Toyota 4Runner: Transmitter ID1 Operation Stop (C2111/11-C2115/15)

DESCRIPTION

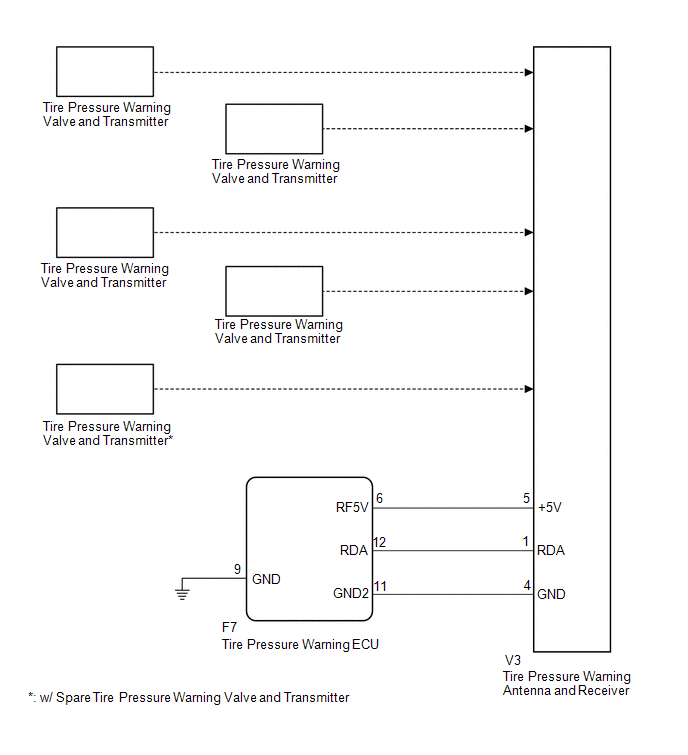

The tire pressure warning valve and transmitters installed in the tire and wheel assemblies measure the tire pressures of the tires. The measured values are transmitted to the tire pressure warning antenna and receiver on the body as radio waves and then sent to the tire pressure warning ECU. The ECU compares the measured tire pressure values with the tire pressure threshold. When the measured tire pressure value is less than this threshold, the warning light in the combination meter turns on. The tire pressure warning ECU stores a DTC when the tire pressure warning valve and transmitter stops transmitting signals. The stored DTC is cleared when the signal transmission is resumed.

|

DTC Code |

Detection Condition |

Trouble Area |

|---|---|---|

|

C2111/11 C2112/12 C2113/13 C2114/14 C2115/15* |

The tire pressure warning valve and transmitters stop transmitting signals. |

|

- *: w/ Spare Tire Pressure Warning Valve and Transmitter

HINT:

It is necessary to perform this procedure in order to identify the malfunctioning tire pressure warning valve and transmitter because it cannot be identified by the output DTCs.

WIRING DIAGRAM

PROCEDURE

|

1. |

PERFORM FORCED TRANSMISSION OF TRANSMITTER ID OF ALL WHEELS |

(a) Set the tire pressure to the specified value (See page

.gif) ).

).

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Check the values by referring to the table below.

Tire Pressure Monitor|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

ID1 Tire Inflation Pressure |

ID1 tire inflation pressure / min.: Absolute pressure 0.0 kPa (0.0 kgf/cm2, 0.0 psi), Relative pressure -100.0 kPa (-1.0 kgf/cm2, -14 psi) max.: Absolute pressure 637.5 kPa (6.5 kgf/cm2, 92 psi), Relative pressure 537.5 kPa (5.4 kgf/cm2, 78 psi) |

Actual tire inflation pressure |

If 0 kPa (0.0 kgf/cm2, 0.0 psi) is displayed for absolute pressure or -100 kPa (-1.0 kgf/cm2, -14 psi) is displayed for relative pressure, data has not been received.*1 |

|

ID2 Tire Inflation Pressure |

ID2 tire inflation pressure / min.: Absolute pressure 0.0 kPa (0.0 kgf/cm2, 0.0 psi), Relative pressure -100.0 kPa (-1.0 kgf/cm2, -14 psi) max.: Absolute pressure 637.5 kPa (6.5 kgf/cm2, 92 psi), Relative pressure 537.5 kPa (5.4 kgf/cm2, 78 psi) |

Actual tire inflation pressure |

If 0 kPa (0.0 kgf/cm2, 0.0 psi) is displayed for absolute pressure or -100 kPa (-1.0 kgf/cm2, -14 psi) is displayed for relative pressure, data has not been received.*1 |

|

ID3 Tire Inflation Pressure |

ID3 tire inflation pressure / min.: Absolute pressure 0.0 kPa (0.0 kgf/cm2, 0.0 psi), Relative pressure -100.0 kPa (-1.0 kgf/cm2, -14 psi) max.: Absolute pressure 637.5 kPa (6.5 kgf/cm2, 92 psi), Relative pressure 537.5 kPa (5.4 kgf/cm2, 78 psi) |

Actual tire inflation pressure |

If 0 kPa (0.0 kgf/cm2, 0.0 psi) is displayed for absolute pressure or -100 kPa (-1.0 kgf/cm2, -14 psi) is displayed for relative pressure, data has not been received.*1 |

|

ID4 Tire Inflation Pressure |

ID4 tire inflation pressure / min.: Absolute pressure 0.0 kPa (0.0 kgf/cm2, 0.0 psi), Relative pressure -100.0 kPa (-1.0 kgf/cm2, -14 psi) max.: Absolute pressure 637.5 kPa (6.5 kgf/cm2, 92 psi), Relative pressure 537.5 kPa (5.4 kgf/cm2, 78 psi) |

Actual tire inflation pressure |

If 0 kPa (0.0 kgf/cm2, 0.0 psi) is displayed for absolute pressure or -100 kPa (-1.0 kgf/cm2, -14 psi) is displayed for relative pressure, data has not been received.*1 |

|

ID5 Tire Inflation Pressure*2 |

ID5 tire inflation pressure/ min.: Absolute pressure 0.0 kPa (0.0 kgf/cm2, 0.0 psi), Relative pressure -100.0 kPa (-1.0 kgf/cm2, -14 psi) max.: Absolute pressure 637.5 kPa (6.5 kgf/cm2, 92 psi), Relative pressure 537.5 kPa (5.4 kgf/cm2, 78 psi) |

Actual tire inflation pressure |

If 0 kPa (0.0 kgf/cm2, 0.0 psi) is displayed for absolute pressure or -100 kPa (-1.0 kgf/cm2, -14 psi) is displayed for relative pressure, data has not been received.*1 |

HINT:

- *1: It may take approximately 2 or 3 minutes until the values are displayed.

If the values are not displayed after a few minutes, perform troubleshooting

according to the inspection procedure for DTCs C2121/21 to C2124/24 or C2125/25*2

(See page

.gif) ).

). - *2: w/ Spare Tire Pressure Warning Valve and Transmitter

(g) Rapidly reduce the tire pressure of each tire by at least 40 kPa (0.4 kgf/cm2, 5.8 psi) within 30 seconds.

(1) Check that tire pressure data for each tire displayed on the Techstream screen has changed.

OK:

Tire pressure data for each tire displayed on the Techstream changes to the value of the tire pressure.

NOTICE:

- It takes approximately 2 or 3 minutes to display the updated tire pressure data.

- When the "ID Tire Inflation Pressure" data has not changed, reset the tire pressure to the appropriate specified value and rotate the tire 90 to 270°. Then rapidly release the tire pressure and recheck it.

(2) After confirming that all of the tire pressure data displayed on the Techstream screen has changed, set the tire pressure of all tires to the specified values.

HINT:

If the tire pressure data displayed on the Techstream has not changed after rechecking

it, inspect for other problems (malfunction in transmission or reception function)

(See page .gif) ).

).

| OK | .gif) |

END |

| NG | .gif) |

INSPECT FOR OTHER PROBLEM (MALFUNCTION IN TRANSMISSION OR RECEPTION FUNCTION) |

Transmitter ID1 Error (C2141/41-C2145/45)

Transmitter ID1 Error (C2141/41-C2145/45)

DESCRIPTION

The tire pressure warning valve and transmitters that are installed in the tire

and wheel assemblies measure the air pressure of the tires. The measured values

are transmitted to the ...

Vehicle Speed Signal Error (Test Mode DTC) (C2191/91)

Vehicle Speed Signal Error (Test Mode DTC) (C2191/91)

DESCRIPTION

The tire pressure warning ECU receives a vehicle speed signal from the combination

meter. This DTC is stored upon entering test mode and cleared when a vehicle speed

signal of 20 km/h ...

Other materials about Toyota 4Runner:

Front Speed Sensor RH Performance (C1409,C1410)

DESCRIPTION

Refer to DTCs C1401 and C1402 (See page ).

DTC Code

DTC Detection Condition

Trouble Area

C1409

C1410

One of the following conditions is met:

When the vehicle is driven ...

Lost Communication with Door Side Airbag Sensor RH (B1692/81,B1697/82)

DESCRIPTION

The circuit for the side collision sensor LH or RH (to determine deployment of

the front seat side airbag LH or RH and curtain shield airbag LH or RH) is composed

of the center airbag sensor, rear airbag sensor LH or RH and side airbag sensor ...

0.0177