Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

1. INSPECT MAGNET CLUTCH ASSEMBLY

(a) Check the magnet clutch operation.

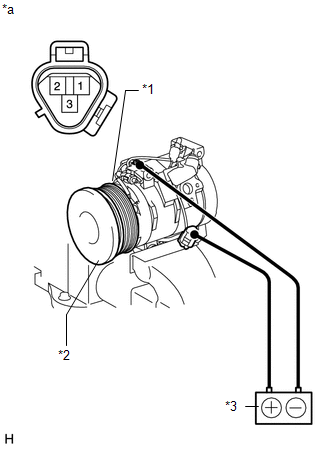

(1) Confirm that the magnet clutch hub and magnet clutch rotor lock when the positive (+) lead of the battery is connected to terminal 3 of the magnet clutch, and the negative (-) lead is connected to the ground wire.

If the operation is not as specified, replace the magnet clutch assembly.

Text in Illustration|

*1 |

Magnet Clutch Rotor |

|

*2 |

Magnet Clutch Hub |

|

*3 |

Battery |

|

*a |

Component without harness connected (Magnet Clutch Assembly) |

(b) Measure the resistance between terminals 1 and 2.

Standard resistance:

65 to 125 Ω at 20°C (68°F)

If the result is not as specified, replace the cooler compressor assembly.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE COOLER BRACKET

(a) Detach the clamp.

(b) Remove the screw and cooler bracket.

2. REMOVE MAGNET CLUTCH ASSEMBLY

(a) Clamp the cooler compressor in a vise.

(b) ...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE GENERATOR ASSEMBLY

(a) Remove the generator assembly (See page

).

2. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

3. DISCONNECT DISCHARGE HOSE SUB-ASSEMBLY

...

Other materials about Toyota 4Runner:

Reassembly

REASSEMBLY

PROCEDURE

1. BEARING POSITION

Bearing and Race Diameter:

Mark

Front Race Diameter Inside/Outside

Thrust Bearing Diameter Inside/Outside

Rear Race Diameter Inside/Outside

A

...

Inspection

INSPECTION

PROCEDURE

1. INSPECT LEVEL WARNING SWITCH ASSEMBLY

HINT:

The following check should be performed with the windshield washer motor and

pump installed to the washer jar.

(a) Fill the washer jar with washer fluid.

(b) Measure the res ...

0.0086