Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

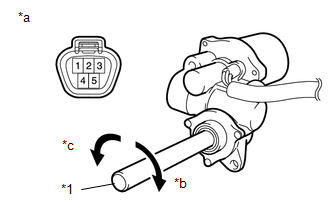

1. INSPECT SIDE AUTO STEP MOTOR ASSEMBLY

|

(a) Check that the motor gear rotates smoothly as follows. NOTICE: Do not apply positive (+) battery voltage to any terminals except terminal 5 and 4 to avoid damaging the pulse sensor inside the motor. OK:

CAUTION: Reset the side auto step motor assembly (initialize the pulse sensor) after installing the side auto step motor assembly and side auto step assembly. Text in Illustration

|

|

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE STEP PLATE COVER LH

...

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. INSTALL POWER LIFT STEP AS ...

Other materials about Toyota 4Runner:

Manual Shifting Test

MANUAL SHIFTING TEST

1. MANUAL SHIFTING TEST

HINT:

Through this test, it can be determined whether the trouble occurs in

an electrical circuit or if it is a mechanical problem in the transmission.

If any abnormalities are found in the fol ...

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

When installing the window frame moulding, black out tape and outside

stripe, heat the vehicle body ...

0.0073