Toyota 4Runner: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. DISCONNECT CABLE FROM POSITIVE BATTERY TERMINAL

3. REMOVE BATTERY CLAMP

|

(a) Loosen the 2 nuts and remove the battery clamp. |

|

4. REMOVE BATTERY

5. REMOVE BATTERY TRAY

6. REMOVE V-BANK COVER

.gif)

7. REMOVE FAN AND GENERATOR V BELT

.gif)

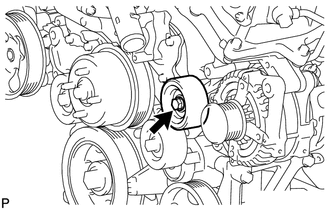

8. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

|

(a) for Integrated Type: Remove the bolt and No. 2 idler pulley. |

|

(b) for Separate Type:

Remove the bolt, No. 2 idler pulley cover plate, No. 2 idler pulley and idler pulley cover plate.

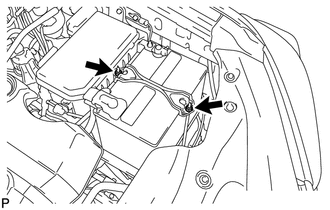

9. REMOVE WIRING HARNESS CLAMP BRACKET

|

(a) Detach the clamp. |

|

(b) Remove the bolt and wiring harness clamp bracket.

10. REMOVE NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

.gif)

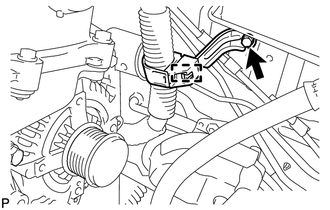

11. REMOVE GENERATOR ASSEMBLY

|

(a) Open the terminal cap. |

|

(b) Remove the nut and disconnect the wire harness from terminal B.

(c) Disconnect the generator connector from the generator assembly.

|

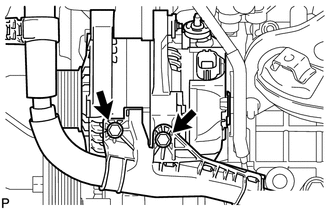

(d) Remove the 2 bolts and disconnect the wire harness. |

|

|

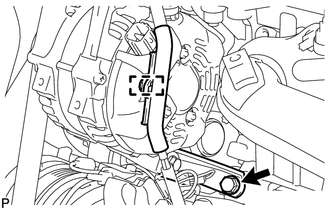

(e) Disconnect the wire harness clamp. |

|

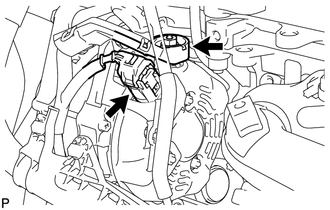

(f) Remove the bolt and disconnect the generator bracket.

|

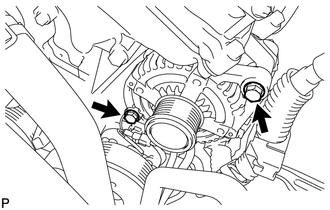

(g) Remove the 2 bolts and generator assembly. |

|

|

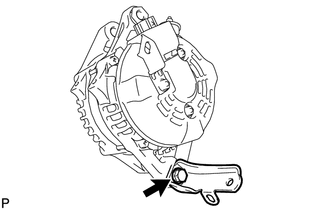

(h) Remove the bolt and generator bracket. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE GENERATOR PULLEY CAP

(a) Using a screwdriver, remove the generator pulley cap.

2. REMOVE GENERATOR WITH CLUTCH ...

Other materials about Toyota 4Runner:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMOVE LOWER FRONT BUMPER COVER (w/ KDSS)

3. REMOVE NO. 1 ENGINE ...

0.0256