Toyota 4Runner: Reassembly

REASSEMBLY

PROCEDURE

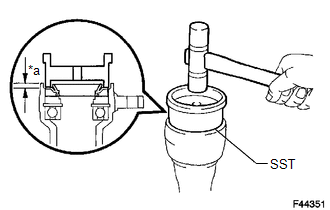

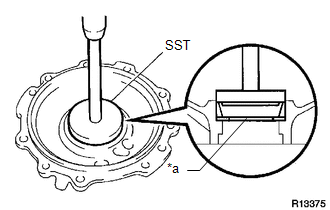

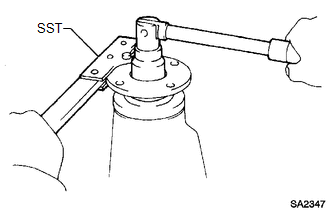

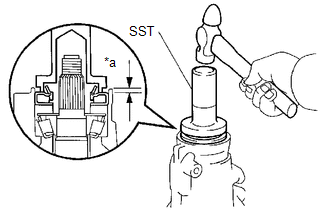

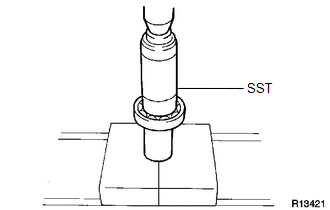

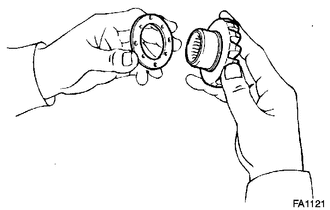

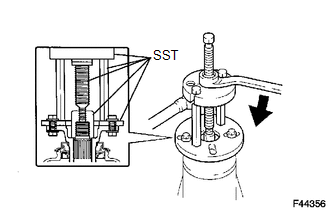

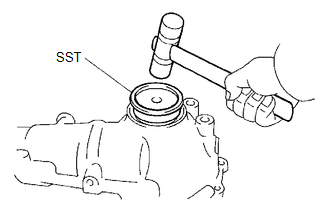

1. INSTALL FRONT DIFFERENTIAL SIDE GEAR SHAFT BEARING RH

(a) Using SST and a press, press in the shaft bearing.

SST: 09223-00010

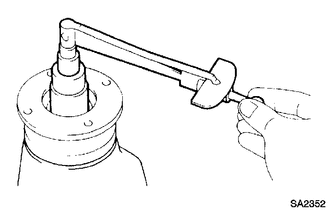

(b) Using a snap ring expander, install the snap ring.

HINT:

Install the snap ring securely.

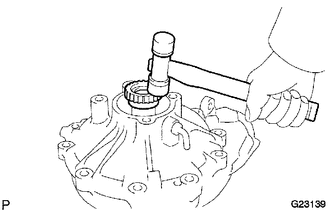

2. INSTALL DIFFERENTIAL SIDE GEAR SHAFT SUB-ASSEMBLY RH

.png)

(a) Install the shaft to the differential tube.

(b) Using snap ring expander, install the snap ring.

HINT:

Install the snap ring securely.

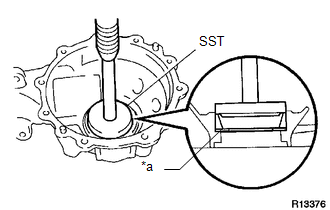

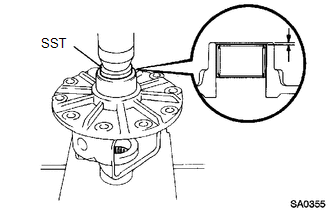

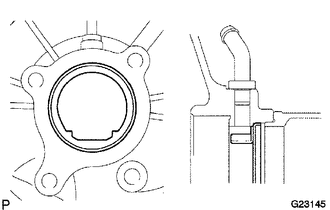

3. INSTALL DIFFERENTIAL SIDE GEAR SHAFT OIL SEAL

(a) Coat the lip of a new oil seal with MP grease.

|

(b) Using SST and a plastic-faced hammer, tap in the oil seal. SST: 09223-15020 Standard oil seal depth: 4.8 to 5.8 mm (0.189 to 0.229 in.) Text in Illustration

|

|

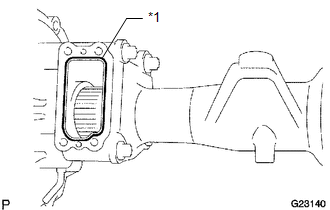

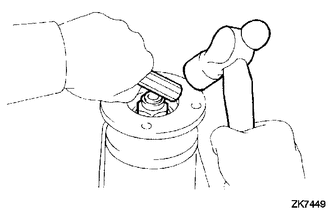

4. INSTALL DIFFERENTIAL CLUTCH HUB (w/ A.D.D.)

(a) Install the clutch hub to the side gear inter shaft.

(b) Using snap ring pliers, install the snap ring.

HINT:

Install the snap ring securely.

NOTICE:

Install the differential clutch hub so that it is facing in the correct direction.

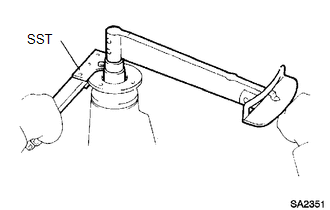

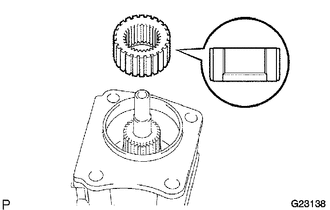

5. INSTALL FRONT DIFFERENTIAL SIDE GEAR NEEDLE ROLLER BEARING (w/ A.D.D.)

(a) Using SST and a press, press in 2 new bearings.

SST: 09950-60010

09951-00380

Standard needle roller bearing depth:

1.4 to 2.0 mm (0.0551 to 0.0787 in.)

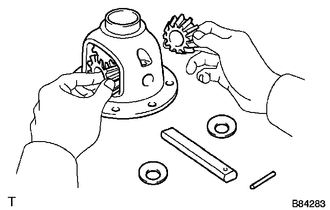

6. INSTALL DIFFERENTIAL CASE ASSEMBLY

(a) Install the 2 thrust washers to the 2 side gears.

Standard Thrust Washer:

|

Specified Condition |

Specified Condition |

|---|---|

|

1.48 to 1.52 mm (0.0583 to 0.0598 in.) |

1.73 to 1.77 mm (0.0681 to 0.0697 in.) |

|

1.53 to 1.57 mm (0.0602 to 0.0618 in.) |

1.78 to 1.82 mm (0.0701 to 0.0717 in.) |

|

1.58 to 1.62 mm (0.0622 to 0.0638 in.) |

1.83 to 1.87 mm (0.0720 to 0.0736 in.) |

|

1.63 to 1.67 mm (0.0642 to 0.0657 in.) |

1.88 to 1.92 mm (0.0740 to 0.0756 in.) |

|

1.68 to 1.72 mm (0.0661 to 0.0677 in.) |

- |

|

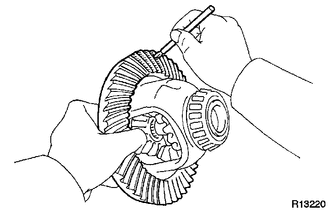

(b) Install the 2 side gears, 2 pinion gears, 2 side gear thrust washers, 2 pinion thrust washers and pinion shaft to the differential case. HINT: Align the holes of the differential case and pinion shaft. |

|

|

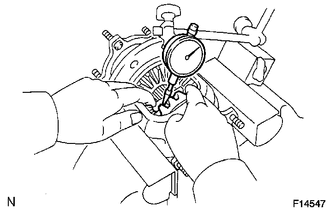

(c) Measure the side gear backlash. (1) Using a dial indicator, measure the side gear backlash while holding one pinion gear toward the differential case. Standard backlash: 0.25 mm (0.00984 in.) or less

|

|

|

(d) Using a 5 mm pin punch and hammer, tap in the straight pin through the differential case and hole of the pinion shaft. |

|

(e) Stake the differential case.

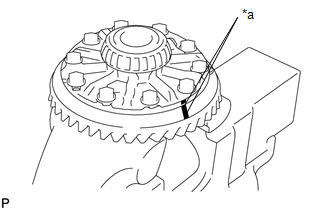

7. INSTALL DIFFERENTIAL RING GEAR

(a) Clean the contact surfaces of the differential case and ring gear.

(b) Heat the ring gear in water that is approximately 100°C (212°F).

(c) Carefully remove the ring gear from the boiling water.

(d) After the moisture on the ring gear has completely evaporated, quickly install the ring gear to the differential case.

|

(e) Align the matchmarks on the ring gear with those of the differential case. Text in Illustration

|

|

(f) After the ring gear cools down, apply thread lock adhesive to the 10 set bolts and install them.

Adhesive:

Toyota Genuine Adhesive 1360K, Three Bond 1360K or equivalent

Torque:

115 N·m {1173 kgf·cm, 85 ft·lbf}

8. INSTALL FRONT DIFFERENTIAL CASE BEARING

(a) Using SST and a press, press the 2 bearings (inner) into the differential case.

SST: 09950-60010

09951-00520

09951-00610

SST: 09950-70010

09951-07150

9. INSTALL FRONT DIFFERENTIAL CASE BEARING

HINT:

Use the same differential case bearings that were previously installed to the vehicle.

|

(a) Using SST and a press, press the case bearing (outer race) into the differential case bearing retainer. SST: 09950-60020 09951-00810 SST: 09950-70010 09951-07150 Text in Illustration

|

|

|

(b) Using SST and a press, press the case bearing (outer) into the differential carrier. SST: 09950-60020 09951-00810 SST: 09950-70010 09951-07150 Text in Illustration

|

|

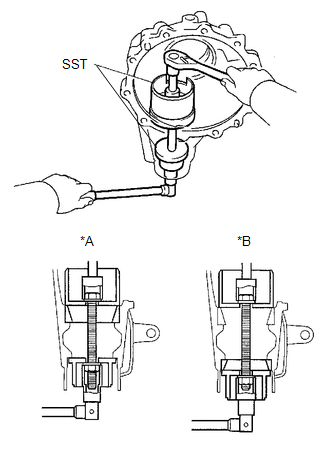

10. INSTALL FRONT DRIVE PINION REAR TAPERED ROLLER BEARING (OUTER)

(a) Using SST, install the front drive pinion rear tapered roller bearing (outer race).

SST: 09950-00020

09951-00890

09951-00680

Text in Illustration|

*A |

for Rear |

|

*B |

for Front |

11. INSTALL FRONT DRIVE PINION FRONT TAPERED ROLLER BEARING

(a) Using a brass bar and hammer, tap in the oil storage ring.

(b) Using SST, install the front drive pinion front tapered roller bearing (outer race).

SST: 09950-00020

09951-00890

09951-00680

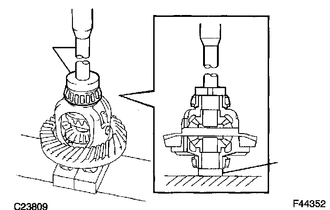

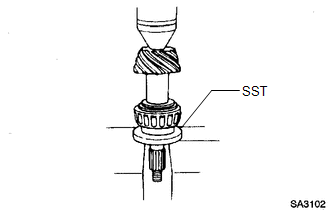

12. INSTALL FRONT DRIVE PINION FRONT TAPERED ROLLER BEARING

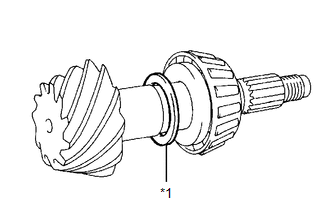

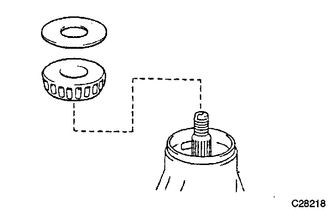

(a) Install the washer to the drive pinion.

(b) Using SST and a press, press the front bearing onto the drive pinion.

SST: 09506-30012

13. INSPECT DIFFERENTIAL DRIVE PINION PRELOAD

(a) Install the drive pinion, roller bearing and oil slinger to the differential case.

HINT:

Install the spacer, oil storage ring and oil seal after adjusting the gear contact pattern.

|

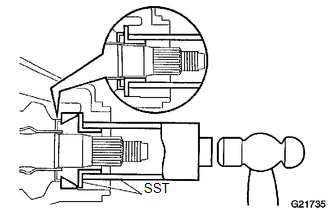

(b) Using SST, install the companion flange. SST: 09950-30012 09951-03010 09953-03010 09954-03010 09955-03030 09956-03020 NOTICE: Before using SST (center bolt), apply hypoid gear oil to its threads and tip. |

|

(c) Adjust the drive pinion preload by tightening the companion flange nut.

|

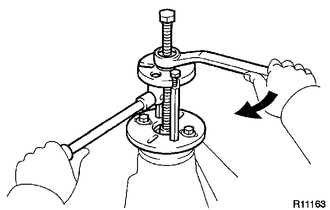

(d) Using SST to hold the flange in place, tighten the nut. SST: 09330-00021 NOTICE:

Torque: 370 N*m (3773 kgf*cm, 273 ft.*lbf) or less |

|

|

(e) Using a torque wrench, measure the preload. Standard Preload (at Starting):

NOTICE: For a more accurate measurement, rotate the bearing forward and backward several times before measuring. |

|

14. INSTALL DIFFERENTIAL CASE ASSEMBLY

15. ADJUST DIFFERENTIAL RING GEAR BACKLASH

(a) Install the side bearing retainer with the 10 bolts.

Torque:

75 N·m {765 kgf·cm, 55 ft·lbf}

|

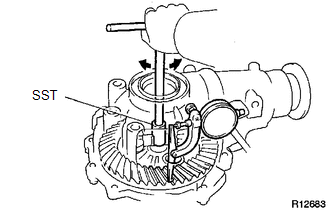

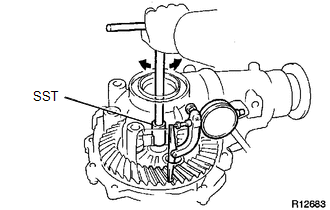

(b) Using SST and a dial indicator, measure the ring gear backlash. SST: 09564-32011 Standard backlash: 0.11 to 0.21 mm (0.00433 to 0.00827 in.)

|

|

16. INSPECT TOTAL PRELOAD

(a) Using a torque wrench, measure the preload with the teeth of the drive pinion and ring gear in contact.

Standard Total Preload (at Starting):

|

Item |

Specified Condition |

|---|---|

|

New bearing |

1.2 to 2.8 N*m (13 to 28 kgf*cm, 11 to 24 in.*lbf) |

|

Used bearing |

0.71 to 1.66 N*m (7.2 to 17 kgf*cm, 6.3 to 14.7 in.*lbf) |

- If necessary, disassemble and inspect the differential.

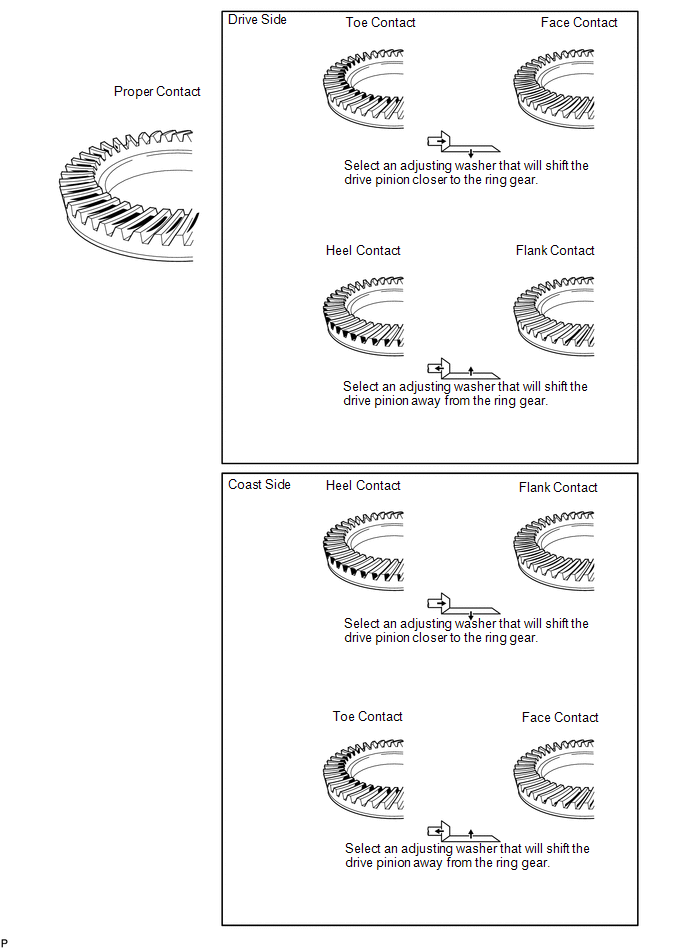

17. ADJUST TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION

(a) Remove the differential case bearing retainer and differential case.

|

(b) Coat 3 or 4 teeth at 3 different positions on the ring gear with Prussian blue. |

|

(c) Install the differential case and differential case bearing retainer.

Torque:

75 N·m {765 kgf·cm, 55 ft·lbf}

(d) Hold the companion flange firmly in place and rotate the ring gear in both directions.

(e) Remove the differential case bearing retainer and differential case.

(f) Inspect the tooth contact pattern.

|

(g) If the teeth are not contacting properly, use the following chart to select an appropriate washer. Text in Illustration

Standard Washer:

|

|

18. REMOVE FRONT DRIVE PINION COMPANION FLANGE NUT

.gif)

19. REMOVE FRONT DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY

.gif)

20. REMOVE FRONT DIFFERENTIAL DRIVE PINION OIL SLINGER

21. REMOVE FRONT DRIVE PINION REAR TAPERED ROLLER BEARING (INNER)

.gif)

22. REMOVE FRONT DRIVE PINION REAR TAPERED ROLLER BEARING (OUTER)

.gif)

23. REMOVE FRONT DIFFERENTIAL DRIVE PINION BEARING SPACER

.png)

(a) Remove the front differential drive pinion bearing spacer.

24. INSTALL FRONT DIFFERENTIAL OIL STORAGE RING

.gif)

25. INSTALL FRONT DRIVE PINION REAR TAPERED ROLLER BEARING (OUTER)

(a) Using SST and a hammer, install the roller bearing (outer).

SST: 09316-60011

09316-00011

09316-00021

26. INSTALL FRONT DRIVE PINION REAR TAPERED ROLLER BEARING (INNER)

(a) Install the roller bearing (inner).

27. INSTALL FRONT DIFFERENTIAL DRIVE PINION OIL SLINGER

28. INSTALL FRONT DIFFERENTIAL CARRIER OIL SEAL

(a) Apply MP grease to the lip of a new oil seal.

|

(b) Using SST and a hammer, tap in the oil seal. SST: 09554-22010 Standard oil seal depth: 2.7 to 3.3 mm (0.106 to 0.130 in.) Text in Illustration

|

|

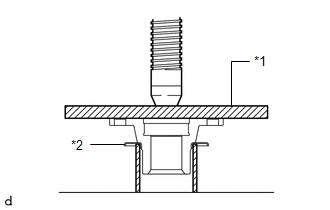

29. INSTALL FRONT DIFFERENTIAL DUST DEFLECTOR

(a) Using a steel plate and press, press in a new dust deflector.

Text in Illustration|

*1 |

Plate |

|

*2 |

Dust Deflector |

NOTICE:

Do not damage the dust deflector.

30. INSTALL FRONT DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY

(a) Place the companion flange on the drive pinion.

(b) Coat the threads of a new nut with hypoid gear oil.

(c) Using SST, install the companion flange.

SST: 09950-30012

09951-03010

09953-03010

09954-03010

09955-03030

09956-03020

NOTICE:

Before using SST (center bolt), apply hypoid gear oil to its threads and tip.

|

(d) Using SST to hold the companion flange in place, tighten the nut to the correct torque. SST: 09330-00021 09330-00030 Torque: 370 N*m (3773 kgf*cm, 273 ft.*lbf) or less |

|

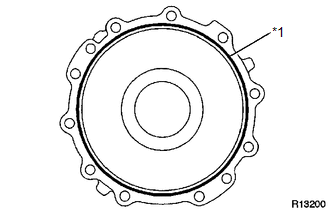

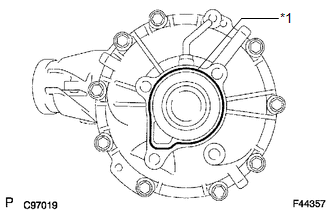

31. INSTALL DIFFERENTIAL SIDE BEARING RETAINER

(a) Remove any old FIPG material from the side bearing retainer.

NOTICE:

Do not drop oil on the contact surfaces of the differential carrier and side bearing retainer.

(b) Wipe off any residual FIPG material on the contact surface using gasoline or alcohol.

|

(c) Apply seal packing to the side bearing retainer as shown in the illustration. Seal packing: Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Text in Illustration

HINT: Install the side bearing retainer within 3 minutes of applying seal packing. |

|

(d) Install the side bearing retainer with new 10 bolts.

Torque:

75 N·m {765 kgf·cm, 55 ft·lbf}

32. INSPECT DRIVE PINION PRELOAD

(a) Using a torque wrench, measure the preload of the backlash between the drive pinion and ring gear.

Standard Preload (at Starting):

|

Item |

Specified Condition |

|---|---|

|

New bearing |

1.08 to 2.02 N*m (12 to 20 kgf*cm, 10 to 17 in.*lbf) |

|

Used bearing |

0.59 to 0.88 N*m (7 to 8 kgf*cm, 6 to 7 in.*lbf) |

- If the preload is more than the maximum, replace the bearing spacer.

- If the preload is less than the minimum, retighten the nut with 13 N*m (130 kgf*cm, 9 ft.*lbf) of torque at a time until the specified preload is reached.

Torque:

370 N*m (3773 kgf*cm, 273 ft.*lbf) or less

- If the maximum torque is exceeded while retightening the nut, replace

the bearing spacer and repeat the preload adjusting procedure.

HINT:

Do not loosen the pinion nut to reduce the preload.

33. INSPECT TOTAL PRELOAD

(a) Using a torque wrench, measure the preload with the teeth of the drive pinion and ring gear in contact.

Standard Total Preload (at Starting):

|

Item |

Specified Condition |

|---|---|

|

New bearing |

1.3 to 2.9 N*m (14 to 29 kgf*cm, 12 to 25 in.*lbf) |

|

Used bearing |

0.81 to 1.76 N*m (9 to 17 kgf*cm, 8 to 15 in.*lbf) |

- If necessary, disassemble and inspect the differential.

34. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using SST and a dial indicator, measure the ring gear backlash.

SST: 09564-32011

Standard backlash:

0.11 to 0.21 mm (0.0043 to 0.00827 in.)

- If the backlash is not within the specification, adjust the side bearing preload.

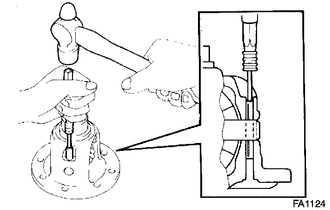

35. INSPECT FRONT DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY

.png)

(a) Using a dial indicator, measure the runout of the companion flange vertically and laterally.

Distance from center to runout measurement point:

30 mm (1.18 in.)

Maximum Runout:

|

Item |

Specified Condition |

|---|---|

|

Vertical runout |

0.10 mm (0.00394 in.) |

|

Lateral runout |

0.10 mm (0.00394 in.) |

|

*a |

Vertical runout |

|

*b |

Lateral runout |

- If the runout is more than the maximum, replace the companion flange.

36. STAKE FRONT DRIVE PINION COMPANION FLANGE NUT

(a) Using a chisel and hammer, stake the drive pinion nut.

37. INSTALL DIFFERENTIAL SIDE GEAR SHAFT OIL SEAL

(a) Coat the lip of a new oil seal with MP grease.

(b) Using SST and a plastic-faced hammer, tap in the oil seal until its surface is flush with the differential carrier end.

SST: 09608-32010

Oil seal depth:

-0.45 to 0.45 mm (-0.018 to 0.018 in.)

38. INSTALL FRONT DIFFERENTIAL SIDE BEARING RETAINER DEFLECTOR

(a) Using a brass bar and hammer, tap in the side bearing retainer deflector.

NOTICE:

Install the side bearing retainer deflector so that it is facing in the correct direction.

39. INSTALL DIFFERENTIAL SIDE GEAR INTER SHAFT SUB-ASSEMBLY (w/ A.D.D.)

(a) Install a new snap ring to the side gear inter shaft.

(b) Using a plastic-faced hammer, tap the side gear inter shaft into the differential case.

(c) Check that there is 2 to 3 mm (0.0787 to 0.118 in.) of axial play.

(d) Check that the side gear inter shaft cannot be completely pulled out by hand.

40. INSTALL FRONT DIFFERENTIAL TUBE ASSEMBLY

(a) Remove any old FIPG material from the contact surfaces of the differential and clutch case.

NOTICE:

Do not drop oil on the contact surfaces of the differential and clutch case.

(b) Wipe off any residual FIPG material on the contact surface using gasoline or alcohol.

|

(c) Apply seal packing to the differential as shown in the illustration. Seal packing: Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Text in Illustration

HINT: Install the differential tube within 3 minutes of applying seal packing. |

|

(d) Install the differential tube to the differential.

(e) Clean the threads of the 4 bolts and retainer bolt holes with toluene or trichloroethylene.

(f) Apply adhesive to 2 or 3 threads at the tip of each bolt.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

(g) Using an E14 "TORX" socket wrench, install the 4 bolts.

Torque:

110 N·m {1122 kgf·cm, 81 ft·lbf}

41. INSTALL AUTOMATIC DISCONNECTING DIFFERENTIAL ACTUATOR (w/ A.D.D.)

(a) Remove any FIPG material from the contact surfaces of the differential and clutch case. Also, do not drop oil on the contact surfaces.

(b) Wipe off residual FIPG material on the contact surfaces using gasoline or alcohol.

|

(c) Apply seal packing to the differential tube as shown in the illustration. Seal packing: Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Text in Illustration

HINT: Install the actuator within 3 minutes of applying seal packing. |

|

(d) Clean the threads of the 4 bolts and retainer bolt holes with toluene or trichloroethylene.

(e) Install the actuator to the differential tube.

(f) Apply adhesive to 2 or 3 threads at the tip of each bolt.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

(g) Install the 4 bolts.

Torque:

21 N·m {210 kgf·cm, 15 ft·lbf}

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using SST and a dial indicator, measure the ring gear backlash.

SST: 09564-32011

Standard backlash:

0.11 to 0.21 mm (0.004 ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT DIFFERENTIAL CARRIER ASSEMBLY

(a) Install the front No. 3 differential support with the 2 bolts.

Torque:

108 N·m {1101 kgf·cm, 80 ft·lbf}

(b) Install ...

Other materials about Toyota 4Runner:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

NOTICE:

Perform brake fluid replacement with the shift lever in P and the parking

brake set.

Perform brake fluid replacement while adding fluid to maintain the fluid

level between the MIN and MAX lines ...

0.0081