Toyota 4Runner: Rear Differential Lock Control Switch

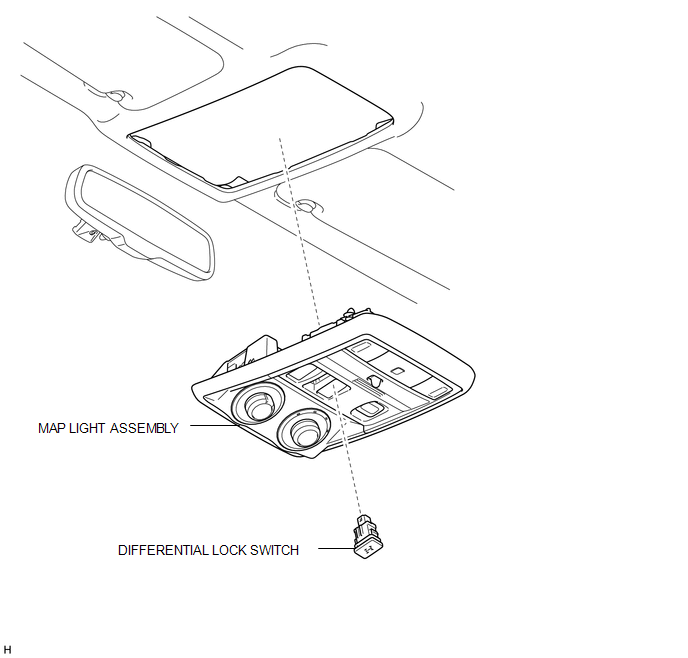

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

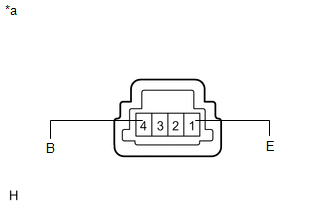

1. INSPECT DIFFERENTIAL LOCK SWITCH

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

1 (E) - 4 (B) |

Pressed |

Below 1 Ω |

|

Not pressed |

100 kΩ or higher |

|

*a |

Component without harness connected (Differential Lock Switch) |

If the result is not as specified, replace the differential lock switch.

Removal

REMOVAL

PROCEDURE

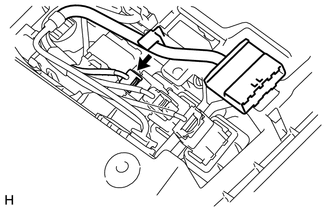

1. REMOVE MAP LIGHT ASSEMBLY

.gif)

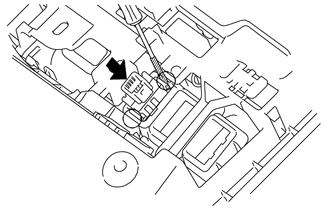

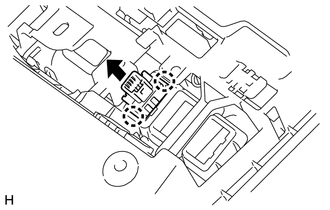

2. REMOVE DIFFERENTIAL LOCK SWITCH

|

(a) Disconnect the differential lock switch connector. |

|

|

(b) Using a screwdriver, detach the 2 claws and remove the differential lock switch from the map light assembly. HINT: Tape the screwdriver tip before use. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL DIFFERENTIAL LOCK SWITCH

|

(a) Attach the 2 claws to install the differential lock switch to the map light assembly. |

|

(b) Connect the connector.

2. INSTALL MAP LIGHT ASSEMBLY

.gif)

Replacement

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE REAR PROPELLER SHAFT ASSEMBLY

(a) for 2WD:

Remove the rear propeller shaft assembly (See page

).

(b) for 4WD:

Remove the rear propeller shaft assembly (See page ...

Rear Differential Lock Position Switch

Rear Differential Lock Position Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT REAR DIFFERENTIAL LOCK POSITION SWITCH

(a) Measure the resistance according to the value(s) in the ...

Other materials about Toyota 4Runner:

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for both the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the c ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT HOOD SUB-ASSEMBLY

(a) Check that the clearance measurements of areas A through E are within each

standard range.

Standard:

Area

Measurement

Area

Measurement

...

0.0118