING

|

(a) Remove the 4 screws and retainer plate from the drive end frame. |

|

|

(b) Using SST and a hammer, tap out the drive end frame bearing from the drive end frame. SST: 09950-60010 09951-00250 SST: 09950-70010 09951-07100 |

|

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. DI ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT GENERATOR WITH CLUTCH PULLEY

(a) Hold the center of the generator with clutch pulley and check that the outer

ring turns counterclockwise and does not turn clockwi ...

Other materials about Toyota 4Runner:

Extension Housing Rear Oil Seal

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE PROPELLER SHAFT ASSEMBLY

(a) Remove the propeller shaft (See page ).

2. REMOVE AUTOMATIC TRANSMISSION EXTENSION HOUSING OIL SEAL

(a) Using SST, remove the oil seal ...

Unable to Lock Steering Wheel

DESCRIPTION

The steering lock ECU sends an unlock position signal to the power management

control ECU. Upon receiving the signal, the power management control ECU permits

an engine start. This prevents the engine from being started with the steering locke ...

0.0138