Toyota 4Runner: Speed Signal Circuit

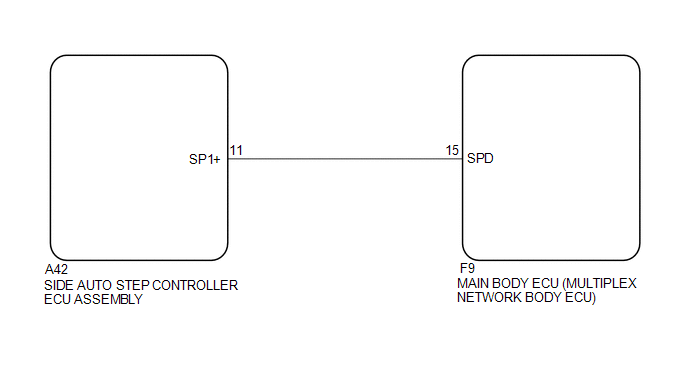

DESCRIPTION

The vehicle speed signal consists of pulses sent to the side auto step controller ECU assembly from the main body ECU (multiplex network body ECU).

WIRING DIAGRAM

PROCEDURE

|

1. |

INSPECT MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

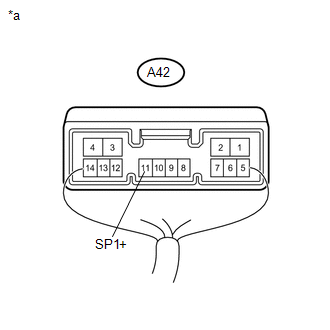

(a) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-11 (SP1+) - Body ground |

Vehicle speed at lower than 8 km/h (5 mph) |

11 to 14 V |

|

Vehicle speed at 8 km/h (5 mph) or more |

Below 1 V |

|

*a |

Component with harness connected (Side Auto Step Controller ECU Assembly) |

|

Result |

Proceed to |

|---|---|

|

NG |

A |

|

OK |

B |

| B | .gif) |

REPLACE SIDE AUTO STEP CONTROLLER ECU ASSEMBLY |

|

|

2. |

CHECK HARNESS AND CONNECTOR (SIDE AUTO STEP ECU - MAIN BODY ECU) |

(a) Disconnect the A42 side auto step controller ECU assembly connector.

(b) Disconnect the F9 main body ECU (multiplex network body ECU) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-11 (SP1+) - F9-15 (SPD) |

Always |

Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-11 (SP1+) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Door Courtesy Switch Circuit

Door Courtesy Switch Circuit

DESCRIPTION

The side auto step controller ECU assembly receives the door open/closed signal

from each door courtesy light switch via the side auto step switch assembly.

WIRING DIAGRAM

CAUTION / ...

Other materials about Toyota 4Runner:

Lumbar Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT LUMBAR SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Switch ...

ECU Initial Setting Incomplete (C120A)

DESCRIPTION

w/ Downhill Assist Control or w/ Crawl Control:

When the master cylinder solenoid (skid control ECU) is replaced, the master

cylinder solenoid (skid control ECU) must be informed that the vehicle is equipped

with downhill assist control and/o ...

0.0074

.gif)