Toyota 4Runner: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMOVE DISC BRAKE CYLINDER ASSEMBLY LH

.gif)

3. REMOVE FRONT DISC

.gif)

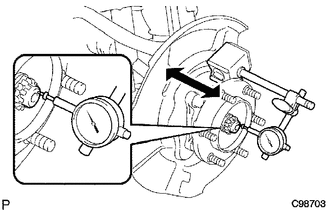

4. INSPECT FRONT AXLE HUB BEARING LOOSENESS

|

(a) Using a dial indicator, measure the looseness near the center of the axle hub. Maximum looseness: 0.05 mm (0.00197 in.) NOTICE: Make sure that the dial indicator is set at a right angle to the measurement surface. If the looseness is more than the maximum, replace the axle hub. |

|

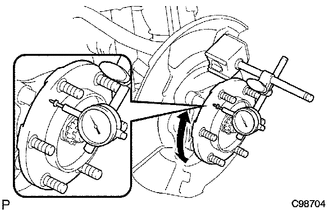

5. INSPECT FRONT AXLE HUB RUNOUT

|

(a) Using a dial indicator, measure the runout on the surface of the axle hub outside the hub bolts. Maximum runout: 0.08 mm (0.00315 in.) NOTICE: Make sure that the dial indicator is set at a right angle to the measurement surface. If the runout is more than the maximum, replace the axle hub. |

|

6. INSTALL FRONT DISC

.gif)

7. INSTALL DISC BRAKE CYLINDER ASSEMBLY LH

.gif)

8. INSTALL FRONT WHEEL

Torque:

for aluminum wheel :

103 N·m {1050 kgf·cm, 76 ft·lbf}

for steel wheel :

112 N·m {1142 kgf·cm, 83 ft·lbf}

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMOVE D ...

Other materials about Toyota 4Runner:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Initialization

INITIALIZATION

1. PROCEDURES NECESSARY WHEN CABLE IS DISCONNECTED/RECONNECTED TO BATTERY TERMINAL

Procedures Necessary when Cable is Disconnected/Reconnected to Battery Terminal

Necessary Procedure

Effect or Inoperative Function when N ...

0.0106