Toyota 4Runner: Headlight (HI-BEAM) Circuit

DESCRIPTION

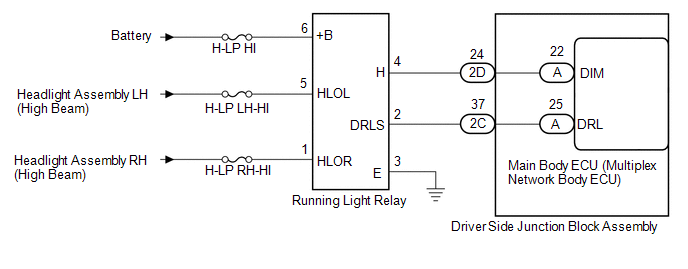

The main body ECU (multiplex network body ECU) receives headlight dimmer switch information signals, and illuminates the high beam headlight.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses and bulbs for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM (DAYTIME RUNNING LIGHT) |

(a) Using the Techstream, perform the Active Test (See page

.gif) ).

).

Main Body

|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Daytime Running Light |

Running light relay |

ON/OFF |

- |

|

Head Light Hi |

Running light relay |

ON/OFF |

- |

OK:

Running light relay operates (high beam headlights illuminate).

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

CHECK HARNESS AND CONNECTOR (BATTERY - RUNNING LIGHT RELAY) |

(a) Remove the running light relay from the engine room relay block, junction block.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Running light relay terminal 6 (+B) - Body ground |

Always |

11 to 14 V |

|

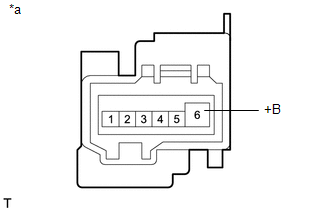

*a |

Front view of wire harness connector (to Running Light Relay) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (RUNNING LIGHT RELAY - DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

(a) Remove the running light relay from the engine room relay block, junction block.

(b) Disconnect the 2C and 2D driver side junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Running light relay terminal 4 (H) - 2D-24 |

Always |

Below 1 Ω |

|

Running light relay terminal 2 (DRLS) - 2C-37 |

Always |

Below 1 Ω |

|

Running light relay terminal 3 (E) - Body ground |

Always |

Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Running light relay terminal 4 (H) or 2D-24 - Body ground |

Always |

10 kΩ or higher |

|

Running light relay terminal 2 (DRLS) or 2C-37 - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

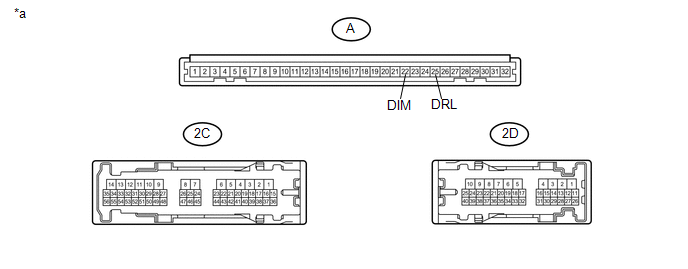

CHECK DRIVER SIDE JUNCTION BLOCK ASSEMBLY |

(a) Remove the driver side junction block assembly (See page

.gif) ).

).

(b) Remove the main body ECU (multiplex network body ECU) from the driver side junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2D-24 - A-22 (DIM) |

Always |

Below 1 Ω |

|

2C-37 - A-25 (DRL) |

Always |

Below 1 Ω |

|

*a |

Component without harness connected (Driver Side Junction Block Assembly) |

- |

- |

| NG | .gif) |

REPLACE DRIVER SIDE JUNCTION BLOCK ASSEMBLY |

|

|

5. |

REPLACE RUNNING LIGHT RELAY |

(a) Replace the running light relay.

(b) Check that the daytime running lights operate normally (See page

.gif) ).

).

OK:

The daytime running lights operate normally.

| OK | .gif) |

END (RUNNING LIGHT RELAY WAS DEFECTIVE) |

| NG | .gif) |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

Headlight Relay Circuit

Headlight Relay Circuit

DESCRIPTION

The main body ECU receives headlight dimmer switch information signals, and illuminates

the low beam headlight.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses an ...

Front Fog Light Circuit

Front Fog Light Circuit

DESCRIPTION

The main body ECU receives headlight dimmer switch information signals, and illuminates

the front fog light.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses and b ...

Other materials about Toyota 4Runner:

Crawl Control

Allows travel on extremely rough off-road surfaces at a fixed low speed

without pressing the accelerator or brake pedal. Minimizes loss of traction or

vehicle slip when driving on slippery road surfaces, allowing for stable

driving.

Crawl Control switch ...

Customize Parameters

CUSTOMIZE PARAMETERS

1. CUSTOMIZING FUNCTION WITH TECHSTREAM

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Record the current settings before customizing.

When troubleshoo ...

0.0255

.gif)