Toyota 4Runner: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL STEERING RACK END SUB-ASSEMBLY

(a) Temporarily install the 2 steering rack ends to the steering rack.

(b) Fill up the ball joints of the steering rack ends with MP grease.

|

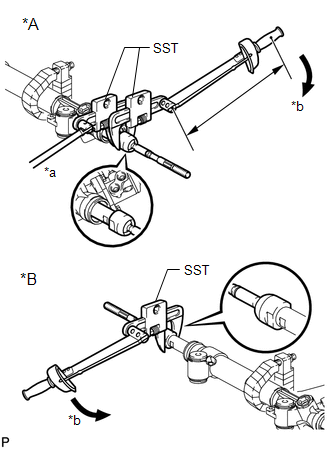

(c) Using SST, install the steering rack end (RH side) to the steering rack. SST: 09922-10010 Torque: without SST : 105 N·m {1071 kgf·cm, 77 ft·lbf} with SST : 77 N·m {784 kgf·cm, 57 ft·lbf} Text in Illustration

HINT:

|

|

(d) Using SST and a wrench, install the steering rack end (LH side) to the steering rack.

SST: 09922-10010

Torque:

without SST :

105 N·m {1071 kgf·cm, 77 ft·lbf}

with SST :

77 N·m {784 kgf·cm, 57 ft·lbf}

HINT:

- Rotate SST in the direction shown in the illustration.

- Use a torque wrench with a fulcrum length of 400 mm (15.75 in.).

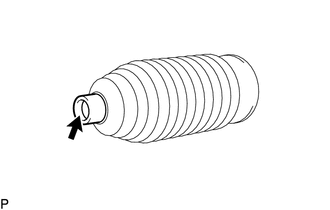

2. INSTALL NO. 2 STEERING RACK BOOT

|

(a) Apply silicon grease to the inside of the small opening of the boot. |

|

(b) Install the 2 boots to the groove on the rack housing.

3. INSTALL NO. 1 STEERING RACK BOOT

HINT:

Use the same procedures described for No. 2 boot.

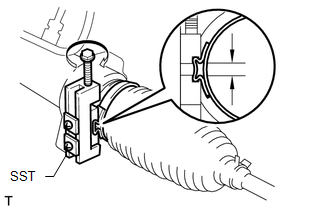

4. INSTALL STEERING RACK BOOT CLAMP RH

|

(a) Using SST, install a new boot clamp as shown in the illustration. SST: 09521-24010 Standard clearance: 3.0 mm (0.118 in.) or less NOTICE: Be careful not to damage the boot. |

|

5. INSTALL STEERING RACK BOOT CLAMP LH

HINT:

Use the same procedures described for the RH side.

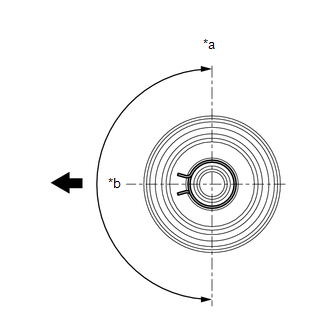

6. INSTALL STEERING RACK BOOT CLIP RH

(a) Using pliers, install the boot clip.

Text in Illustration

Text in Illustration

|

*a |

Upward |

|

*b |

180° |

.png) |

Front of Vehicle |

NOTICE:

Make sure that the claws of the clip are positioned within the area shown in the illustration.

7. INSTALL STEERING RACK BOOT CLIP LH

HINT:

Use the same procedures described for the RH side.

8. INSTALL STEERING GEAR OUTLET RETURN TUBE

(a) Using a union nut wrench, install the return tube to the steering gear.

Torque:

25 N·m {255 kgf·cm, 18 ft·lbf}

HINT:

Use the formula to calculate special torque values for situations where a union

nut wrench is combined with a torque wrench (See page

.gif) ).

).

9. INSTALL TURN PRESSURE TUBE

(a) Apply steering fluid to 2 new O-rings. Using a union nut wrench, install the 2 O-rings and turn pressure tube LH.

Torque:

13 N·m {127 kgf·cm, 9 ft·lbf}

HINT:

Use the formula to calculate special torque values for situations where a union

nut wrench is combined with a torque wrench (See page

.gif) ).

).

(b) Apply steering fluid to 2 new O-rings. Using a union nut wrench, install the 2 O-rings and turn pressure tube RH.

Torque:

13 N·m {127 kgf·cm, 9 ft·lbf}

HINT:

Use the formula to calculate special torque values for situations where a union

nut wrench is combined with a torque wrench (See page

.gif) ).

).

10. INSTALL TIE ROD END SUB-ASSEMBLY LH

(a) Align the matchmarks of the tie rod and rack end, and temporarily install the tie rod with the lock nut.

HINT:

After adjusting toe-in, tighten the lock nut.

Torque:

88 N·m {897 kgf·cm, 65 ft·lbf}

11. INSTALL TIE ROD END SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT TIE ROD END SUB-ASSEMBLY

(a) Install the nut.

(b) Flip the ball joint stud back and forth 5 times as shown in t ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL RACK AND PINION POWER STEERING GEAR ASSEMBLY

(a) Insert the power steering gear assembly into the vehicle in the order shown

in the illustration.

...

Other materials about Toyota 4Runner:

Tire inflation pressure

Tire inflation pressure

The recommended cold tire inflation pressure and tire size are displayed on

the tire and loading information label.

Inspection and adjustment procedure

1. Tire valve 2. Tire pressure gauge

Remove the tire valve cap.

Press t ...

Rear Upper Arm

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. REMOVE REAR UPPE ...

0.0115