Toyota 4Runner: Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

- Always use a new grommet and valve core when installing the tire pressure warning valve and transmitter.

- Check that the washer and nut are not damaged, and replace them if necessary.

- Make sure not to damage the urethane covered backside of the tire pressure warning valve and transmitter (the surface opposite to the side with the ID code) with anything sharp.

- If installing a new tire pressure warning valve and transmitter, write down the ID number before installation.

- Check that there is no oil, water or lubricant around the rim hole, tire pressure warning valve and transmitter, washer and nut. Failing to do so may result in improper installation.

- Use only a specified valve cap. If an unspecified valve cap is used, it may seize to the tire pressure warning valve and transmitter.

PROCEDURE

1. INSTALL TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Install a new grommet to the tire pressure warning valve and transmitter.

NOTICE:

Do not install a grommet to a new tire pressure warning valve and transmitter, as a new tire pressure warning valve and transmitter has a grommet already installed.

|

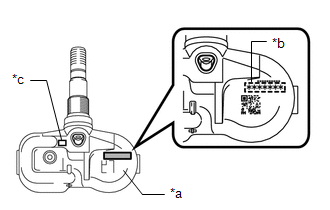

(b) Record the 7-digit number transmitter ID printed on the tire pressure warning valve and transmitter at the position shown in the illustration. Text in Illustration

|

|

(c) Insert the tire pressure warning valve and transmitter into the valve installation hole from the inside of the rim so that the printed surface can be seen.

NOTICE:

- Check that there is no visible deformation, damage, or other abnormalities on the tire pressure warning valve and transmitter.

- Check that there is no foreign matter on the grommet and around the rim hole.

- If the tire pressure warning valve and transmitter is installed upside down, it may be damaged or fail to transmit signals when driving at high speeds.

|

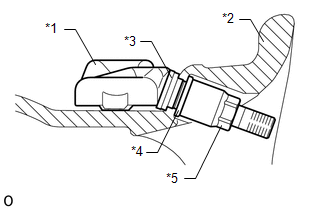

(d) From the outside of the rim, install the washer to the tire pressure warning valve and transmitter, which has the grommet installed. Afterward, using an 11 mm deep socket wrench, tighten the nut. Torque: 4.0 N·m {41 kgf·cm, 35 in·lbf} Text in Illustration

NOTICE:

|

|

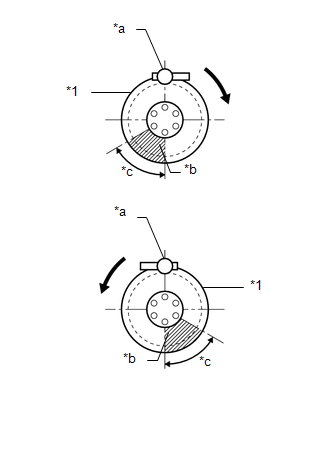

(e) Set the tire and disc wheel onto the mounting machine.

Text in Illustration

Text in Illustration

|

*1 |

Rim |

|

*a |

Mount Tool of Mounting Machine |

|

*b |

Area for Tire Pressure Warning Valve and Transmitter |

|

*c |

60° |

.png) |

Rim Rotation Direction |

NOTICE:

- Make sure the tire pressure warning valve and transmitter is positioned

in the area shown in the illustration when set to the mounting machine.

Otherwise, the tire pressure warning valve and transmitter may interfere with the tire bead and become damaged.

- Position the main body of the tire pressure warning valve and transmitter in the area shown in the illustration.

(f) Apply a sufficient coat of soapy water or equivalent to the tire bead and rim.

NOTICE:

Do not apply soapy water or equivalent directly to the tire pressure warning valve and transmitter.

(g) Using a mounting machine, install the tire to the disc wheel.

NOTICE:

- Make sure that the tire bead and mount tool do not interfere with the tire pressure warning valve and transmitter.

- Make sure that the tire pressure warning valve and transmitter is not clamped by the bead and rim.

(h) Install a new valve core.

(i) Adjust the tire pressure to the standard tire pressure.

(j) After the tire is inflated, the valve nut may be loose. Using an 11 mm deep socket wrench, retighten the nut to the specified torque.

Torque:

4.0 N·m {41 kgf·cm, 35 in·lbf}

NOTICE:

No further tightening is required once the nut is tightened to the specified torque.

(k) Check for air leaks with soapy water.

If there is air leakage, push the valve core 2 or 3 times to remove any dirt attached to the valve core.

If air continues to leak, replace the grommet, washer and nut.

(l) Install the valve cap.

2. INSTALL FRONT WHEEL

Torque:

for aluminum wheel :

103 N·m {1050 kgf·cm, 76 ft·lbf}

for steel wheel :

112 N·m {1142 kgf·cm, 83 ft·lbf}

3. INSTALL REAR WHEEL

Torque:

for aluminum wheel :

103 N·m {1050 kgf·cm, 76 ft·lbf}

for steel wheel :

112 N·m {1142 kgf·cm, 83 ft·lbf}

4. INSTALL GROUND SPARE TIRE

5. INSPECT TIRE

(a) Inspect the tire (See page .gif) ).

).

6. REGISTER TRANSMITTER ID

(a) Register the transmitter ID (See page .gif) ).

).

7. CHECK TIRE PRESSURE AFTER REPAIRS

(a) After repairs, confirm that the actual tire pressures are displayed in the

Data List (See page .gif) ).

).

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMOVE REAR WHEEL

3. REMOVE INSTALL GROUND SPARE TIRE

4. REMOVE TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Remove the valve cap and valve core to ...

Disposal

Disposal

DISPOSAL

CAUTION / NOTICE / HINT

HINT:

The tire pressure warning valve and transmitter is powered by a lithium battery.

When disposing of the tire pressure warning valve and transmitter, remove t ...

Other materials about Toyota 4Runner:

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

Rear View Monitor System

DTC No.

Detection Item

Link

C1622

Back Camera Disconnected

...

Dtc Check / Clear

DTC CHECK / CLEAR

HINT:

When using the Techstream with the ignition switch off to troubleshoot:

Connect the Techstream to the vehicle and turn the front door courtesy light

switch LH on and off at 1.5 second intervals until communication betw ...

0.0252