Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

1. INSPECT TIE ROD END SUB-ASSEMBLY

|

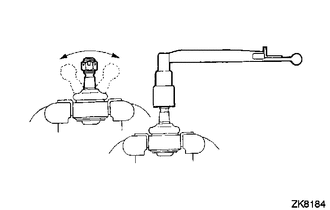

(a) Install the nut. |

|

(b) Flip the ball joint stud back and forth 5 times as shown in the illustration.

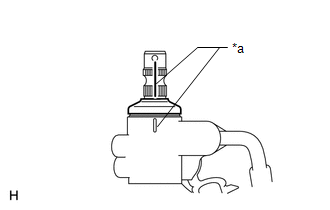

(c) Using a torque wrench, turn the nut continuously at a rate of 3 to 5 seconds per turn and check the torque reading on the 5th turn.

Standard Torque:

1.0 to 3.9 N*m (10 to 39 kgf*cm, 9 to 34 in.*lbf)

2. INSPECT TOTAL PRELOAD

|

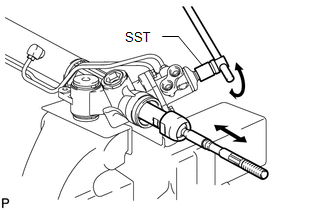

(a) Place matchmarks as shown in the illustration. Text in Illustration

|

|

(b) Temporarily install the 2 steering rack ends to the steering rack.

NOTICE:

Do not fully turn the steering rack without the steering rack ends installed as it may damage the oil seal in the rack housing.

|

(c) Using SST, fully turn the steering rack right and left 10 times to settle it. SST: 09616-00011 |

|

|

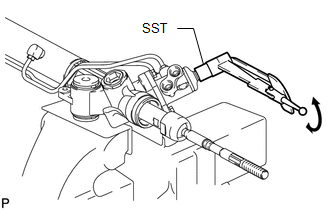

(d) Using SST, turn the control valve and measure the preload. SST: 09616-00011 Standard preload (turning): 1.6 to 2.3 N*m (16 to 23 kgf*cm, 14 to 20 in.*lbf) If the turning torque is not as specified, replace the steering gear assembly. HINT:

|

|

(e) After inspecting the preload, align the matchmarks.

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

When using a vise, do not overtighten it.

PROCEDURE

1. REMOVE TIE ROD END SUB-ASSEMBLY LH

(a) Put matchmarks on the tie rod end LH and stee ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL STEERING RACK END SUB-ASSEMBLY

(a) Temporarily install the 2 steering rack ends to the steering rack.

(b) Fill up the ball joints of the steering rack ends with MP ...

Other materials about Toyota 4Runner:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE REAR PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

HINT:

Use the same procedure for all rear propeller shaft universal joint spider bearing.

(a) Place matchmarks on the flange yoke and sleeve yoke.

Text in Il ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT NAVIGATION ANTENNA ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Condition

Specif ...

0.0257