Toyota 4Runner: Automatic Running Board Switch

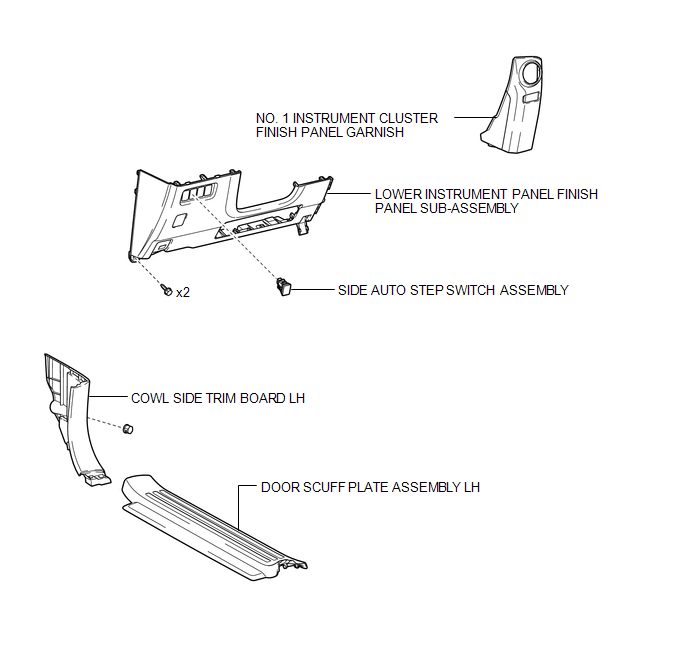

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE DOOR SCUFF PLATE ASSEMBLY LH

.gif)

2. REMOVE COWL SIDE TRIM BOARD LH

.gif)

3. REMOVE NO. 1 INSTRUMENT CLUSTER FINISH PANEL GARNISH

.gif)

4. REMOVE LOWER INSTRUMENT PANEL FINISH PANEL SUB-ASSEMBLY

.gif)

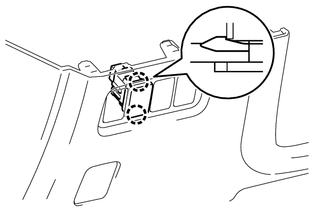

5. REMOVE SIDE AUTO STEP SWITCH ASSEMBLY

|

(a) Disengage the 2 claws and remove the side auto step switch assembly. |

|

Inspection

INSPECTION

PROCEDURE

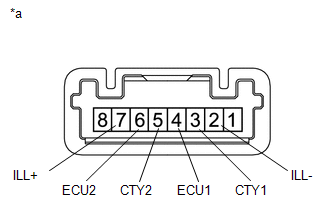

1. INSPECT SIDE AUTO STEP SWITCH ASSEMBLY

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Apply battery voltage to the connector and check the LED illumination.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → Terminal 7 (ILL+) Battery negative (-) → Terminal 2 (ILL-) |

LED illuminates |

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

A bolt without a torque specification is shown in the standard bolt chart (See

page .gif) ).

).

PROCEDURE

1. INSTALL SIDE AUTO STEP SWITCH ASSEMBLY

(a) Engage the 2 claws and install the side auto step switch assembly.

2. INSTALL LOWER INSTRUMENT PANEL FINISH PANEL SUB-ASSEMBLY

.gif)

3. INSTALL NO. 1 INSTRUMENT CLUSTER FINISH PANEL GARNISH

.gif)

4. INSTALL COWL SIDE TRIM BOARD LH

.gif)

5. INSTALL DOOR SCUFF PLATE ASSEMBLY LH

.gif)

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

battery terminal to disable the SRS sys ...

Other materials about Toyota 4Runner:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. INSTALL FRONT AXLE HUB SUB-ASSEMBLY LH

(a) Apply MP grease to a new O-ring.

(b) Inst ...

For owners

Reporting safety defects for U.S. owners, and seat belt and SRS airbag

instructions for Canadian owners.

Reporting safety defects for U.S. owners

If you believe that your vehicle has a defect which could cause a crash or

could cause injury or death, you ...

0.0183