Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

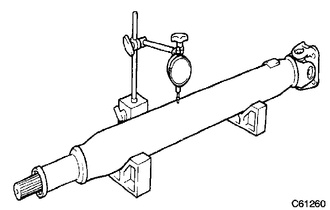

1. INSPECT PROPELLER SHAFT ASSEMBLY

|

(a) Using a dial indicator, check the propeller shaft runout. Maximum runout: 0.4 mm (0.0157 in.) If the shaft runout is more than the maximum, replace the shaft. |

|

2. INSPECT REAR PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

NOTICE:

Be careful not to grip the propeller shaft tube too tightly in a vise as this will cause deformation.

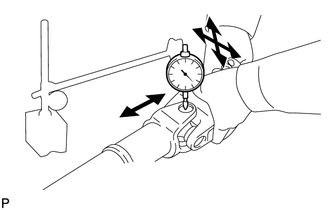

(a) Check the spider bearings for wear or damage.

If necessary, replace the spider bearing.

|

(b) Check the spider bearing axial play by turning the yoke while holding the shaft tightly. Maximum bearing axial play: 0 mm (0 in.) If the axial play is more than the maximum, replace the spider bearing. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE PROPELLER SHAFT ASSEMBLY

(a) Place matchmarks on the propeller shaft flange and differential flange.

Text in Illustration

*a

...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

HINT:

Use the same procedure for all rear propeller shaft universal joint spider bearing.

(a) Apply ...

Other materials about Toyota 4Runner:

CD cannot be Inserted / Played or CD is Ejected Right After Insertion

PROCEDURE

1.

CHECK IF A PROPER CD IS INSERTED

(a) Make sure that the CD is an audio CD or a CD with an MP3, WMA or AAC file,

and that it is not deformed, flawed, stained, deteriorated or otherwise defective.

OK:

CD is nor ...

Terminals Of Ecu

TERMINALS OF ECU

HINT:

Operating the ignition switch, any switches or any doors triggers related ECU

and sensor communication with the CAN, which causes resistance variation.

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

(a) Disconnect the cable fro ...

0.0262