Toyota 4Runner: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

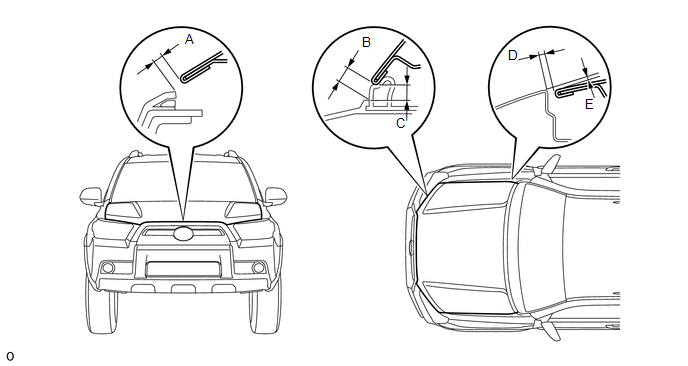

1. INSPECT HOOD SUB-ASSEMBLY

(a) Check that the clearance measurements of areas A through E are within each standard range.

Standard:

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

A |

3.65 to 7.65 mm (0.144 to 0.301 in.) |

B |

5.15 to 9.15 mm (0.203 to 0.360 in.) |

|

C |

4.05 to 8.05 mm (0.165 to 0.323 in.) |

D |

2.0 to 5.0 mm (0.0787 to 0.197 in.) |

|

E |

-1.5 to 1.5 mm (-0.0591 to 0.0591 in.) |

- |

- |

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE HOOD TO RADIATOR SUPPORT SEAL

(a) Using a clip remover, remove the 7 clips and hood to radiator support

seal.

NOTICE:

If the clips are damaged o ...

Adjustment

Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

HINT:

Centering bolts are used to mount the hood hinge and hood lock. The

hood and hood lock cannot be adjusted with the centering bolts installed. ...

Other materials about Toyota 4Runner:

Removal

REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

Some of these service operations affect the SRS airbag system. Read the precautionary

notices concerning the SRS airbag system before servicing the steering wheel (See

page ).

PROCEDURE

1. PLACE FRONT WHEELS F ...

Sliding Roof ECU Communication Stop (B1273)

DESCRIPTION

This DTC is stored when LIN communication between the sliding roof ECU (sliding

roof drive gear sub-assembly) and main body ECU (multiplex network body ECU) stops

for 10 seconds or more.

DTC Code

DTC Detection Condition

...

0.0266