Toyota 4Runner: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL MAGNET CLUTCH ASSEMBLY

(a) Align the parts as shown in the illustration and install the magnet clutch stator.

|

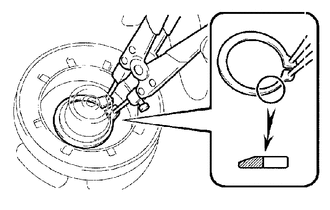

(b) Using a snap ring expander, install a new snap ring with the chamfered side facing up. |

|

(c) Connect the connector.

|

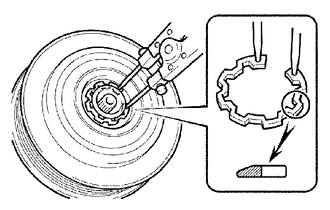

(d) Using a snap ring expander, install the magnet clutch rotor and a new snap ring with the chamfered side facing up. NOTICE: Do not damage the seal cover of the bearing when installing the snap ring. |

|

(e) Install the compressor washer(s) and magnet clutch hub.

NOTICE:

Do not change the combination of compressor washer(s) used before disassembly.

|

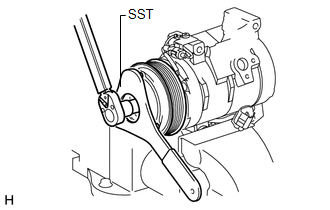

(f) Using SST, hold the magnet clutch hub and install the bolt. SST: 07112-76060 Torque: 18 N·m {184 kgf·cm, 13 ft·lbf} NOTICE: Make sure that there is no foreign matter or oil on the compressor shaft, bolt and clutch hub. |

|

2. INSTALL COOLER BRACKET

(a) Install the cooler bracket with the screw.

(b) Attach the clamp.

3. INSPECT MAGNET CLUTCH CLEARANCE

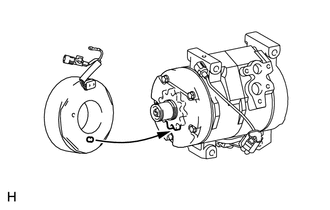

(a) Clamp the cooler compressor in a vise.

(b) Set a dial indicator on the magnet clutch hub.

(c) Connect the positive (+) lead of the battery to terminal 3 of the magnet clutch connector and the negative (-) lead to the ground wire. Turn the magnet clutch on and off and measure the clearance.

Standard clearance:

0.35 to 0.60 mm (0.014 to 0.024 in.)

Text in Illustration|

*1 |

Battery |

|

*a |

Component without harness connected (Magnet Clutch Assembly) |

If the measured value is not within the standard range, remove the magnet clutch hub and adjust the clearance using compressor washers to obtain the standard clearance.

Compressor washer thickness:

0.1 mm (0.004 in.)

0.3 mm (0.012 in.)

0.5 mm (0.020 in.)

NOTICE:

Be sure to perform the adjustment with 3 or fewer magnet clutch washers.

(d) Remove the cooler compressor from the vise.

Installation

Installation

INSTALLATION

PROCEDURE

1. ADJUST COMPRESSOR OIL

(a) When replacing the compressor and magnetic clutch with a new one, gradually

discharge the refrigerant gas from the service valve and drain the ...

Condenser

Condenser

...

Other materials about Toyota 4Runner:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

A bolt without a torque specification is shown in the standard bolt chart (See

page ).

PROCEDURE

1. INSTALL POWER MANAGEMENT CONTROL ECU

(a) Attach the 2 claws to install the power management control ECU.

2. ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE CYLINDER BOOT

(a) Using a screwdriver, remove the cylinder boot from the rear disc

brake cylinder.

HINT:

Tape the screwdriver tip before use.

2. REMOVE REAR DISC ...

0.0269