Toyota 4Runner: Inspection

INSPECTION

PROCEDURE

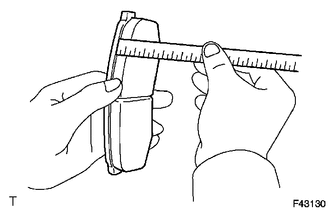

1. CHECK PAD LINING THICKNESS

|

(a) Using a ruler, measure the pad lining thickness. Standard thickness: 10.0 mm (0.394 in.) Minimum thickness: 1.0 mm (0.0394 in.) If the pad lining thickness is less than the minimum, replace the pad. |

|

2. CHECK DISC THICKNESS

|

(a) Using a micrometer, measure the disc thickness. Standard thickness: 18.0 mm (0.709 in.) Minimum thickness: 16.0 mm (0.630 in.) If the disc thickness is less than the minimum, replace the disc. |

|

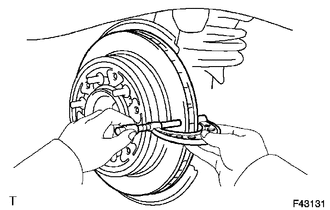

3. CHECK DISC RUNOUT

|

(a) Install the disc with the 6 hub nuts. Torque: for aluminum wheel : 103 N·m {1050 kgf·cm, 76 ft·lbf} for steel wheel : 112 N·m {1142 kgf·cm, 83 ft·lbf} |

|

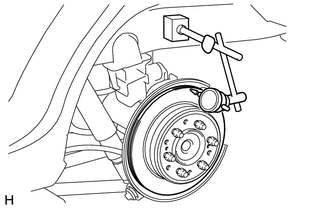

(b) Using a dial indicator, measure the disc runout 10 mm (0.394 in.) from the outer edge of the disc.

Maximum disc runout:

0.20 mm (0.00787 in.)

If the disc runout is more than the maximum, check the rear axle shaft (See page

.gif) ). If the rear axle shaft is normal, adjust the

). If the rear axle shaft is normal, adjust the

disc runout or grind the disc using an on-vehicle brake lathe.

4. ADJUST DISC RUNOUT

(a) Remove the 2 bolts and rear disc brake cylinder mounting from the backing plate.

(b) Remove the hub nuts and disc. Rotate the disc 1/5 of a turn from its original position on the hub and install the disc with the hub nuts.

Torque:

for aluminum wheel :

103 N·m {1050 kgf·cm, 76 ft·lbf}

for steel wheel :

112 N·m {1142 kgf·cm, 83 ft·lbf}

(c) Measure the disc runout. Make a note of the runout and the disc position on the hub.

(d) Repeat the 2 previous steps until the disc has been installed on the 3 remaining hub positions. If the minimum runout recorded above is less than 0.20 mm (0.00787 in.), install the disc in that position. If the minimum runout recorded above is more than 0.20 mm (0.00787 in.), replace the disc and repeat the "Check Disc Runout" procedure.

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. DRAIN BRA ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL PISTON SEAL

(a) Apply a light layer of lithium soap base glycol grease to the entire

inner and outer circumference of a new piston seal.

Text in Il ...

Other materials about Toyota 4Runner:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Adjusting the position of and opening and closing the air outlets

Front center outlets

1. Direct air flow to the left or right, up or down.

2. Turn the knob to open or close the vent.

Front side outlets

1. Direct air flow to the left or right, up or down.

2. Turn the knob to open or close the vent.

Rear outlets

...

0.0111