Toyota 4Runner: Security Horn Assembly

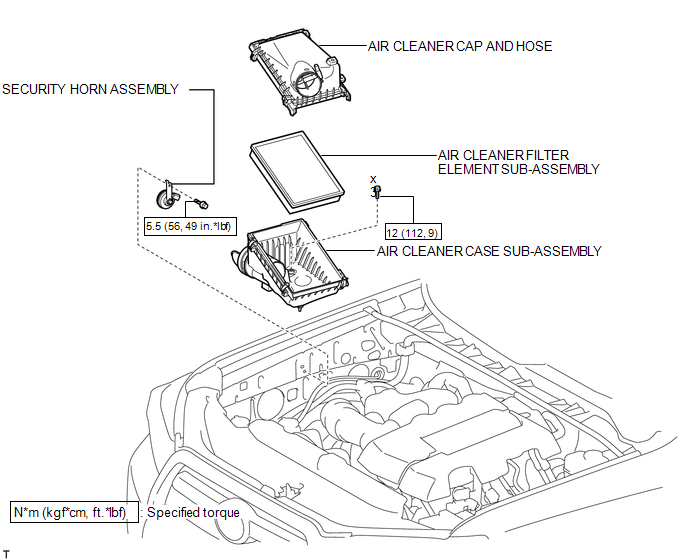

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE AIR CLEANER CAP AND HOSE

.gif)

2. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

.gif)

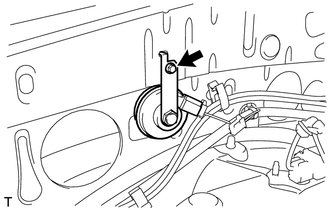

3. REMOVE SECURITY HORN ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the bolt and horn.

Inspection

INSPECTION

PROCEDURE

1. INSPECT SECURITY HORN ASSEMBLY

(a) Apply battery voltage to the horn connector and check the operation of the horn.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → Terminal 1 Battery negative (-) → Horn bracket |

Horn sounds |

If the result is not as specified, replace the security horn assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL SECURITY HORN ASSEMBLY

(a) Install the horn with the bolt.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(b) Connect the connector.

2. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

.gif)

3. INSTALL AIR CLEANER CAP AND HOSE

.gif)

Id Code Box

Id Code Box

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL ID CODE BOX

(a) Attach the 2 claws and move the ID code box in the direction of the

arrow. ...

Security Indicator Light Assembly

Security Indicator Light Assembly

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 2 INSTRUMENT CLUSTER FINISH PANEL GARNISH

2. REMOVE SECURITY INDICATOR LIGHT ASSEMBLY

(a) Pull th ...

Other materials about Toyota 4Runner:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE SHIFT SOLENOID VALVE SR

(a) Remove the 2 bolts and solenoid valve.

2. REMOVE SHIFT SOLENOID VALVE SLU

(a) Remove the bolt, solenoid lock plate and 2 straight p ...

Zero Point Calibration of Acceleration Sensor Undone (C1879/79)

DESCRIPTION

The stabilizer control ECU receives the yaw rate and acceleration sensor zero

point information from the skid control ECU via CAN communication.

DTC Code

DTC Detection Condition

Trouble Area

C18 ...

0.0242