Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

1. INSPECT HEADLIGHT DIMMER SWITCH ASSEMBLY

|

(a) Inspect the light control switch. (1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Inspect the headlight dimmer switch.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

11 (HU) - 12 (EL) |

Headlight dimmer switch flash |

Below 1 Ω |

|

17 (HF) - 12 (EL) |

||

|

11 (HU) - 12 (EL) |

Headlight dimmer switch hi beam |

Below 1 Ω |

HINT:

Perform the flash and high beam inspection with the light control switch set to head.

(c) Inspect the turn signal switch.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

13 (TR) - 12 (EL) |

Turn signal switch right turn |

Below 1 Ω |

|

13 (TR) - 12 (EL) |

Turn signal switch right lane change |

Below 1 Ω |

|

13 (TR) - 12 (EL) |

Turn signal switch neutral |

10 kΩ or higher |

|

15 (TL) - 12 (EL) |

||

|

15 (TL) - 12 (EL) |

Turn signal switch left lane change |

Below 1 Ω |

|

15 (TL) - 12 (EL) |

Turn signal switch left turn |

Below 1 Ω |

(d) Inspect the fog light switch.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

4 (BFG) - 3 (LFG) |

Fog light switch off |

10 kΩ or higher |

|

4 (BFG) - 3 (LFG) |

Front fog light switch on |

Below 1 Ω |

If the result is not as specified, replace the headlight dimmer switch.

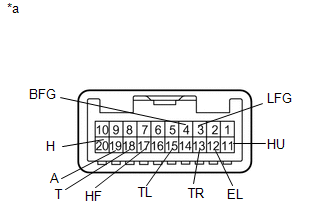

Text in Illustration|

*a |

Component without harness connected (Headlight Dimmer Switch Assembly) |

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE SPIRAL CABLE SUB-ASSEMBLY

(a) Remove the spiral cable sub-assembly (See page

).

2. REMOVE WINDSHIELD WIPER SWITCH ASSEMBLY

3. REMOVE HEADLIGHT DIMMER SWITCH ASSEM ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL HEADLIGHT DIMMER SWITCH ASSEMBLY

(a) Install the headlight dimmer switch to the steering column, making

sure that the stopper protrusions and cutout ...

Other materials about Toyota 4Runner:

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

When installing, coat the parts indicated by arrows with lithium soap

base glycol grease (See page ).

As high pressure is applied to the brake actuator tube No. 1, never

deform it.

Do not turn ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT DOOR CONTROL SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Condition

Speci ...

0.0085