Toyota 4Runner: ECU Power Source Circuit

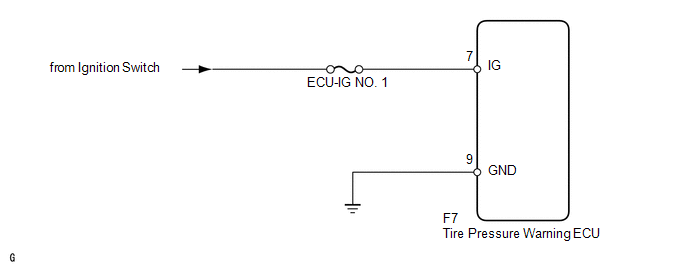

DESCRIPTION

This is the power source for the tire pressure warning ECU.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the tire pressure warning ECU, read the IDs stored in the old ECU using the Techstream and write them down before removal.

- It is necessary to perform registration of the transmitter IDs into

the tire pressure warning ECU after the ECU and/or the tire pressure warning

valve and transmitter has been replaced (See page

.gif) ).

). - Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (ECU - BATTERY) |

|

(a) Disconnect the F7 ECU connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

F7-7 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

Ignition switch off |

Below 1 V |

|

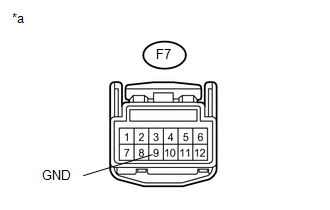

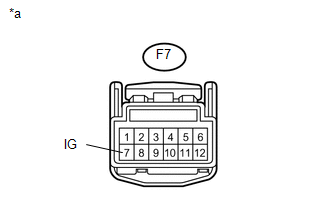

*a |

Front view of wire harness connector (to Tire Pressure Warning ECU) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK HARNESS AND CONNECTOR (ECU - BODY GROUND) |

|

(a) Disconnect the F7 ECU connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F7-9 (GND) - Body ground |

Always |

Below 1 Ω |

|

*a |

Front view of wire harness connector (to Tire Pressure Warning ECU) |

| OK | .gif) |

REPLACE TIRE PRESSURE WARNING ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Tire Pressure Warning Light Circuit

Tire Pressure Warning Light Circuit

DESCRIPTION

If the tire pressure warning ECU detects a disconnected connector or an open

circuit between the tire pressure warning ECU and combination meter, the tire pressure

warning light turns ...

TC and CG Terminal Circuit

TC and CG Terminal Circuit

DESCRIPTION

DTC output mode is set by connecting terminals 13 (TC) and 4 (CG) of the DLC3.

The DTCs are output by the blinking of the tire pressure warning light.

WIRING DIAGRAM

HINT:

When eac ...

Other materials about Toyota 4Runner:

Trailer towing tips

Your vehicle will handle differently when towing a trailer. Help to avoid an

accident, death or serious injury, keep the following in mind when towing:

• Speed limits for towing a trailer vary by state or province. Do not exceed

the posted towing speed ...

Brake Warning Light Remains ON

DESCRIPTION

The BRAKE warning light comes on when brake fluid is insufficient, the parking

brake is applied or the EBD is defective.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When replacing the master cylinder solenoid, perform calibration (See p ...

0.0234

.gif)